Oxalate nanosheet array thin-film electrode and preparation method thereof

A nanosheet array and thin-film electrode technology, applied in the direction of electrodes, nanotechnology, nanotechnology, etc., to achieve the effects of high electrochemical activity, small contact resistance, and simplified assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

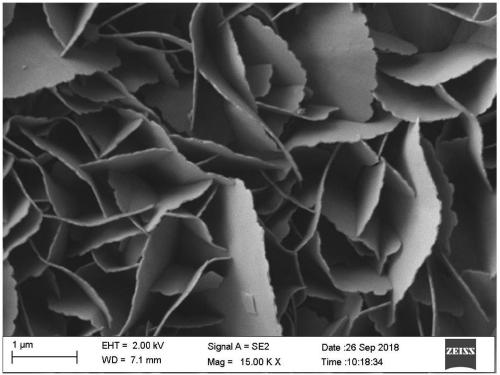

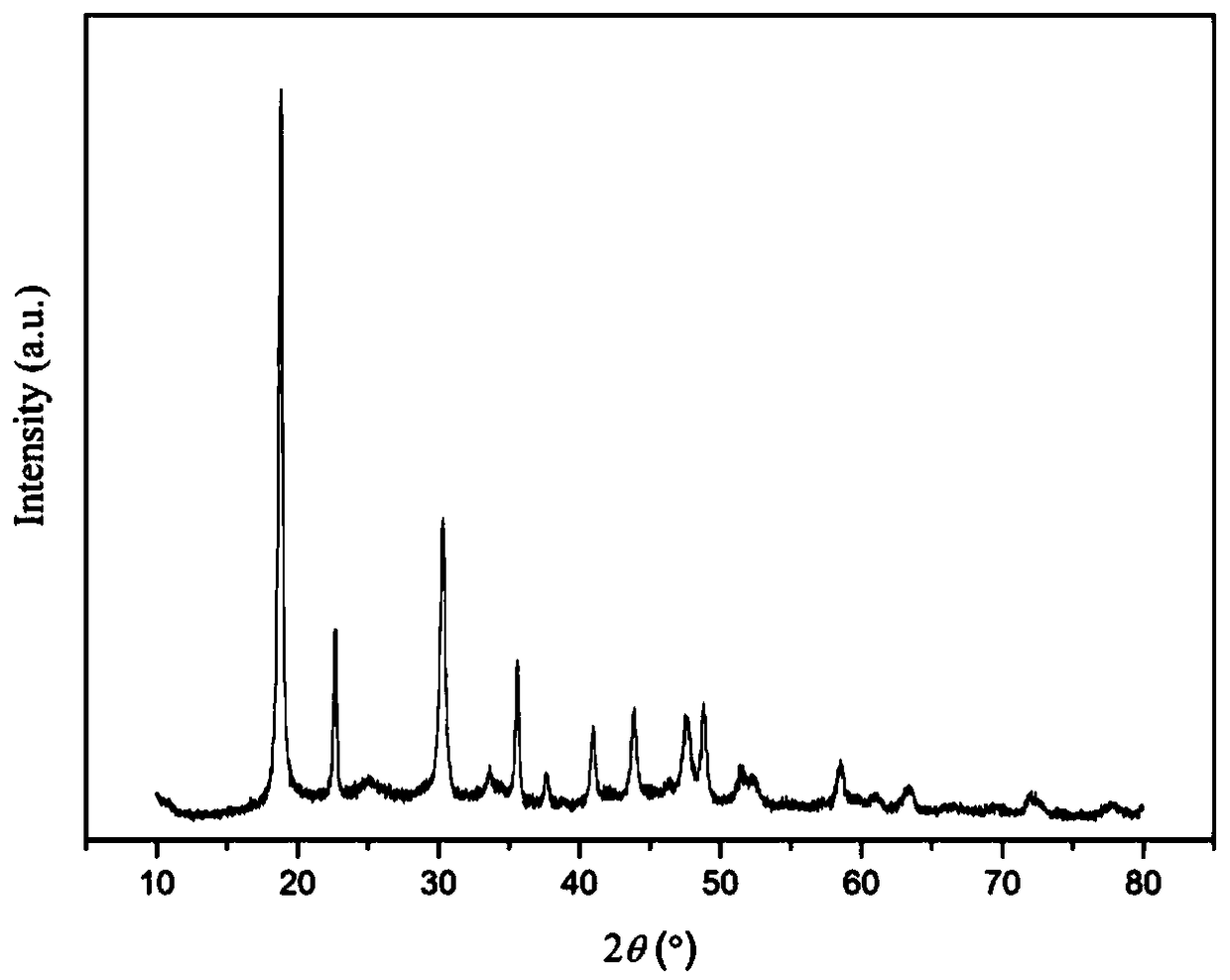

Embodiment 1

[0035] Ultrasonic etching treatment of the conductive substrate: wash the foamed nickel with absolute ethanol and deionized water in sequence, place the foamed nickel after deionized water cleaning in a 3.0mol / L hydrochloric acid solution for 20 minutes, and ultrasonically etch The foamed nickel after etching is cleaned with deionized water;

[0036] Preparation of oxalate nanosheet array thin film electrodes:

[0037]Step 1. Add 70 mL of deionized water to a 100 mL hydrothermal kettle, then add 2 mmol of ammonium oxalate, stir magnetically for 30 minutes, then add 2 mmol of nickel nitrate, and stir magnetically for 20 minutes to obtain a mixed solution;

[0038] Step 2. Put the nickel foam treated by ultrasonic etching into the mixed solution of step 1, seal the hydrothermal kettle to carry out hydrothermal reaction; the temperature of hydrothermal reaction is 140°C, and the time of hydrothermal reaction is 4h;

[0039] Step 3, taking out the nickel foam, rinsing with deioni...

Embodiment 2

[0043] Ultrasonic etching treatment of the conductive substrate: wash the foamed nickel with absolute ethanol and deionized water in sequence, place the foamed nickel after deionized water cleaning in a 3.0mol / L hydrochloric acid solution for 20 minutes, and ultrasonically etch The foamed nickel after etching is cleaned with deionized water;

