Single well metering method and device

A technology of measuring device and measuring method, which is used in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of inaccurate measurement, large gas influence, damage to measuring instruments, etc., and achieves reliable work, long service life, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

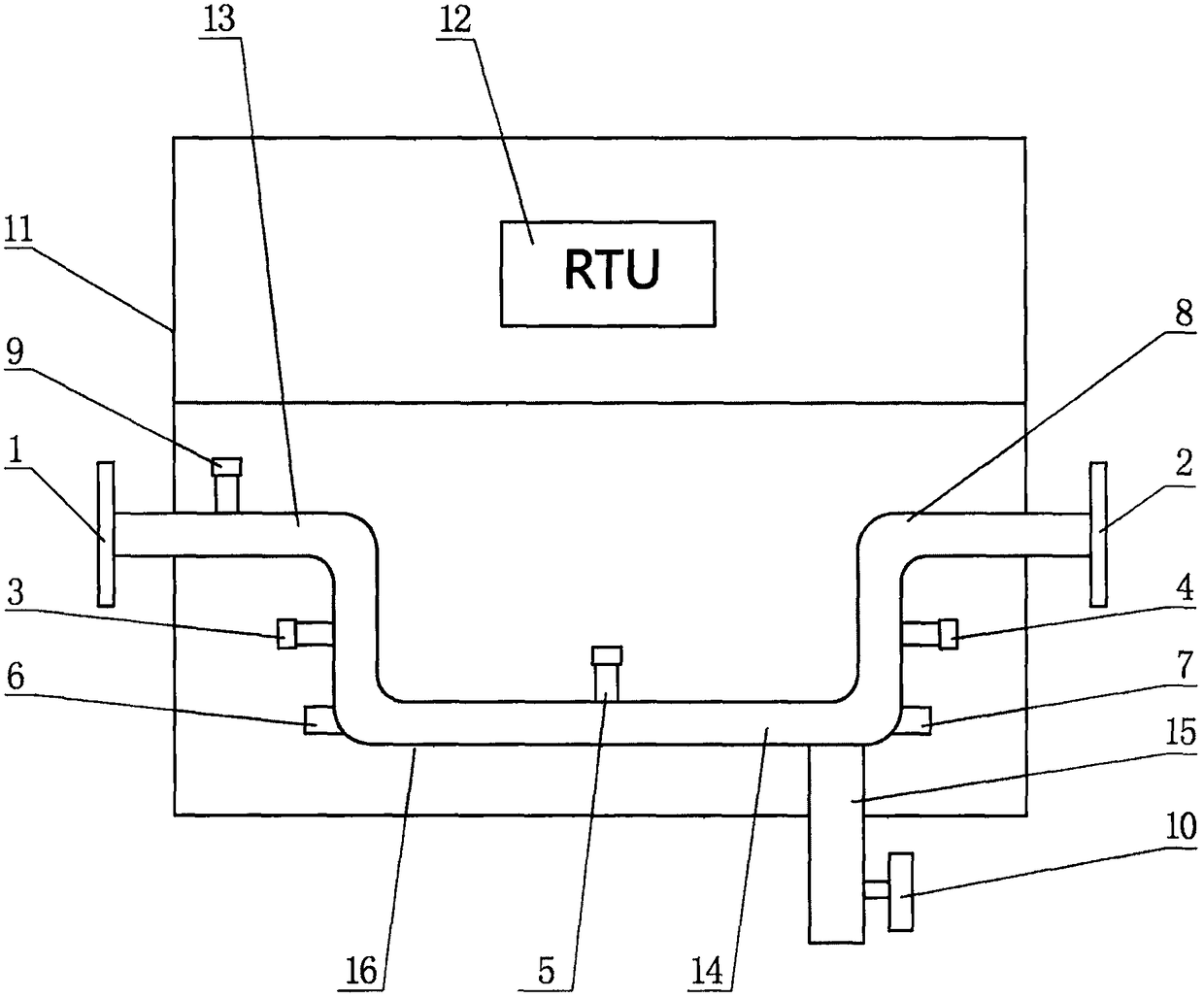

[0019] like figure 1 As shown, the single well metering device includes, anti-theft incubator 11, RTU12 and metering pipeline 16, metering pipeline 16 is fixed on the inner lower end of the anti-theft incubator 11 by screws, and RTU12 is fixed on the top of the anti-theft incubator 11 by screws. The metering pipeline 16 is formed by welding the inlet pipeline 13, the heating pipeline 14 and the outlet pipeline 8 in sequence. The inlet flange 1 is welded on the left side of the inlet pipeline 13. The inlet pipeline 13 is connected with the oil pipe inlet pipeline through the inlet flange 1. The upper part of the inlet pipeline 13 is The electromagnetic wave sensor 9 is installed by threads. The first temperature sensor 3 and the second temperature sensor 4 are installed by threads in the middle part of both sides of the heating pipeline 14; An explosion-proof and flame-retardant heating device 6 and an explosion-proof and flame-retardant heating device 7 are installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com