Scanning mirror and scanning method thereof

A technology for scanning mirrors and mirrors, which is applied in the field of mirrors, can solve the problems of high cost, complex structure, difficulty in meeting the scanning frequency, etc., and achieve the effect of large scanning angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

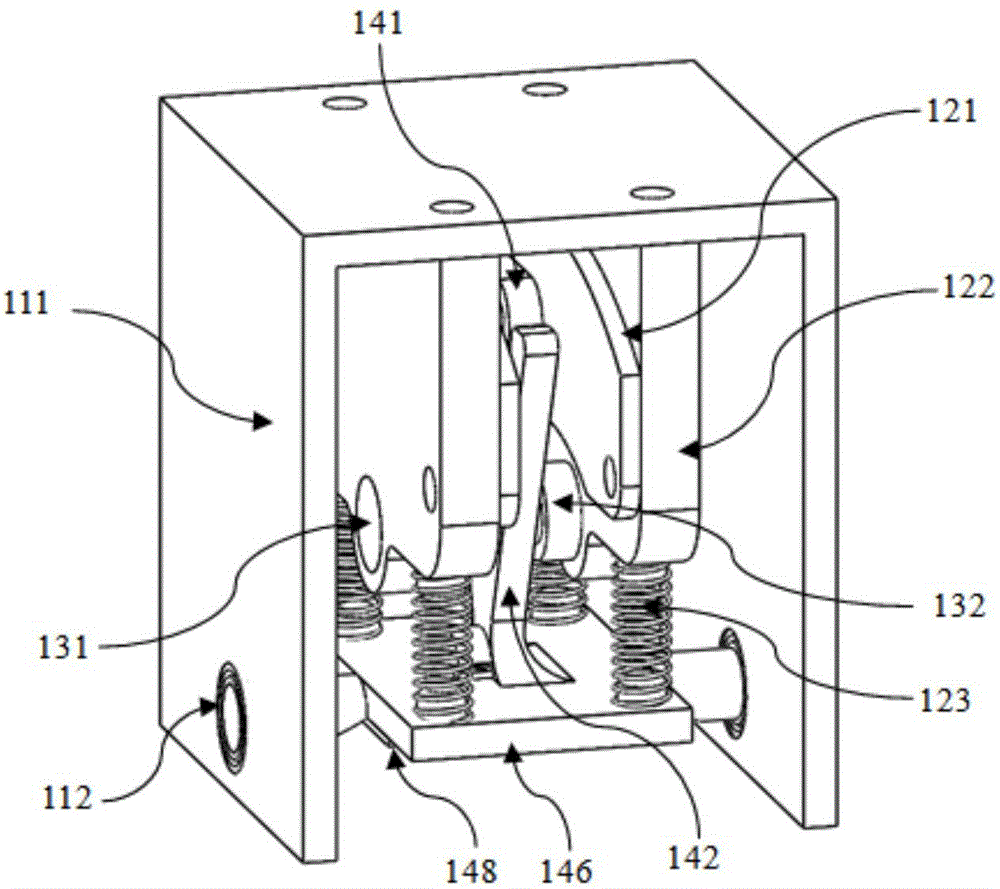

[0043] see Figure 1-2 . As shown in the figure, the present invention discloses a scanning mirror, including a laser reflection module 140 and a laser feedback module 130; the laser reflection module 140 is used to reflect laser light; Feedback compensation of amplitude and frequency enables the scanning mirror to work at a fixed scanning amplitude and a fixed frequency.

