A three-dimensional porous lithium metal composite anode material, preparation method and application thereof

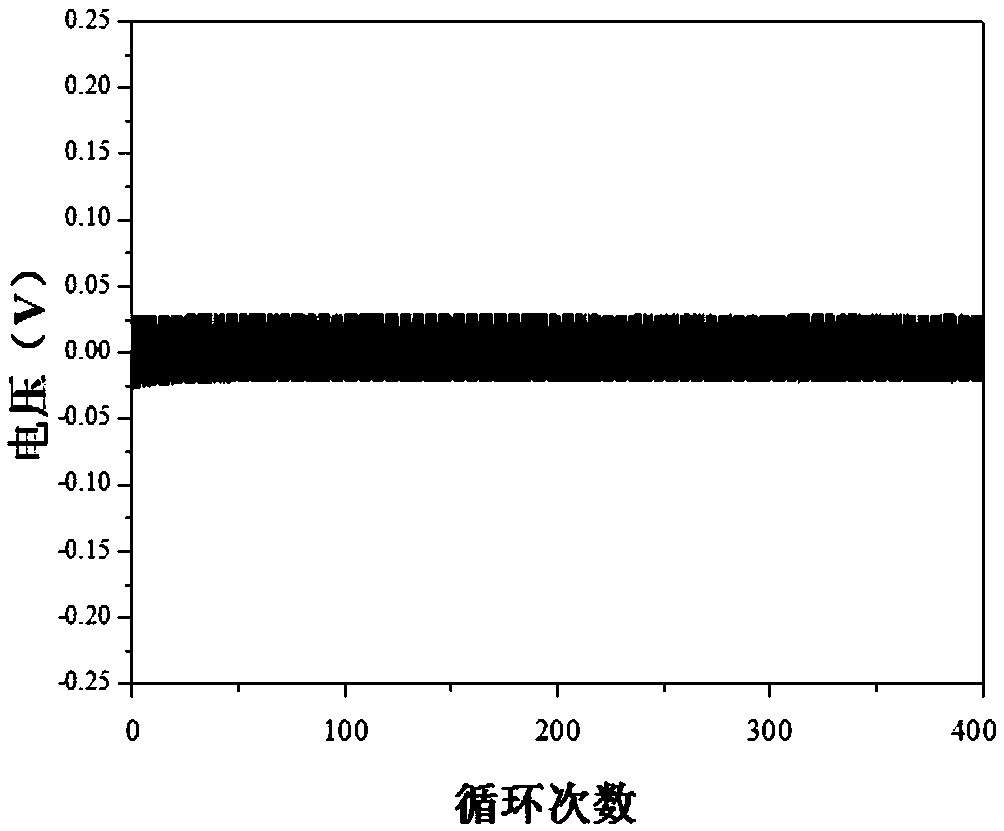

A technology of three-dimensional porous and negative electrode materials, applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the difficulties of automation and large-scale industrialization, high manufacturing costs of three-dimensional porous current collector materials, and unsatisfactory Coulombic efficiency and other issues, to achieve the effect of increasing cycle stability and Coulombic efficiency, reducing current density, good electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) The 1000-mesh 304 stainless steel mesh (wire diameter 0.04mm, thickness 0.14mm) was punched under the cutting machine to obtain a current collector disc with a diameter of 12mm. It is pretreated: first use dilute hydrochloric acid with a mass fraction of 5% to carry out pickling treatment at 25° C., and the pickling time is 10 minutes. Then use alcohol and ultrasonic vibration to clean 3 times, 15 minutes each time, to clean the oxides and oil stains on the surface, and finally dry the stainless steel mesh in a vacuum oven at 80°C for 5 hours with a vacuum degree of 1000Pa.

[0046] (2) Place the stainless steel mesh cleaned and dried in step (1) in a glow ion nitriding furnace for surface nitrogen doping treatment. The surface nitrogen doping treatment temperature is 500°C, the time is 1 hour, the gas source is ammonia gas, and the air pressure is 300Pa; the surface scanning electron microscope image of the obtained nitrogen-doped stainless steel mesh collector flu...

Embodiment 2

[0050] (1) The 1000-mesh 316 stainless steel mesh (wire diameter 0.05 mm, thickness 0.15 mm) was punched under a cutting machine to obtain a current collector disc with a diameter of 12 mm. It is pretreated: first use dilute hydrochloric acid with a mass fraction of 3% to carry out pickling treatment at 30° C., and the pickling time is 8 minutes. Then use alcohol supplemented with ultrasonic vibration to clean 3 times, each cleaning time is 10 minutes, and finally the stainless steel mesh is dried in a vacuum drying oven at 60°C for 8 hours, and the vacuum degree is 2000Pa.

[0051] (2) Place the stainless steel mesh cleaned and dried in step (1) in a glow ion nitriding furnace for surface nitrogen doping treatment. The treatment temperature is 300°C, the time is 0.1 hour, the gas source is ammonia gas, and the air pressure is 250Pa;

[0052] (3) Stack the nitrogen-doped stainless steel sheet and the lithium sheet obtained in step (2) into a tablet press, gradually increase t...

Embodiment 3

[0055] (1) The 500-mesh 304 stainless steel mesh (wire diameter 0.03 mm, thickness 0.05 mm) was punched under a cutting machine to obtain a current collector disc with a diameter of 12 mm. It is pretreated: first use dilute hydrochloric acid with a mass fraction of 2.5% to carry out pickling treatment at 45° C., and the pickling time is 20 minutes. Then use alcohol and ultrasonic vibration to clean 3 times, each time for 15 minutes, to clean the oxide and oil on the surface, and finally dry the stainless steel mesh in a vacuum drying oven at 60°C for 8 hours, with a vacuum degree of 3500Pa;

[0056] (2) Place the stainless steel mesh cleaned and dried in step (1) in a glow ion nitriding furnace for surface nitrogen doping treatment. Nitriding treatment temperature is 350 DEG C, time is 0.1 hour, and the gas source charged is ammonia gas, and the air pressure is 300Pa; The 500 mesh stainless steel mesh used in this embodiment is different from the 1000 mesh stainless steel mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com