[0044] Preparation of oxalate nanosheet array thin film electrodes:

[0045] Step 1. Add 70 mL of deionized water to a 100 mL hydrothermal kettle, then add 2 mmol of ammonium oxalate, stir magnetically for 30 minutes, then add 2 mmol of nickel nitrate, and stir magnetically for 20 minutes to obtain a mixed solution;

[0046] Step 2. Put the nickel foam treated by ultrasonic etching into the mixed solution of step 1, seal the hydrothermal kettle to carry out hydrothermal reaction; the temperature of hydrothermal reaction is 140°C, and the time of hydrothermal reaction is 15h;

[0047] Step 3, taking out the nickel foam, rinsing with deio...

Embodiment 3

[0050] Ultrasonic etching treatment of the conductive substrate: wash the foamed nickel with absolute ethanol and deionized water in sequence, place the foamed nickel after deionized water cleaning in a 3.0mol / L hydrochloric acid solution for 20 minutes, and ultrasonically etch The foamed nickel after etching is cleaned with deionized water;

[0051] Preparation of oxalate nanosheet array thin film electrodes:

[0052] Step 1. Add 70 mL of deionized water to a 100 mL hydrothermal kettle, then add 2 mmol of ammonium oxalate, stir magnetically for 30 minutes, then add 2 mmol of cobalt nitrate, and stir magnetically for 20 minutes to obtain a mixed solution;

[0053] Step 2. Put the nickel foam treated by ultrasonic etching into the mixed solution of step 1, seal the hydrothermal kettle and carry out hydrothermal reaction. The temperature of hydrothermal reaction is 140°C, and the time of hydrothermal reaction is 4h;

[0054] Step 3, taking out the nickel foam, rinsing with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com