High-temperature-resistant elastic well cementing cement paste system applied to thickened oil thermal production well and preparation method of high-temperature-resistant elastic well cementing cement paste system

A technology of oil well cement and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no mention of cement stone elasticity, inability to guarantee elasticity, and strength decline, so as to ensure long-term integrity, Good compressive strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

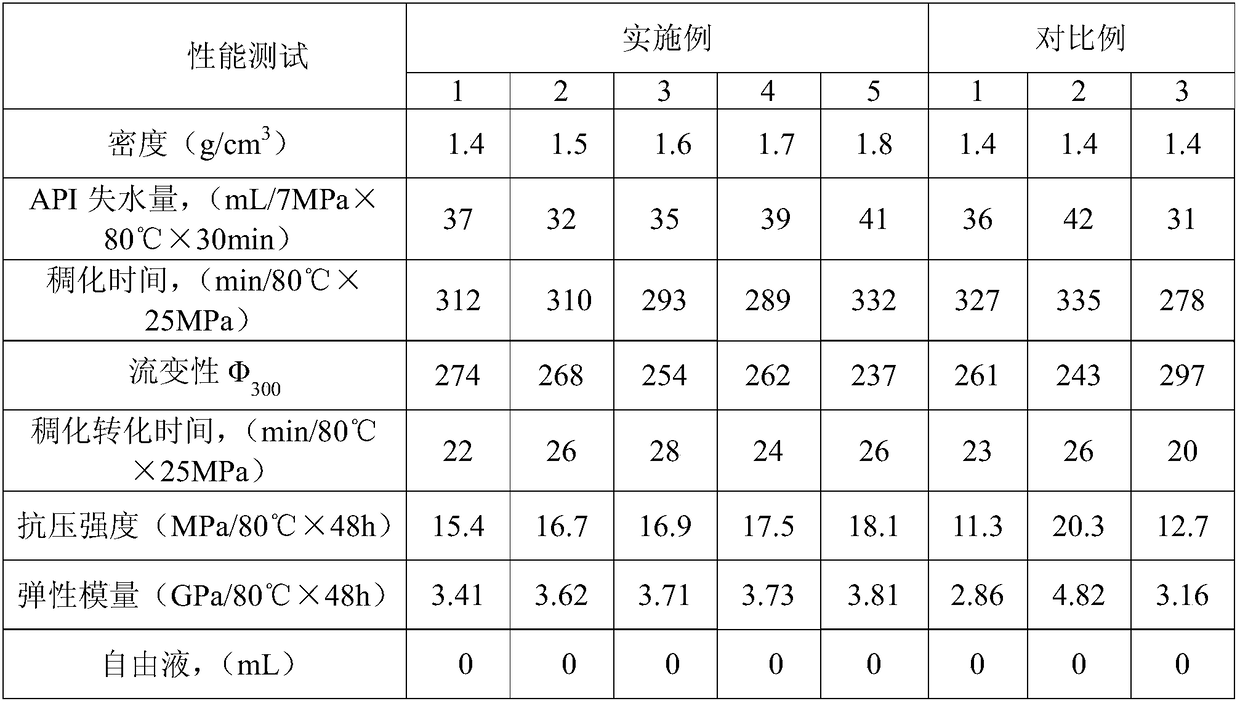

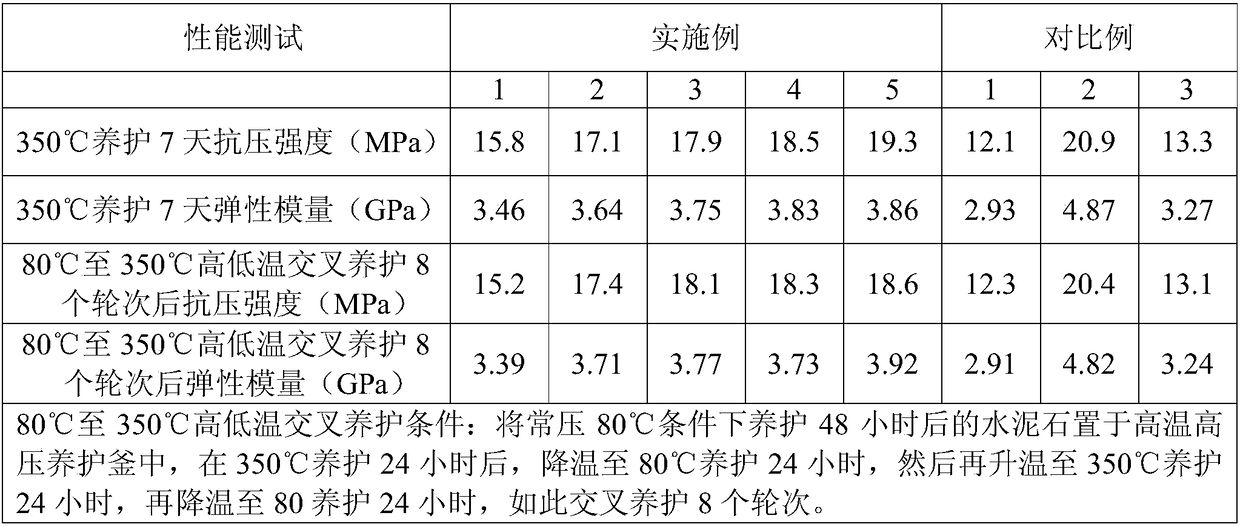

Embodiment 1

[0043] Embodiment 1, preparation of high temperature resistant elastic cement slurry for thermal recovery well cementing

[0044]The high temperature resistant elastic well cementing cement slurry system for heavy oil thermal recovery wells according to the present invention has a density of 1.40g / cm 3 The cement slurry, the preparation method comprises the following steps successively: (1) take by weighing 100 weight parts of oil well cement (oil well G grade cement), 26 weight parts of lightening agent (hollow glass microspheres, true density is 0.4g / cm 3 , the particle size range is 20-100 μm), 35 parts by weight of high-temperature stabilizer (silica sand powder, the particle size range is 45 μm-75 μm, and the density is 2.65 g / cm 3 , the silicon dioxide content is 99.0%), 0.3 parts by weight of high temperature resistant fiber (carbon fiber, the length is 3mm), 4 parts by weight of high temperature resistant inorganic toughening agent (acicular wollastonite, particle size...

Embodiment 2

[0051] Embodiment 2, preparation of high temperature resistant elastic cement slurry for thermal recovery well cementing

