Method and a device for dynamically detecting defects of ballastless track

A ballastless track and dynamic detection technology, which is applied in transportation and packaging, railway vehicle shape measuring devices, railway car body parts, etc., can solve the problems of high detection and maintenance costs, deviation of electromagnetic wave technology detection results, and large cost of manpower and material resources. Achieve the effects of improved detection and maintenance work efficiency, significant progress and application value, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

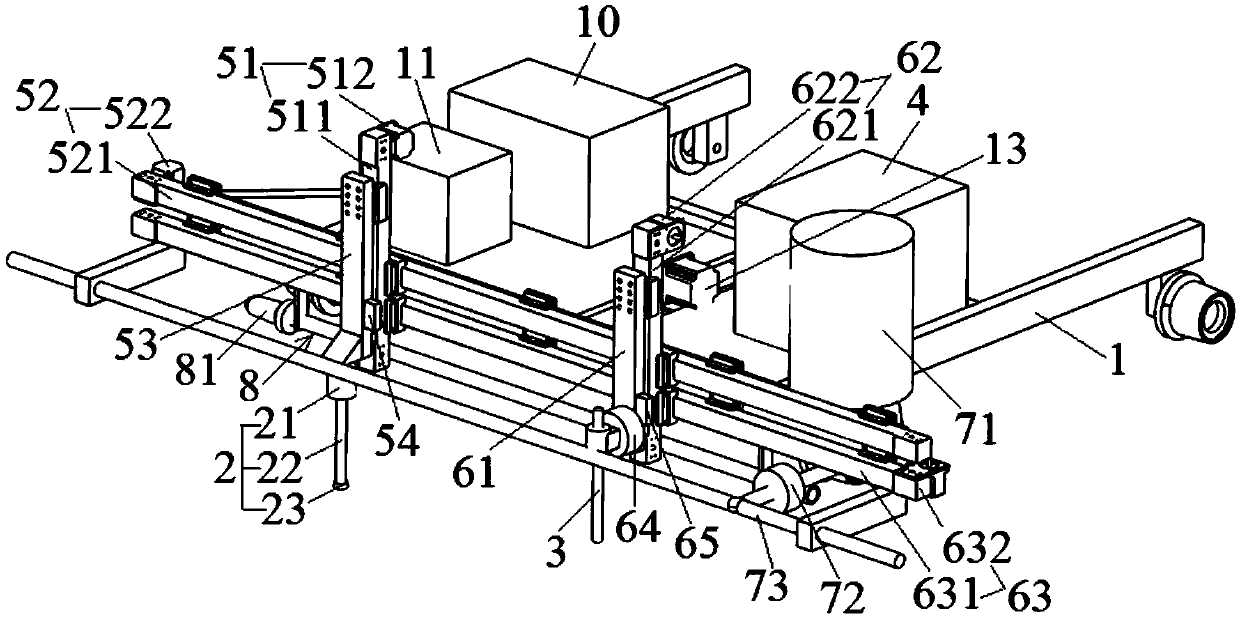

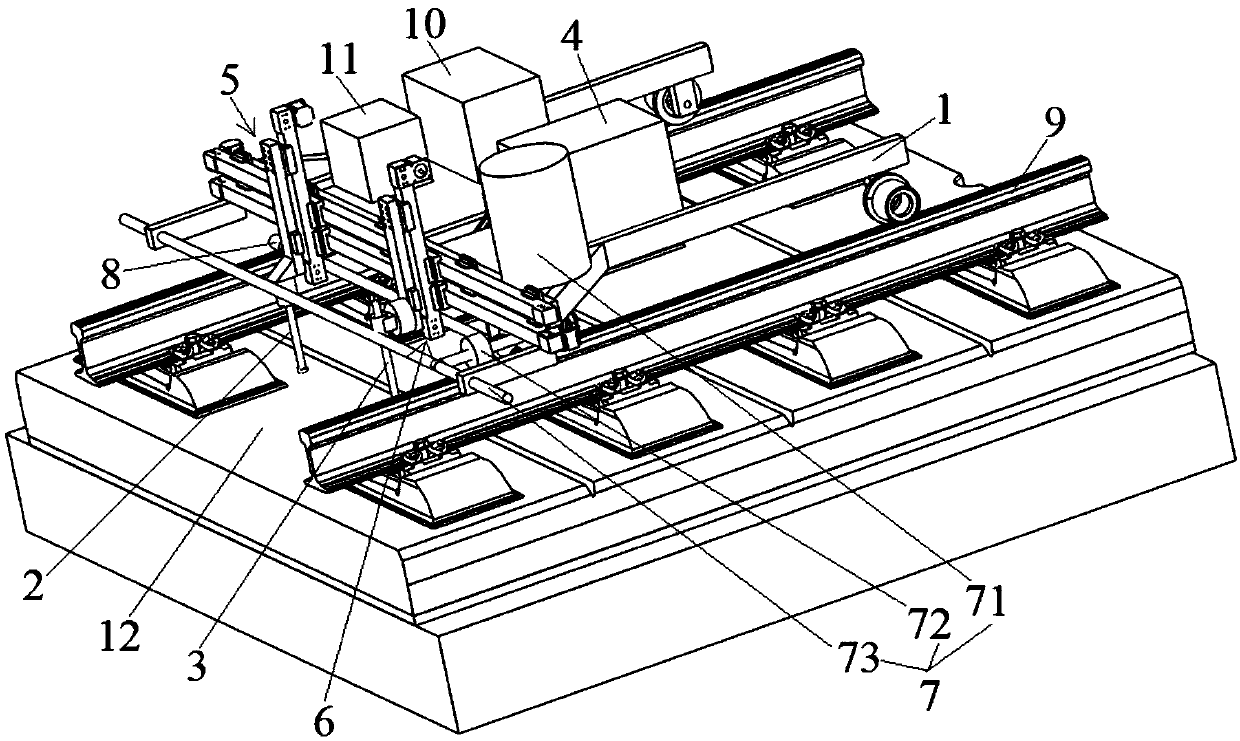

[0027] see figure 1 and figure 2 As shown: a device for dynamic detection of ballastless track defects provided by this embodiment, including a track inspection trolley 1, a sound wave excitation unit 2, a microphone sensor 3 and a computer 4, the sound wave excitation unit 2 and a two-axis displacement adjustment mechanism 5 The microphone sensor 3 is connected with an adaptive displacement feedback adjustment device 6 , and the biaxial displacement adjustment mechanism 5 and the adaptive displacement feedback adjustment device 6 are both fixedly connected to the front end of the track inspection trolley 1 .

[0028] In this example:

[0029] The acoustic wave excitation unit 2 includes a vibrator 21 and a vibrating rod 22, the top of the vibrating rod 22 is fixedly connected to the output end of the vibrator 21, and a pressure is fixed at the bottom end of the vibrating rod 22. sensor 23.

[0030] The biaxial displacement adjustment mechanism 5 includes a longitudinal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com