Method and apparatus for simulation test of gas temperature control valve

A technology for simulating testing and testing devices, applied in the field of testing the opening and closing performance of gas valves, can solve problems such as low work efficiency, complex testing devices, long testing time, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

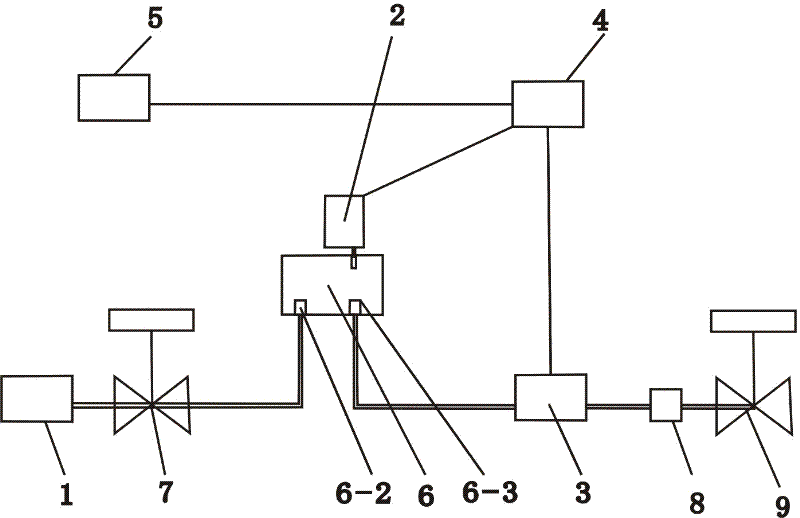

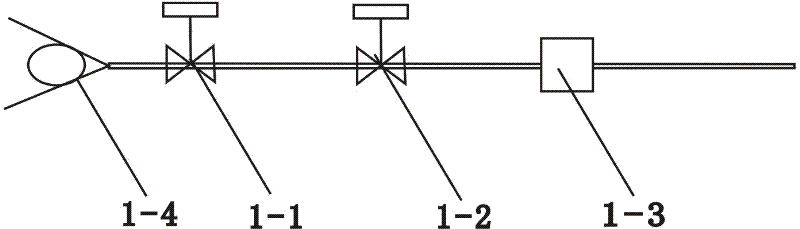

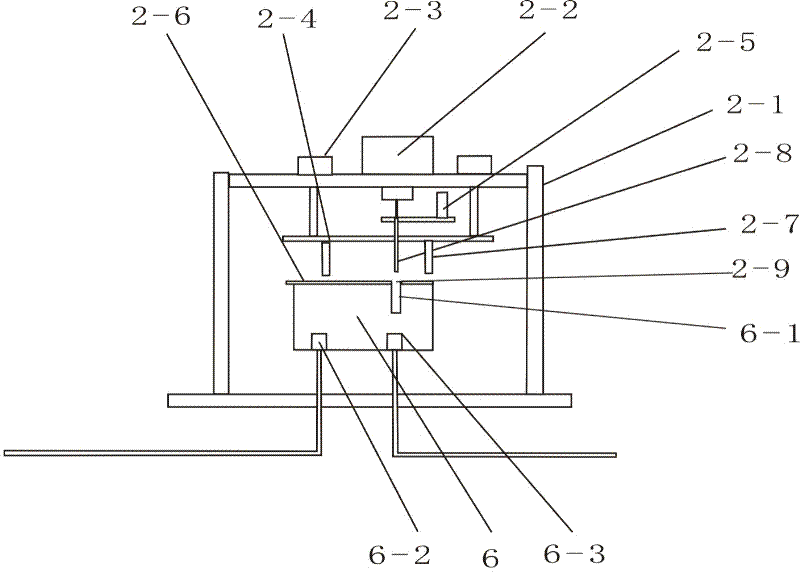

[0016] The simulation test method of the gas temperature control valve of the present invention uses air as the test medium, replaces the volume expansion and contraction of the temperature sensing element with the linear drive of the linear stepping motor to generate a linear displacement, and moves the moving rod of the gas temperature control valve to control the temperature. Control the flow rate of the valve and the opening and closing of the valve port to achieve the purpose of changing the gas flow and opening and closing; and the number of motor pulses under the same flow rate corresponds to the equivalent actual temperature, and the characteristic curve of temperature and flow rate is displayed on the display; The standard range for good curve judgment can automatically judge whether the function curve of the test valve meets the requirements.

[0017] The speed of the linear stepper motor is adjustable, and the high speed can be set during the idle stroke, which can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com