Transparent liquid variable temperature viscosity coefficient measurement device based on video

A technology for transparent liquids and measuring devices, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as unresolved measurement results, achieve the effects of eliminating measurement errors, saving time and cost, and simplifying the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

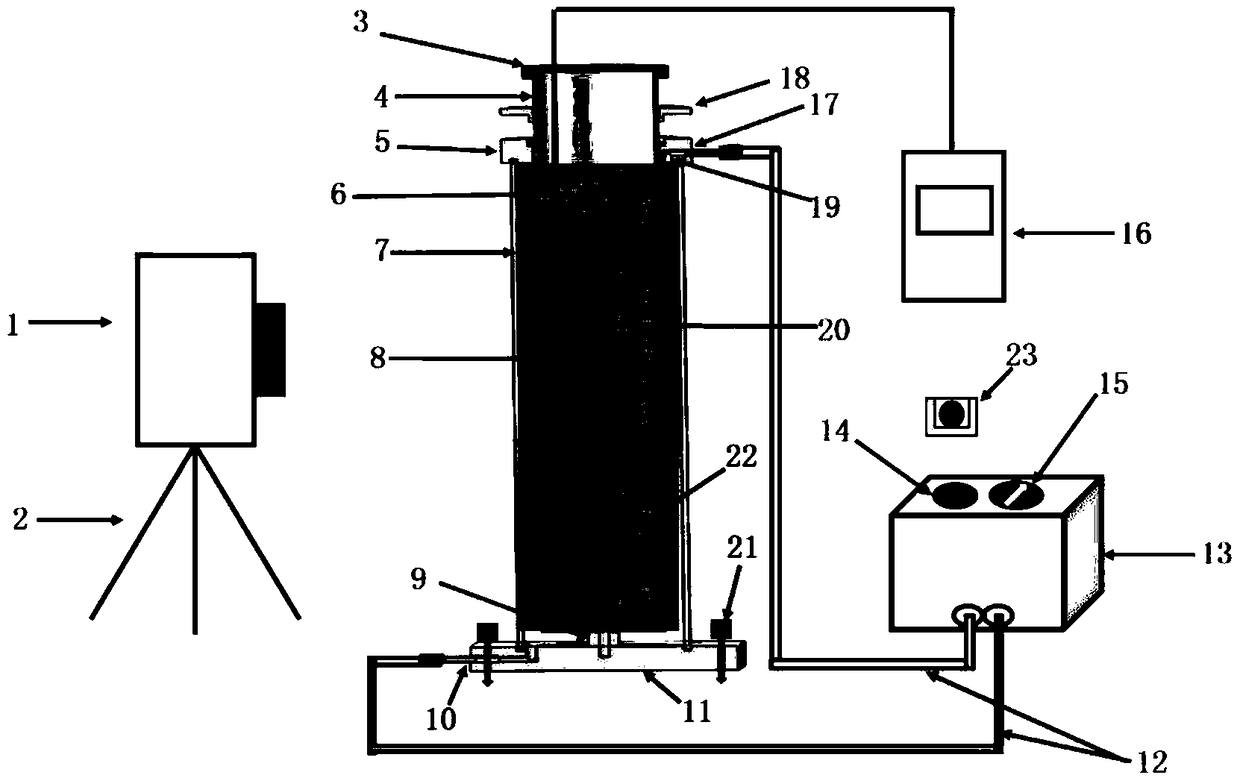

[0035] A video-based device for measuring the variable temperature viscosity coefficient of transparent liquid, including: a camera component, a falling ball test component, a circulating heating medium component and a scale 22,

[0036] The falling ball test assembly is connected to the circulating heating medium assembly,

[0037] One side of the falling ball test assembly is provided with a camera assembly for taking pictures,

[0038] The falling ball test assembly is provided with a scale 22,

[0039]The drop ball test assembly includes: a transparent drop tube cover 3, a vertical transparent drop tube 4, a drop ball 6, a transparent tubular jacket 7, and a heating medium 8, and the transparent drop tube cover 3 is installed on the vertical transparent drop tube 4. A drop ball 6 is built in the vertical transparent drop tube 4 , a transparent tubular jacket 7 is arranged outside the vertical transparent drop tube 4 , and a heating medium 8 is arranged between the vertica...

Embodiment 2

[0050] The invention relates to a video-based measuring device for variable temperature viscosity coefficient of transparent liquid. The devices include:

[0051] The camera assembly is composed of a camera 1 and a height adjustment bracket 2; the camera 1 is connected to a computer and the computer completes parameter settings such as camera resolution and camera rate, dynamic camera control, recording and post-processing. The pixel resolution of the camera 1 determines the accuracy of the falling distance when recording the falling ball movement; the camera rate of the camera 1 determines the time accuracy of recording the falling ball movement; adjust the height adjustment bracket 2 to a reasonable position, and center the vertical transparent falling ball tube 4 The half section is convenient for recording the motion state when the ball falls at a high speed, so as to improve the accuracy of recording the distance and time of the ball falling.

