A Measuring Device for Flight Process Parameters of Multiple Types of Fuzes

A technology for parameter measurement and flight process, applied in fuzes, offensive equipment, weapon accessories, etc., can solve the problems of insufficient storage depth, single recorded data, large size, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

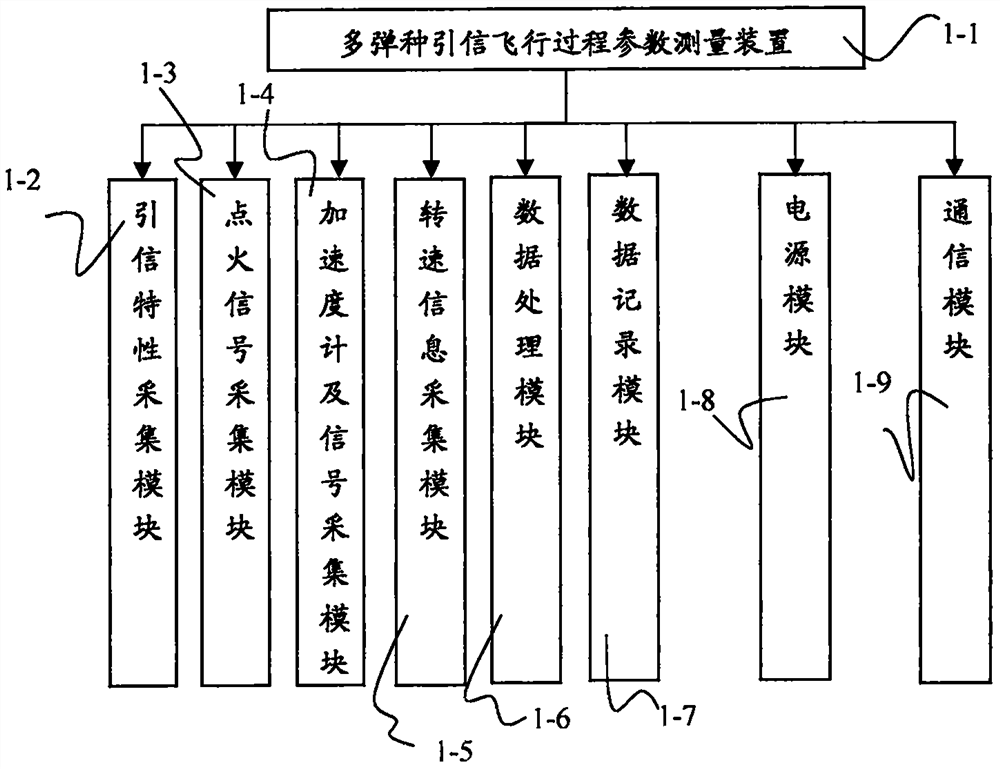

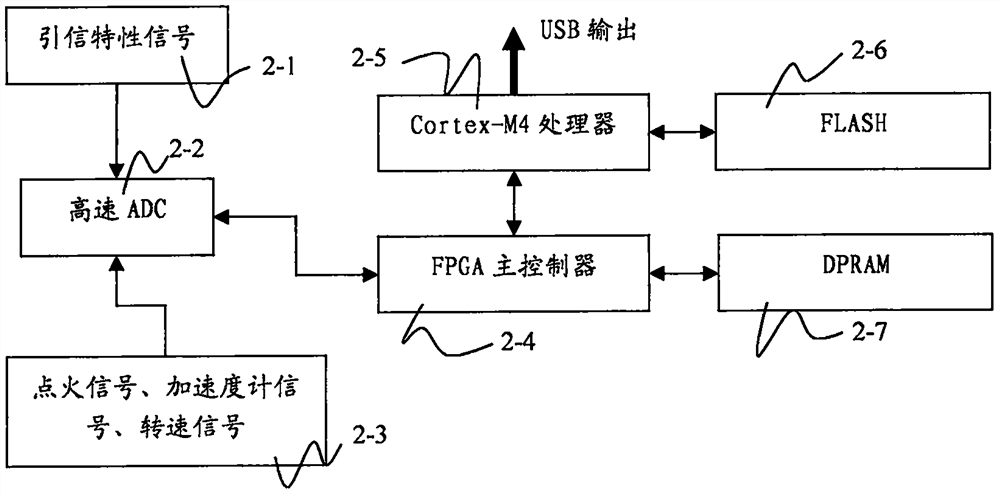

[0024] The multi-bomb fuze flight process parameter measuring device (1-1) proposed by the present invention mainly uses a fuze characteristic acquisition module (1-2), an ignition signal acquisition module (1-3), an accelerometer and a signal acquisition module (1-4 ), the rotational speed information acquisition module (1-5) to obtain the characteristic parameters of the fuze in the working process, and the environmental force information of the projectile during the flight; the data processing module (1-6) is responsible for corresponding data processing, and realizes electric The conversion of the characteristic signal to the environmental force signal; the data recording module (1-7) receives the information of the data processing module and stores it at high speed; the power supply module (1-8) is responsible for the power supply of the fuze environmental force measuring device; the communication module (1-9 ) is used for external data transmission of the device and accep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com