[0052] The high temperature resistant elastic well cementing cement slurry system for heavy oil thermal recovery wells according to the present invention has a density of 1.50g / cm 3 The cement slurry preparation method comprises the following steps successively: (1) take by weight the oil well cement (oil well G grade cement) of 100 weight parts, the lightening agent (hollow glass microspheres) of 18 weight parts, true density is 0.4g / cm 3 , the particle size range is 20-100 μm), 35 parts by weight of high-temperature stabilizer (silica sand powder, the particle size range is 45 μm-75 μm, and the density is 2.65 g / cm 3 , the silica content is 99.0%), 0.3 parts by weight of high temperature resistant fiber (carbon fiber, length is 3mm), 5 parts by weight of high temperature resistant inorganic toughening agent (acicular wollastonite, particle size 30 μm ~ 5...

Embodiment 3

[0053] Embodiment 3, preparation of high temperature resistant elastic cement slurry for thermal well cementing

[0054] The high temperature resistant elastic well cementing cement slurry system for heavy oil thermal recovery wells according to the present invention has a density of 1.60g / cm 3 The cement slurry preparation method comprises the following steps successively: (1) take by weight the oil well cement (oil well G grade cement) of 100 weight parts, the lightening agent (hollow glass microspheres) of 10 weight parts, true density is 0.4g / cm 3 , the particle size range is 20-100 μm), 35 parts by weight of high-temperature stabilizer (silica sand powder, the particle size range is 45 μm-75 μm, and the density is 2.65 g / cm 3 , the silica content is 99.0%), 0.3 parts by weight of high temperature resistant fiber (carbon fiber, length is 3mm), 5 parts by weight of high temperature resistant inorganic toughening agent (acicular wollastonite, particle size 30 μm ~ 50 μm), 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com