Polymer particle preparation method

A polymer and polymer solution technology, applied in biochemical equipment and methods, microsphere preparation, microorganisms, etc., can solve the problems of droplet breakage, particle size distribution widening, and insufficient stirring force, etc., to reduce the surface Tension, good uniformity, and the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

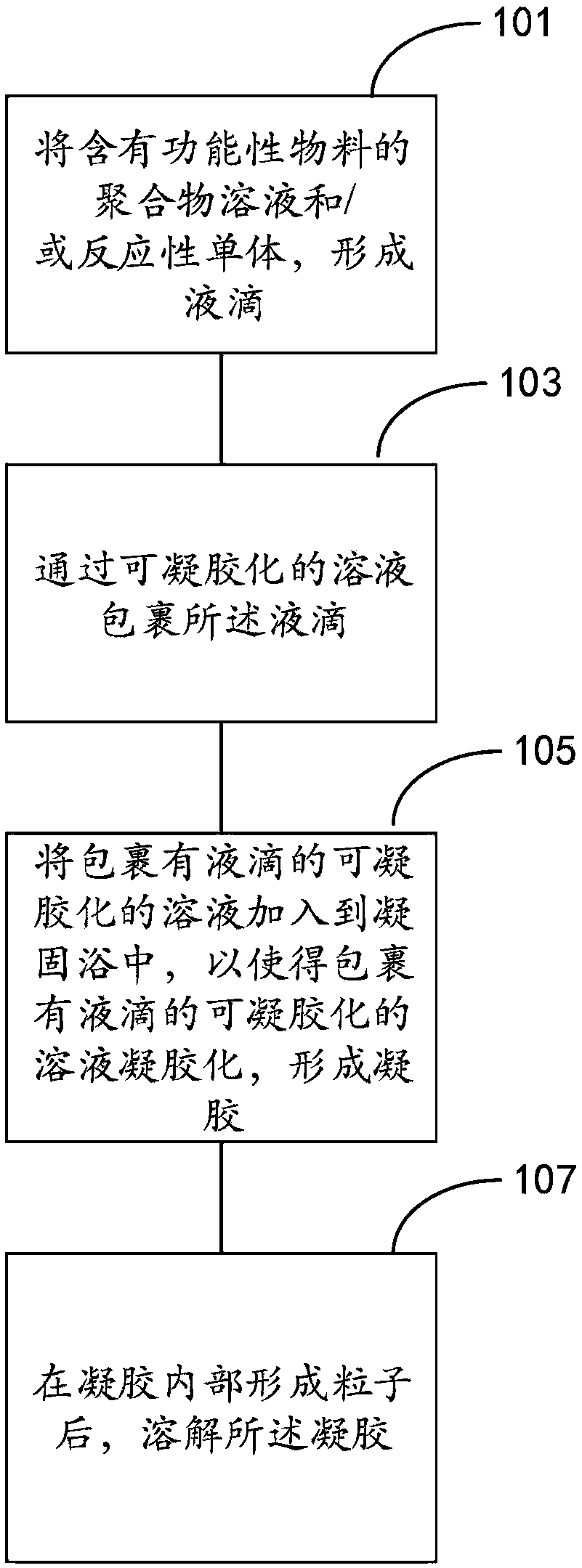

[0062] Please like figure 1 As shown, the embodiment of the present invention provides a method for preparing polymer particles, and the method includes the following steps:

[0063] 101. The polymer solution containing functional materials and / or reactive monomer 71 is formed into droplets 711;

[0064] 103. Wrap the droplets 711 by a gelable solution 72;

[0065] 105. Add the gelable solution 72 wrapped with the droplets 711 into the coagulation bath 73, so that the gelable solution wrapped with the droplets 711 gelatinize 72 to form a gel;

[0066] 107. After forming particles inside the gel, dissolve the gel.

