Control system and method for laser radar galvanometer servo motor

A servo motor and control system technology, applied in general control systems, control/adjustment systems, computer control, etc., can solve the problems of no advantages in speed and precision indicators, complex neural network control, and low speed indicators, etc., and reach the target area range The effect of wide, fast response and large scanning angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

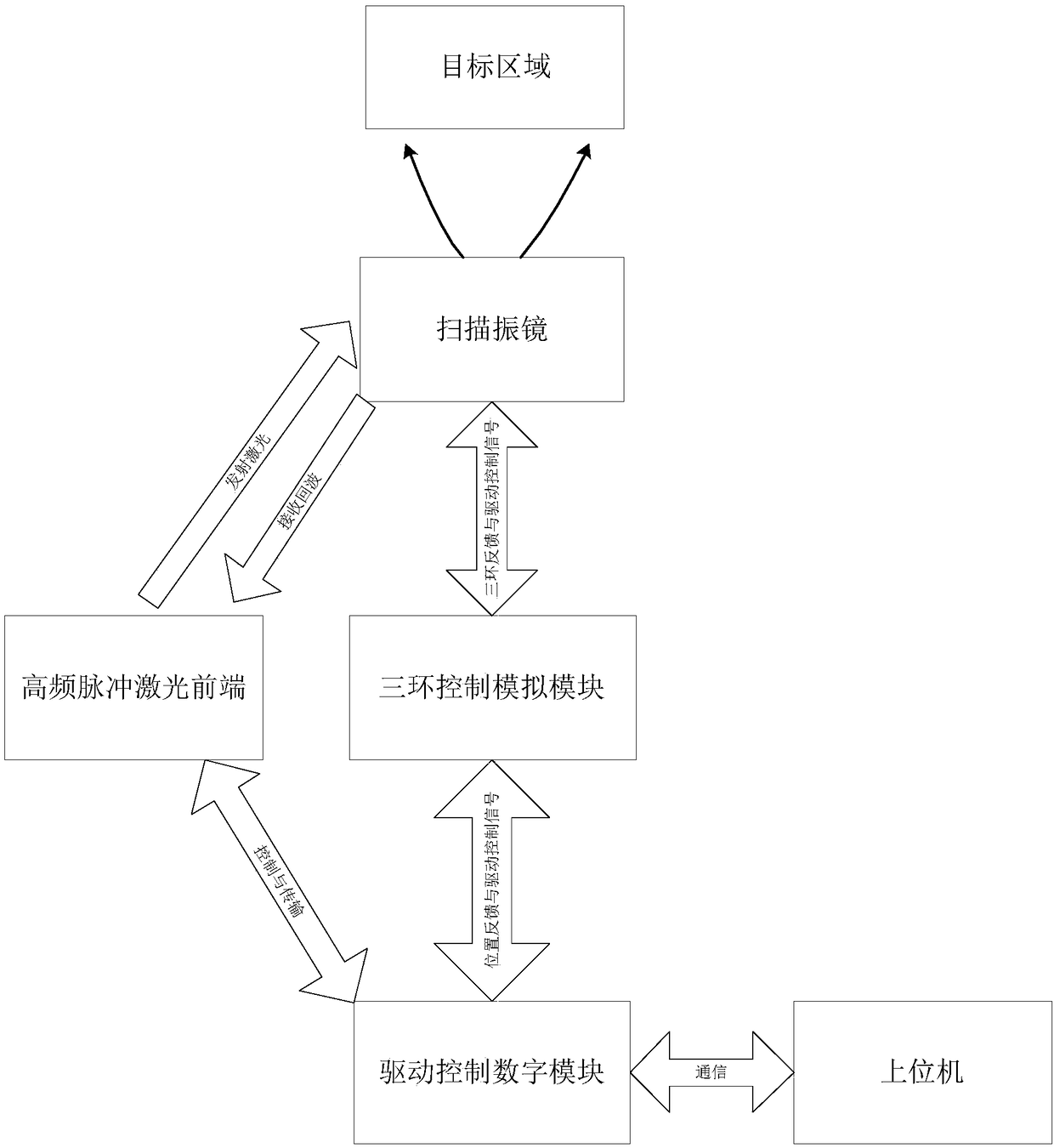

[0062] This embodiment is aimed at the control system of the laser radar galvanometer servo motor, including:

