Bowel relaxing and toxin expelling stauntonia chinensis fruit enzyme pulp can and production method

A production method, the technology of wild papaya, applied in the field of nutritious food processing, to achieve the effect of increasing volume, increasing quantity and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

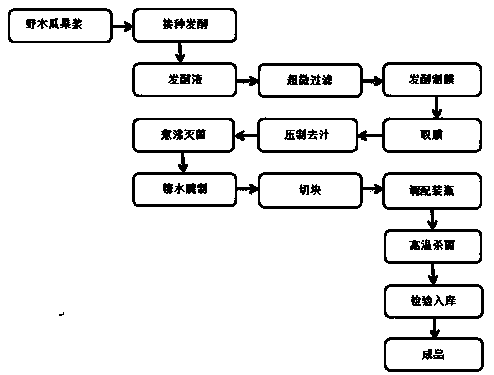

Method used

Image

Examples

Embodiment 1

[0026] 1. Select wild papaya without rot, wash, break and remove seeds, and use a beater to beat to obtain wild papaya pulp; take 10 parts of wild papaya pulp according to the parts by weight, add 80 parts of boiling water, and 10 parts of white sugar, stir and mix evenly Transfer to the ceramic altar, and when the temperature drops to 40°C, add 0.01 part of compound bacterial powder and 0.01 part of compound enzyme to seal, move the ceramic altar to the fermentation workshop, control the temperature of the fermentation workshop to 25°C, and seal and ferment 3 month, during which the altar was opened and stirred once every 10 days; after the fermented wild papaya fermentation liquid was taken and the supernatant was passed through double-layer gauze, a cross-flow filter membrane was used to filter to obtain a clarified filtrate, and the filtrate was poured into a fermentation dish. The depth of the liquid is 5cm, the fermentation plate is covered with gauze, and the fermentatio...

Embodiment 2

[0031] 1. Select wild papaya without rot, wash, break and remove seeds, and use a beater to beat to obtain wild papaya pulp; take 20 parts of wild papaya pulp according to the parts by weight, add 72 parts of boiling water, and 8 parts of white sugar, stir and mix evenly Transfer to the ceramic altar, and when the temperature drops to 45°C, add 0.03 parts of the compound bacteria powder and 0.03 parts of the compound enzyme to seal, move the ceramic altar to the fermentation workshop, control the temperature of the fermentation workshop to 28°C, and seal and ferment 2 month, during which the altar was opened and stirred once every 10 days; after the fermented wild papaya fermentation liquid was taken and the supernatant was passed through double-layer gauze, a cross-flow filter membrane was used to filter to obtain a clarified filtrate, and the filtrate was poured into a fermentation dish. The depth of the liquid is 6cm, the fermentation plate is covered with gauze, and the fer...

Embodiment 3

[0036] 1. Select wild papaya without rot, wash, break and remove seeds, and use a beater to beat to obtain wild papaya pulp; take 30 parts of wild papaya pulp according to the parts by weight, add 60 parts of boiling water, and 10 parts of white sugar, stir and mix evenly Transfer to the ceramic altar, when the temperature drops to 50°C, add 0.05 parts of compound bacteria powder, 0.05 parts of compound enzyme to seal, move the ceramic altar to the fermentation workshop, control the temperature of the fermentation workshop to 30°C, seal and ferment 1 month, during which the altar was opened and stirred once every 10 days; after the fermented wild papaya fermentation liquid was taken and the supernatant was passed through double-layer gauze, a cross-flow filter membrane was used to filter to obtain a clarified filtrate, and the filtrate was poured into a fermentation dish. The depth of the liquid is 5-8cm, and the fermentation plate is covered with gauze, and the fermentation pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com