[0067] In the method for preparing polymer particles provided by the embodiments of the present invention, the polymer solution containing functional materials and / or the reactive monomer 71 is the dispersed phase, and the gelable solution 72 is the continuous phase to make the gelable The gelation of the solution 72 is the coagulation bath 73.

[0068] In the prior art, the ...

Embodiment 1

[0100] Example 1: Preparation of drug-loaded polylactic acid-glycolic acid copolymer (PLGA) embolic microspheres for interventional therapy

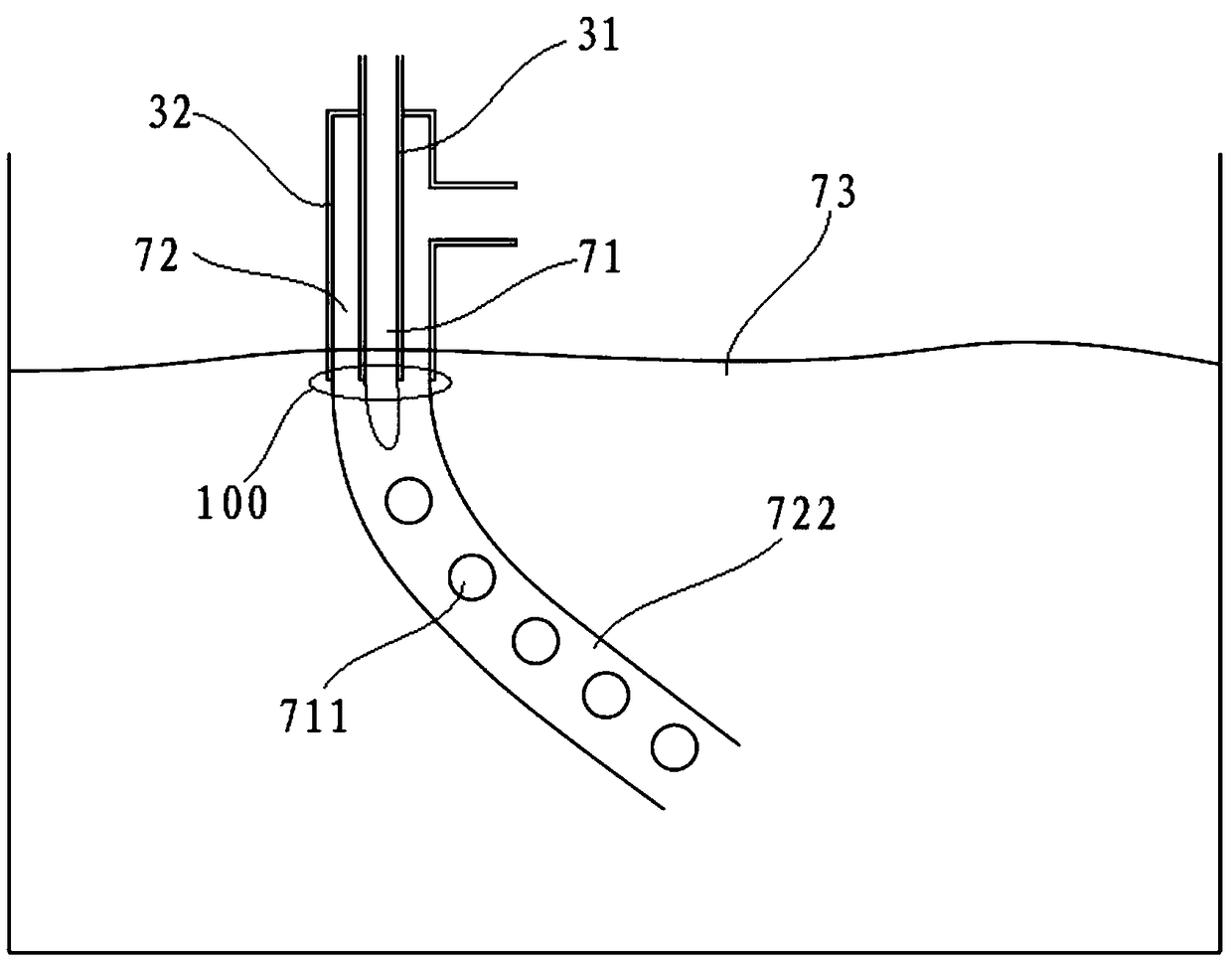

[0101] This embodiment adopts image 3 The droplet 711 shown forms a wrapping device:

