Waterborne smokeless and odorless inorganic nano-ceramic fireproof coating and preparation method thereof

A technology of inorganic nano and fire-resistant coatings, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of escape and rescue threats, coatings that cannot be smokeless and tasteless, and lose fire protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

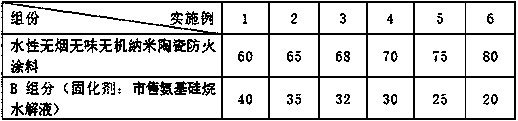

[0040] For the convenience of expression, use the following four tables to express the proportioning and product performance of the 6 embodiments, which are respectively Table 1, a water-based smokeless and tasteless inorganic nano-ceramic fireproof coating raw material mass percentage table; Table 2 A component raw material mass percentage Table; Table 3 water-based inorganic nano-ceramic emulsion by components and weight ratio table respectively; Table 4: the water-based smokeless and odorless inorganic nano-ceramic fireproof coating product performance index table obtained in the above-mentioned Examples 1-6.

[0041] Table 1, a kind of water-based smokeless and tasteless inorganic nano-ceramic fireproof coating raw material component mass percent table:

[0042]

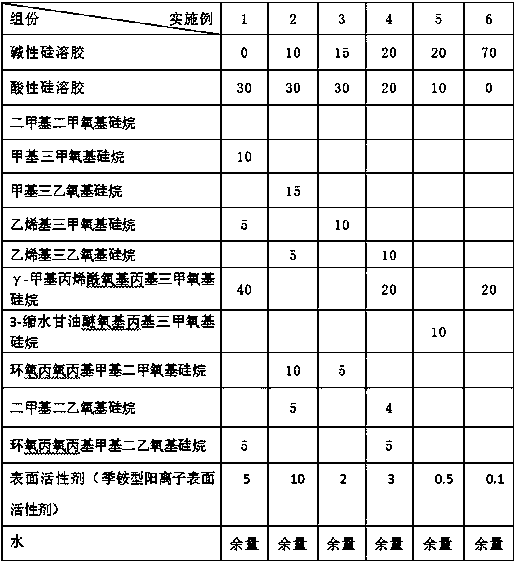

[0043] Table 2: Table of mass percentage of raw materials of component A:

[0044]

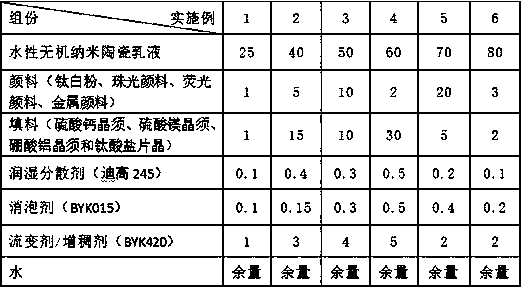

[0045] Table 3, water-based inorganic nano-ceramic emulsion is shown respectively by component and weight ratio:

[0046...

Embodiment 7

[0052] The preparation method of the water-based smokeless and odorless inorganic nano-ceramic fireproof coating is as follows: proportioning according to the content of the components in Examples 1-6,

[0053]The first step is to prepare inorganic nano-ceramic emulsion: first mix one or several silanes, after mixing evenly, add surfactant and stir evenly, then start to add dropwise to the silica sol that has been weighed and fed in advance, within 30 minutes After the internal dripping is completed, then start to heat up, keep the reaction temperature at 35-80 degrees, and react at constant temperature for 2-5 hours, then add metered water, stop heating, lower the temperature and cool down, and the inorganic nano-ceramic with the appearance of semi-milky white transparent viscous liquid can be obtained Lotion;

[0054] The second step is to mix the inorganic nano-ceramic emulsion prepared in the first step with pigments and fillers, and use a high-speed disperser for high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com