[0063] 1) Select the high-frequency pulse laser front end to generate high-frequency laser, and use a high-sensitivity detector to receive the laser ranging echo;

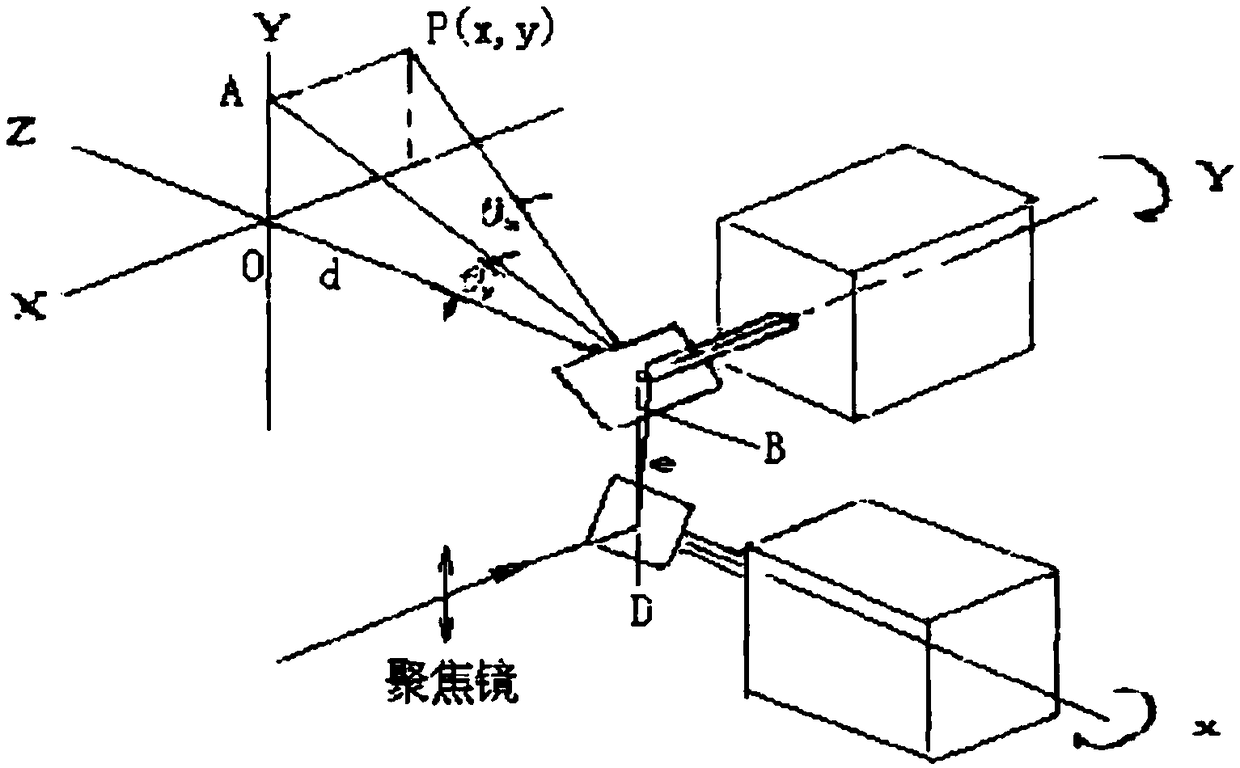

[0064] 2) Use the scanning galvanometer to change the laser light path, and periodically scan the designated area;

[0065] 3) Send the obtained laser beam position and target distance information to the host computer through the drive control digital module;

[0066] 4) The host computer draws the point cloud image of the designated area through the 3D reconstruction software.

