Method and plate flipping milling machine for achieving five-axis gantry horizontal plate flipping milling

A gantry and horizontal technology is applied to a method for realizing five-axis gantry horizontal flap milling and the field of flap milling machines, which can solve the problems of increasing processing auxiliary time errors, low machine tool utilization, affecting production efficiency, and the like. Achieve the effect of solving the storage buffer problem, improving the effective utilization rate, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

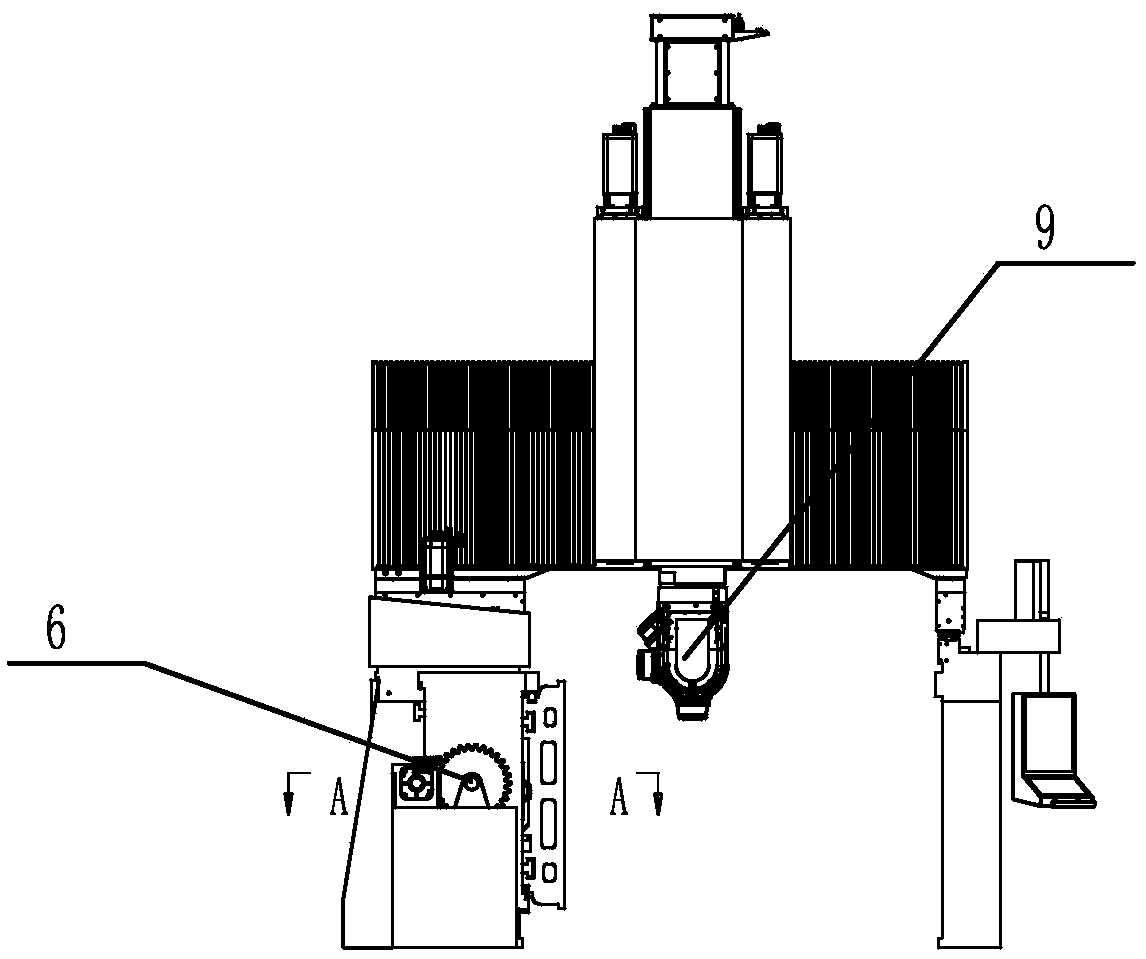

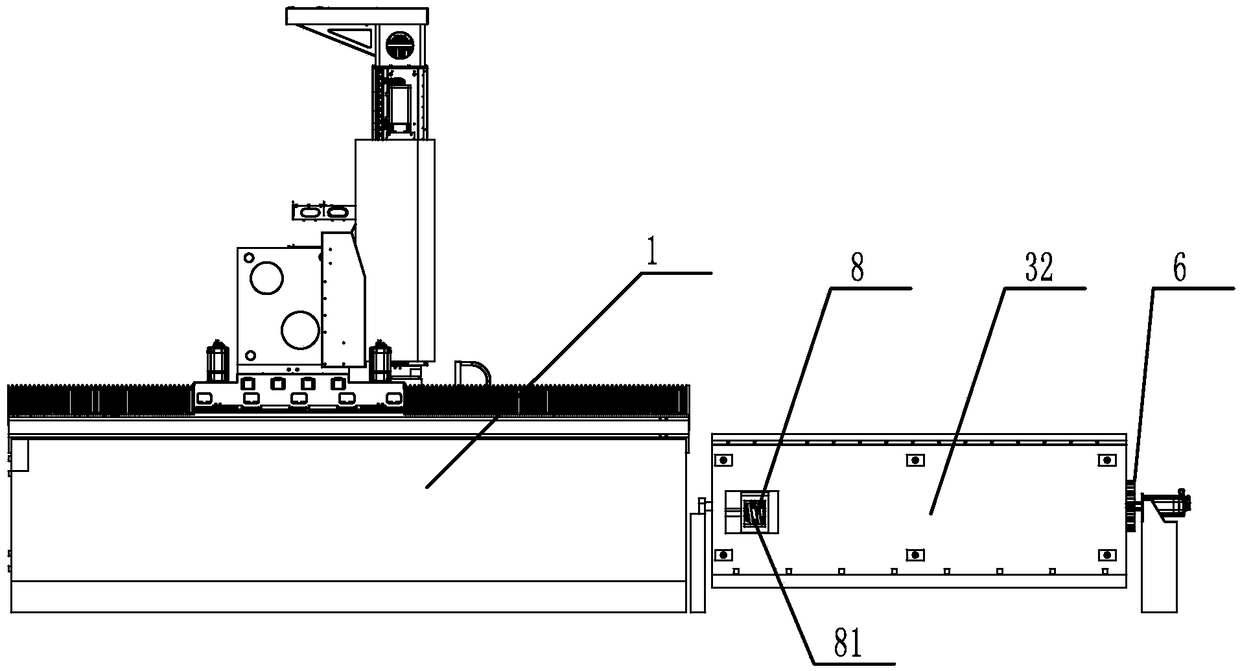

[0031] A method for realizing five-axis gantry horizontal turning milling. The gantry side wall of the gantry milling machine is used as a supporting body shared by the moving beam and the horizontal workbench, and provides linear motion guidance and support for the moving beam and the horizontal workbench. The AC pendulum angle milling head is arranged horizontally, that is, it is set at 90° to form a horizontal machining spindle, which is combined with a horizontally arranged worktable fixed to the side wall of the gantry to form a gantry five-axis horizontal milling machine. The AC pendulum angle The milling head is an AC swing angle universal milling head; a turning table is equipped outside the machine tool, and there is a worktable exchange device between the worktable and the turning table, which constitutes an automatic worktable exchange system. There are three worktable exchange stations, one loading station and one waiting station.

[0032] Such as Figure 1 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com