Wet-process desulphurization gypsum drying treatment device

A technology of drying treatment and wet desulfurization, which is used in drying gas arrangement, preliminary treatment to promote drying of solid materials, drying of solid materials, etc. Long-term operation, elimination of clogging and scaling, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

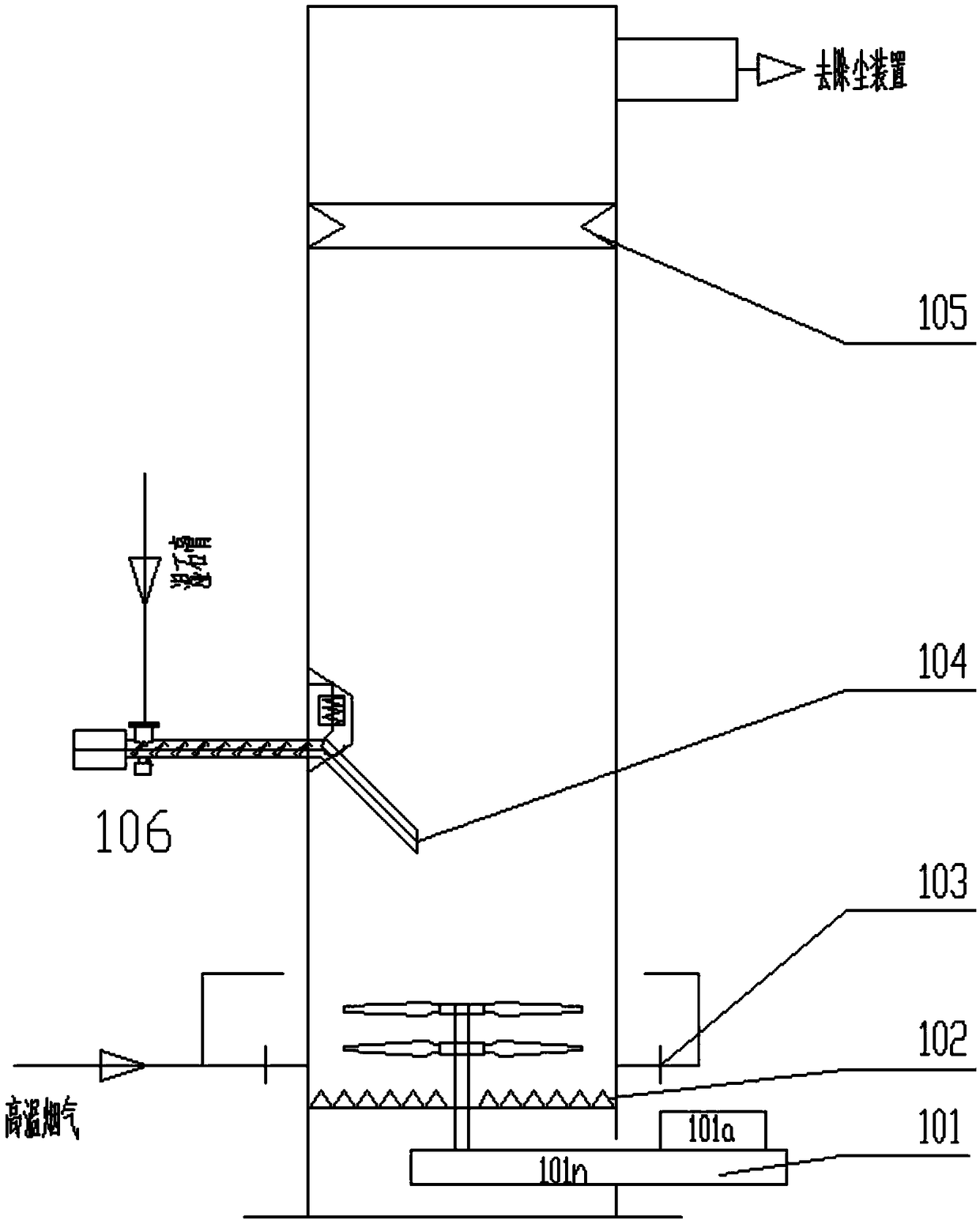

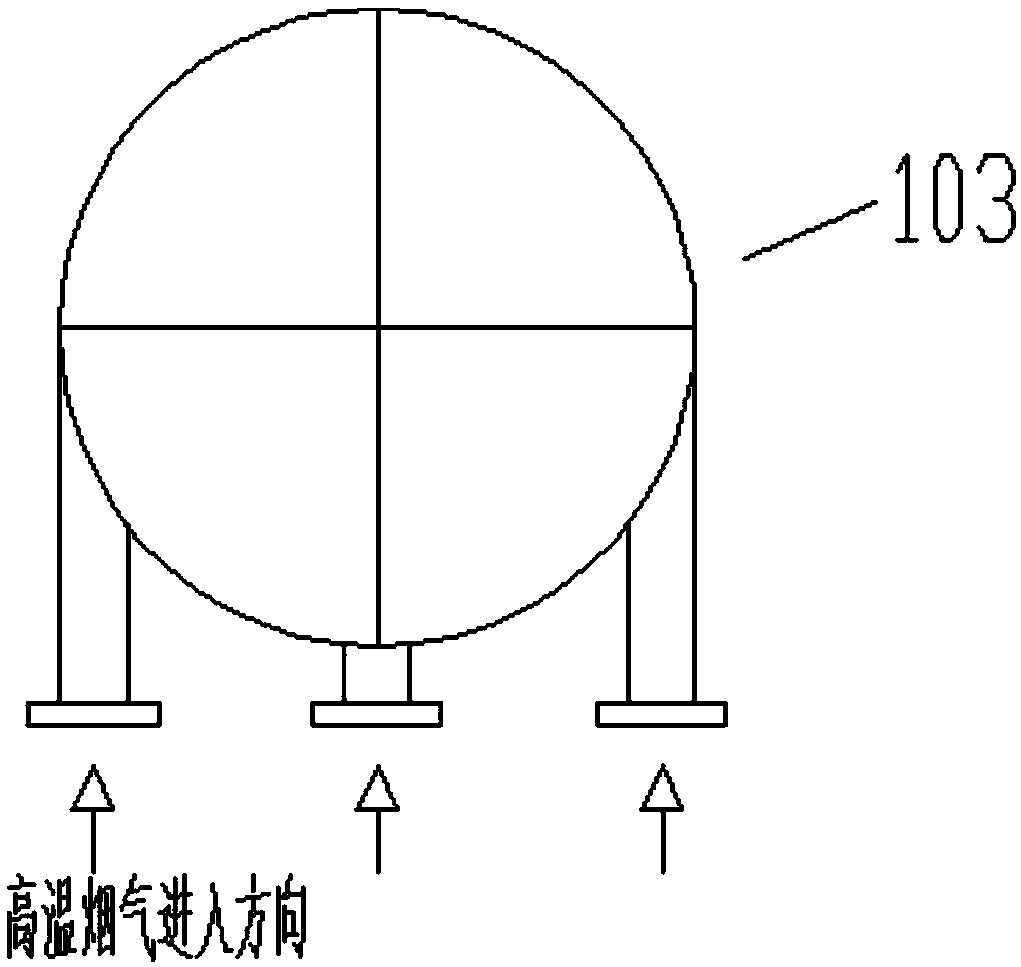

[0026] see Figure 1-Figure 2 , a wet desulfurization gypsum drying treatment device, including a drying cylinder, the bottom of the drying cylinder is provided with a broken arch triangle plate 102, and an agitator is arranged above the arch broken triangle plate; the side wall of the drying cylinder is located at the height of the agitator. There is a high-temperature flue gas inlet, and a wet gypsum inlet is provided above the high-temperature flue gas inlet; a high-temperature flue gas outlet is provided on the top of the drying cylinder, and the high-temperature flue gas outlet is connected to the dust removal device; the flue gas entering the high-temperature flue gas inlet is tar or Pitch high temperature coke oven flue gas.

[0027] In this example, see figure 1 , the drying cylinder is located below the high-temperature flue gas outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com