Miniaturized anti-high overload linear polarization single helical antenna

A single-spiral, linearly polarized technology, applied in the directions of the antenna support/installation device, the structural connection of the antenna grounding switch, the structural form of the radiating element, etc. Resistance increases and other problems, to achieve the effect of taking into account the requirements of mechanical and electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the structure and features of the present invention in detail, the following preferred embodiments are given and described below with accompanying drawings.

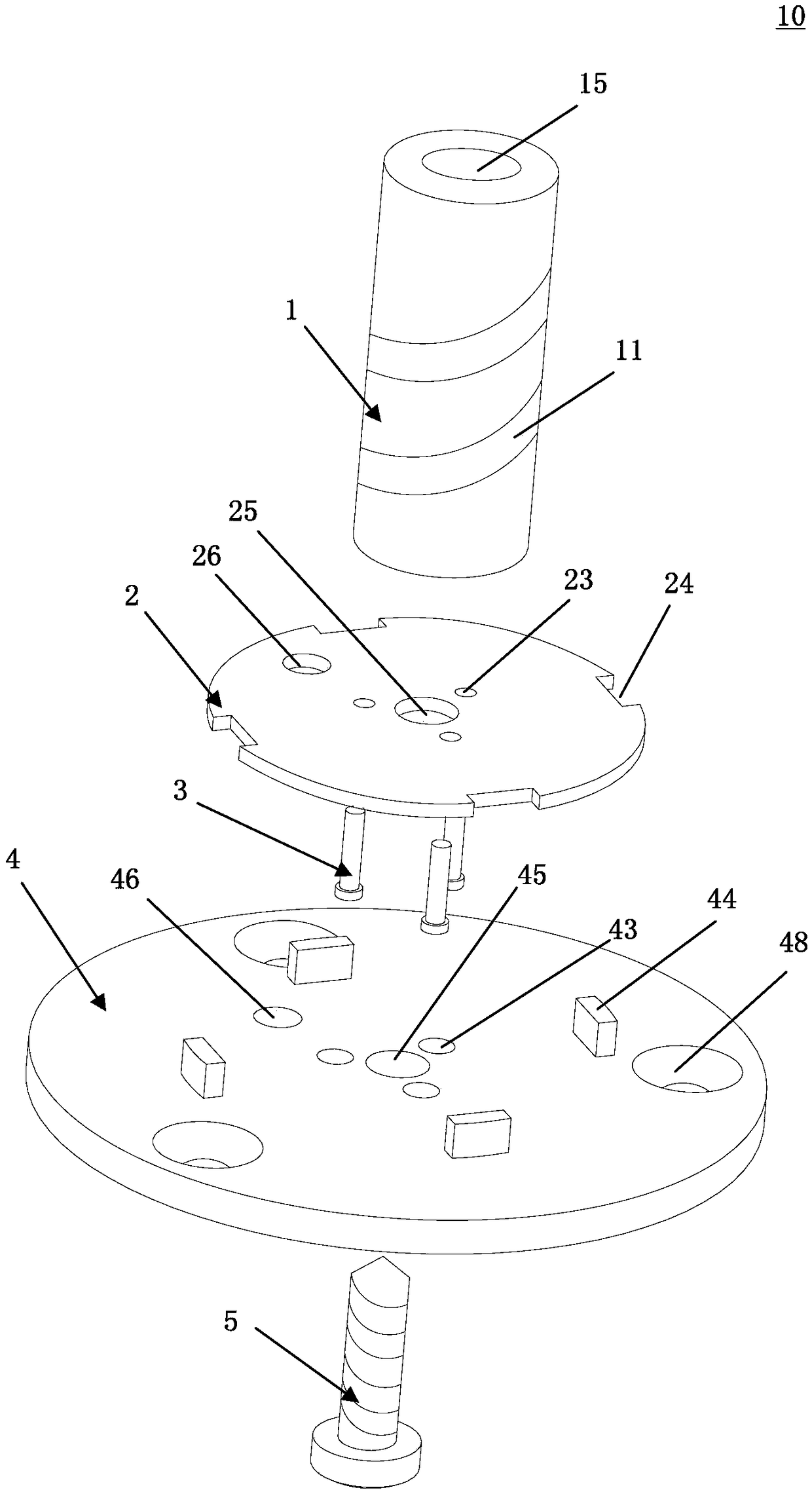

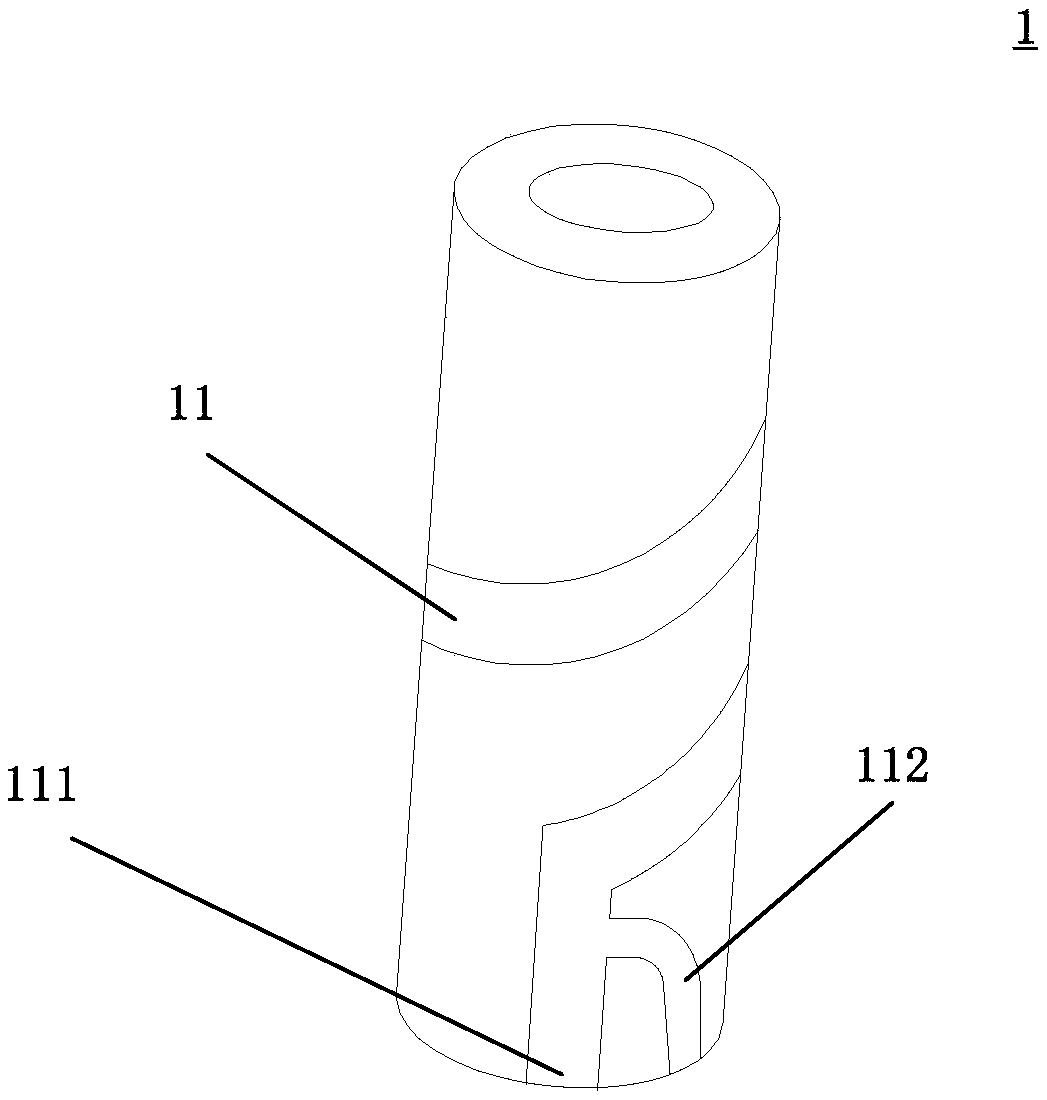

[0016] see Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the combined three-dimensional structure of the miniaturized anti-high overload linearly polarized single helical antenna of the present invention. figure 2 It is a schematic diagram of the decomposed three-dimensional structure of the miniaturized anti-high overload linearly polarized single helical antenna of the present invention. image 3 It is a structural representation of a deformation design of the antenna post in the miniaturized anti-high overload linearly polarized single helical antenna of the present invention. The present invention proposes a miniaturized anti-high overload linearly polarized single helical antenna 10 , which includes: antenna post 1 , low noise amplifier circuit board 2 , anti-rotation n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com