[0102] Among them, the inner diameter of the first pipe 31 is 0.25 mm and the outer diameter is 0.48 mm; the inner diameter of the second pipe 32 is 0.75 mm, and the outer diameter is 1.10 mm. The first pipe 31 and the second pipe 32 All were submerged in the coagulation bath 73, and taxol-containing microspheres with diameters of 100 micrometers, 120 micrometers, 160 micrometers, 200 micrometers, 220 micrometers, and 240 micrometers were prepared.

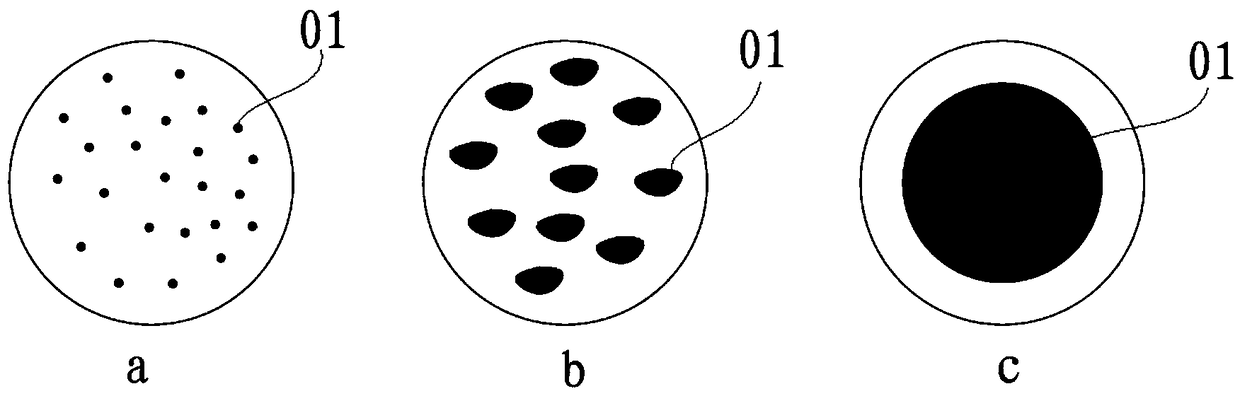

[0103] In this embodiment, the functional material is paclitaxel drug molecules, which are uniformly distributed in the droplets 711 in a homogeneous form.

[0104] Solution preparation: disperse phase solution, dissolve a certain amount of PLGA in chloroform, configure the corresponding solution according to the...

Embodiment 2

[0111] Example 2: Preparation of porous spherical scaffold for cell culture

[0112] The porous spherical cell scaffold needs to have a suitable volume size, and preferably has a through pore structure. Spherical scaffolds have good rolling properties. Cells grow on the surface or in the inner pores. It is suitable for large-scale 3D culture. Only a small amount of cultured microspheres with cells need to be transferred to a large amount of blank spherical medium during cell expansion. It avoids traditional digestion and transfer, greatly reducing the workload. In this embodiment, the functional material is an aqueous solution of porogen sodium bicarbonate, which is dispersed in droplets 711 in a heterogeneous form.

[0113] This embodiment adopts image 3 The shown droplet 711 forms a wrapping device: the inner diameter of the first pipe 31 is 0.35mm and the outer diameter is 0.65mm; the inner diameter of the second pipe 32 is 1.15mm, and the outer diameter is 1.50mm, the prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com