Composite active carbon material and preparation method thereof

A technology of composite activated carbon and activated carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of ordinary activated carbon fibers such as easy saturation, uneven effluent quality, and diminishing adsorption capacity, and achieves a simple and easy preparation method, Good adsorption and purification ability, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

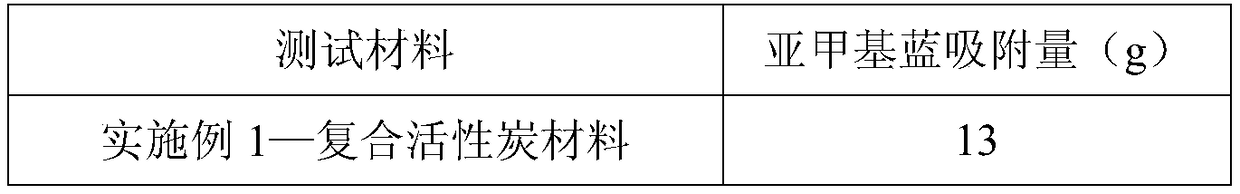

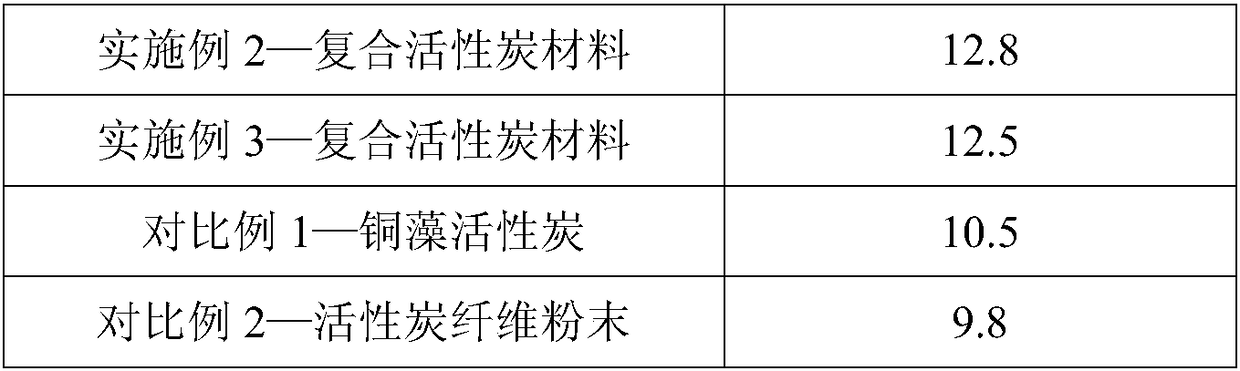

Examples

Embodiment 1

[0031] A composite activated carbon material prepared from the following raw materials in mass percentage:

[0032] 50% powdered activated carbon;

[0033] 30% activated carbon fiber;

[0034] 15% short fibers;

[0035] 5% acrylic glue;

[0036] Wherein, the powdered activated carbon is copper algae activated carbon, the short fiber length is 35 mm, and the weight percentage sum of the above components is 100%.

[0037] Activated carbon fiber is chopped activated carbon fiber, which is pulverized from activated carbon fiber with an iodine value of 1500mg / g.

[0038] Short fibers are selected from natural fibers and are wood pulp.

[0039] A kind of preparation method of composite activated carbon material, the preparation of copper algae activated carbon comprises the following steps:

[0040] (1) Adopt pulverizer to pulverize dry copper algae, sieve powder, select algae powder below 40 orders;

[0041] (2) Use phosphoric acid solution with a mass fraction of 60% to impr...

Embodiment 2

[0050] A composite activated carbon material prepared from the following raw materials in mass percentage:

[0051] 52% powdered activated carbon;

[0052] 35% activated carbon fiber;

[0053] 10% short fibers;

[0054] 3% acrylic glue;

[0055] Wherein, the powdered activated carbon is copper algae activated carbon, the short fiber length is 40 mm, and the weight percentage sum of the above components is 100%.

[0056] Activated carbon fiber is chopped activated carbon fiber, which is pulverized from activated carbon fiber with an iodine value of 1500mg / g.

[0057] The short fibers are selected from natural fibers and are straw pulp.

[0058] A kind of preparation method of composite activated carbon material, the preparation of copper algae activated carbon comprises the following steps:

[0059] (1) Adopt pulverizer to pulverize dry copper algae, sieve powder, select algae powder below 40 orders;

[0060] (2) Use phosphoric acid solution with a mass fraction of 60% to...

Embodiment 3

[0069] A composite activated carbon material prepared from the following raw materials in mass percentage:

[0070] 60% powdered activated carbon;

[0071] 25% activated carbon fibers;

[0072] 13% short fibers;

[0073] 2% acrylic glue;

[0074] Wherein, the powdered activated carbon is copper algae activated carbon, the short fiber length is 50 mm, and the weight percentage sum of the above components is 100%.

[0075] Activated carbon fiber is chopped activated carbon fiber, which is pulverized from activated carbon fiber with an iodine value of 1500mg / g.

[0076] Short fibers are selected from synthetic fibers and are polypropylene fibers.

[0077] A kind of preparation method of composite activated carbon material, the preparation of copper algae activated carbon comprises the following steps:

[0078] (1) Adopt pulverizer to pulverize dry copper algae, sieve powder, select algae powder below 40 orders;

[0079] (2) Use phosphoric acid solution with a mass fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com