[0052] The falling ball ex...

Embodiment 3

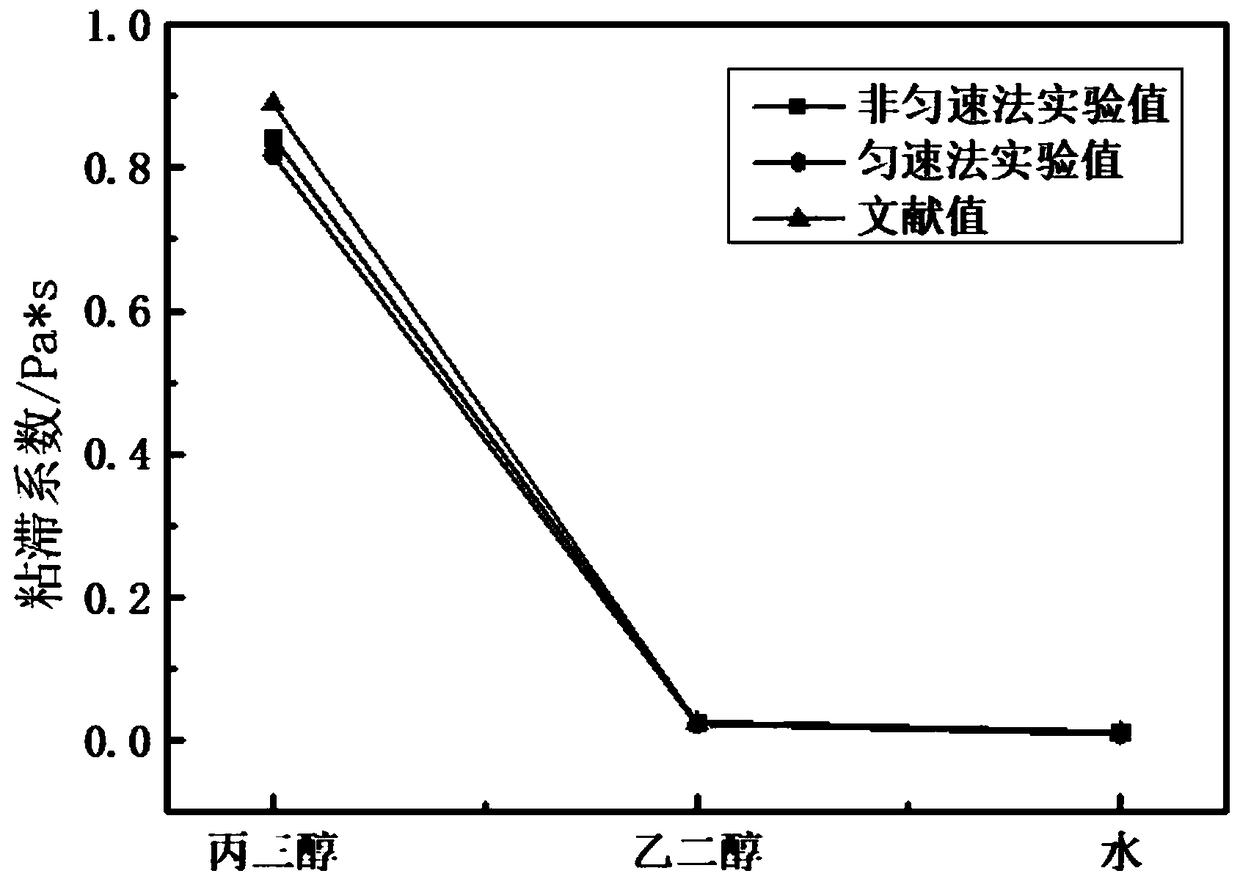

[0060] Embodiment 3: Measurement of different liquid viscosity coefficients.

[0061] The measuring device in Example 2 is used to measure the viscosity coefficients of water, ethylene glycol and glycerin three different liquids. The inner diameter of the vertical drop tube 4 used is 50mm. The falling balls used were silicon nitride balls with a diameter of 2.98 mm (density 3.2 kg / m3).

[0062] At the same temperature, pour water, ethylene glycol, and glycerin into the vertical drop tube respectively, and keep the temperature of the liquid to be tested at 25°C by adjusting the circulating heating water pump knob; the resolution of the camera used is 1920X1080 Pixel USB camera that shoots at 30 frames per second.

[0063] Use video recording software to record the silicon nitride ball falling from the liquid surface to be tested until the falling ball touches the bottom. After the video recording is over, use video editing software, such as Adobe Premiere, to read the fallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com