A dynamic design method of high speed machining machine tool structure considering the stiffness of joint

A technology for processing machine tools and complete machine structures, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of theoretical calculation of angular stiffness, inability to meet the dynamic design of high-speed processing machine tools, lack of dynamic parameter theoretical models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

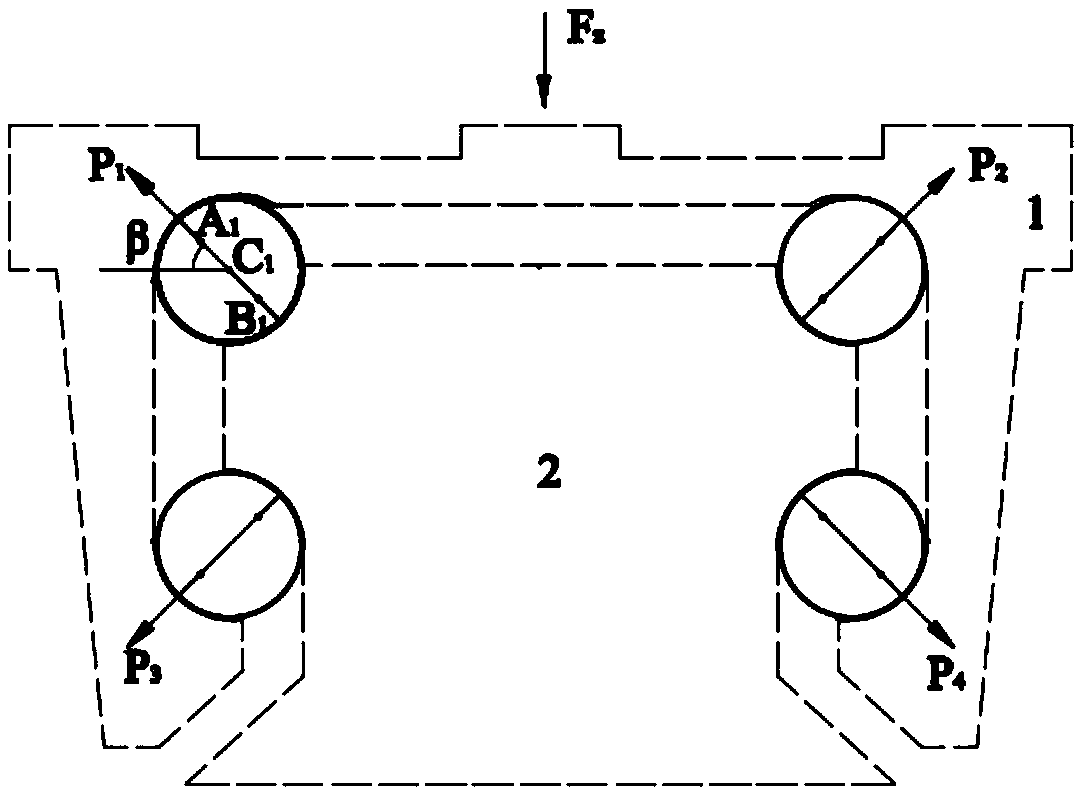

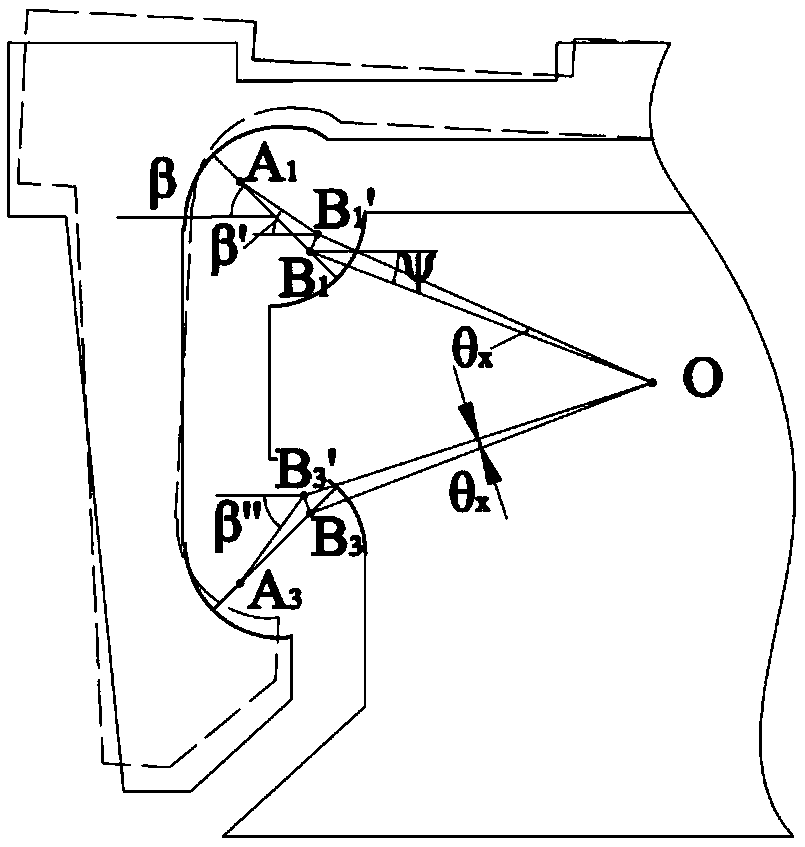

[0105] In the following, an embodiment (high-speed precision internal-circle compound grinding machine) will be used to further describe the dynamic design method of the high-speed machining machine in consideration of joint stiffness coupling in the present invention.

[0106] Figure 7 The specific content of the high-speed machining machine tool structure dynamic design method considering the joint stiffness of the present invention is given, including the following steps:

[0107] Step 1: 3D digital modeling of high-speed machining tools

[0108] Use 3D modeling software (such as Solidworks) to establish a 3D digital (CAD, CAE) model of a high-speed precision internal cylindrical compound grinding machine, such as Figure 8 shown.

[0109] Step 2: Analysis of dynamic parameters of the plane joint of the machine tool

[0110] Step 2a: Using formula (1), calculate the normal stiffness K of the plane junction n

[0111] Step 2b: Using formula (2), calculate the tangentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com