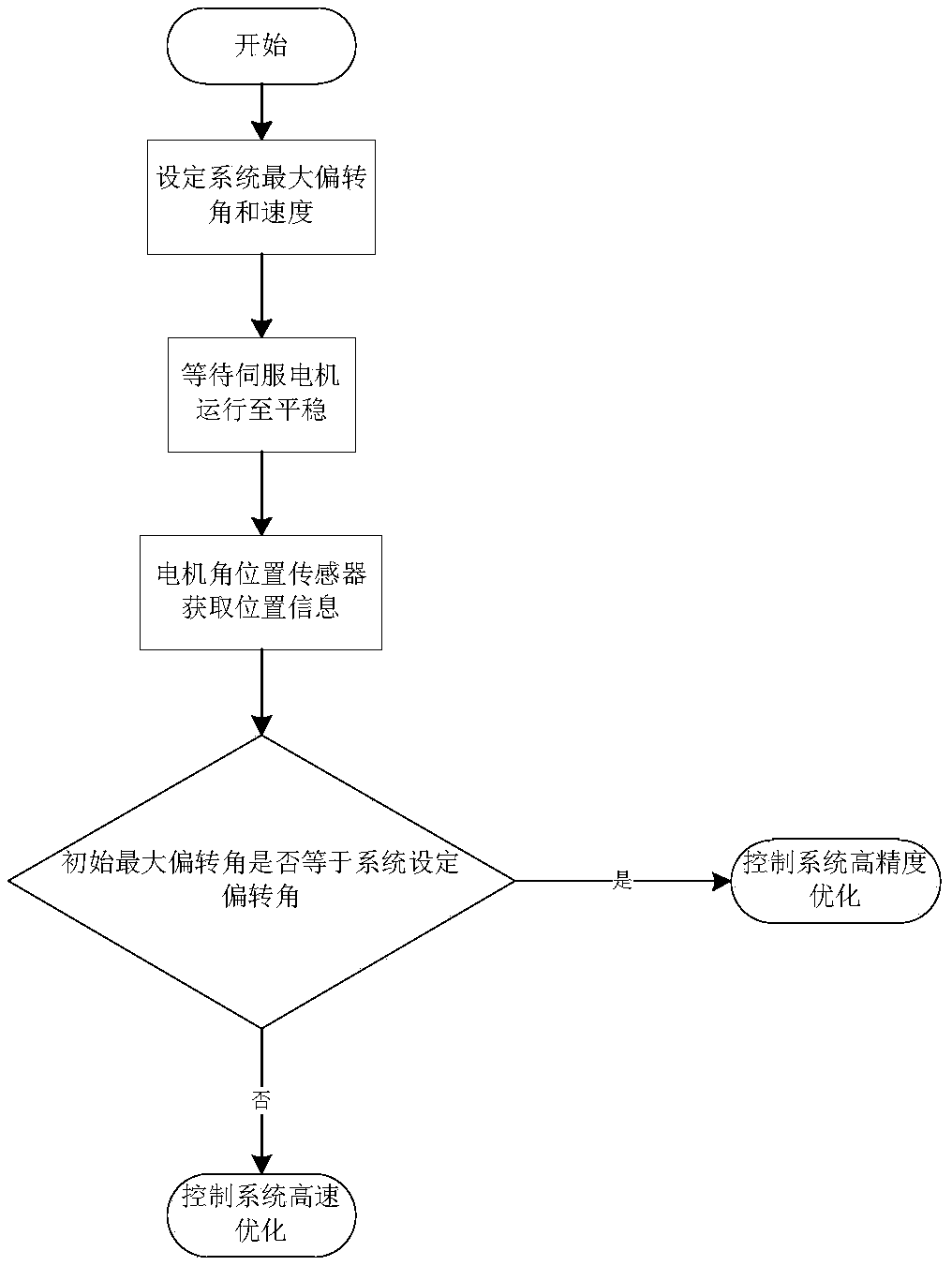

[0067] The servo drive control system is composed of a drive control digital module and a three-loop control analog module, and the drive control digital module is composed of ARM and FPGA. The drive control digital module has the functions of generating drive signals, processing feedback signals, judging system status, and sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com