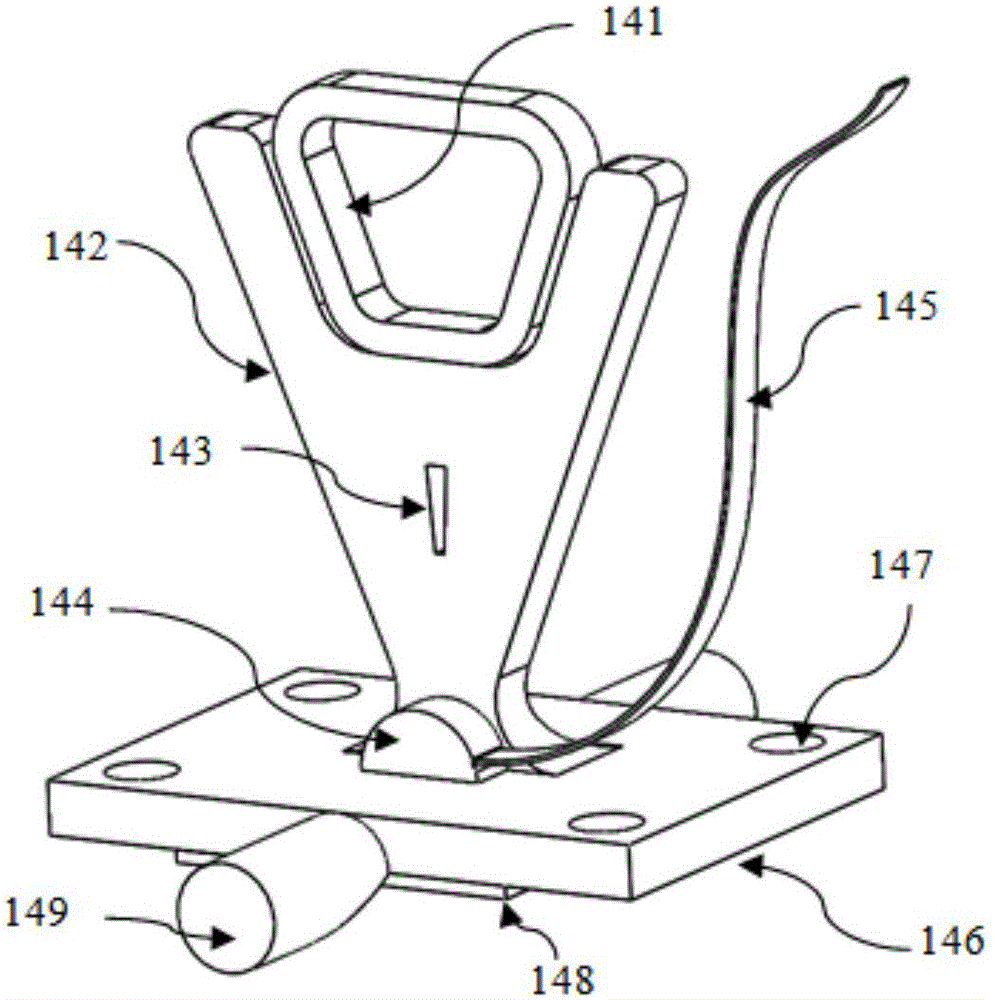

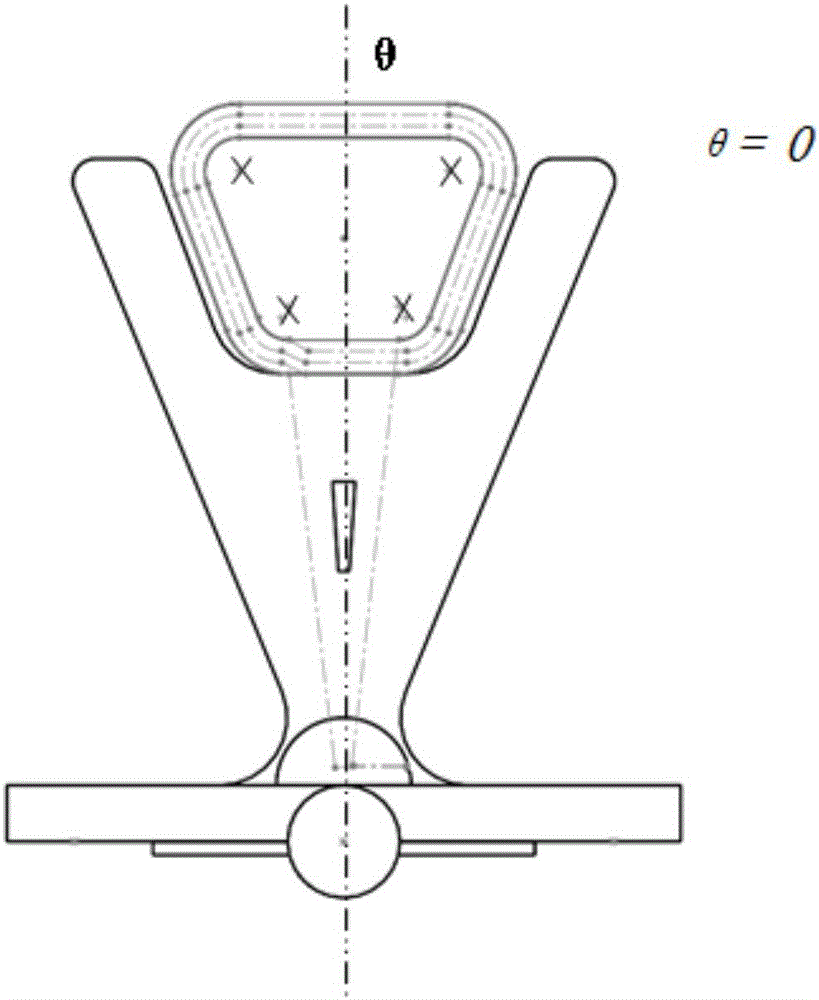

[0044] The laser reflection module 140 includes a coil 141, a base 146, a rotating shaft 149 and a mirror 148. The coil 141 is fixed on the upper surface of the base 146 through a coil bracket 142, and the mirror 148 is bonded to the The lower surface of the base 146, the lens thickness of the reflector 148 is 1mm, the mirror surface of the reflector 148 is rectangular, and the mirror surface size is 10mm * 10mm; the two sides of the base 146 are provided with a rotating shaft 149, The rotation axis 149 is perpendicular to the plane where the coil 141 is located, and the reflector 148 deflects around the ...

Embodiment 2

[0066] The invention discloses a scanning mirror, which includes a laser reflection module 140 and a laser feedback module 130; the laser reflection module 140 is used to reflect infrared laser; the laser feedback module 130 controls the amplitude and frequency of the scanning mirror Feedback compensation enables the scanning mirror to work at a fixed scanning amplitude and a fixed frequency.

[0067] The laser reflection module 140 includes a coil 141, a base 146, a rotating shaft 149 and a mirror 148. The coil 141 is fixed on the upper surface of the base 146 through a coil bracket 142, and the mirror 148 is bonded to the The lower surface of the base 146, the lens thickness of the reflector 148 is 1mm, the mirror surface of the reflector 148 is circular, and the mirror diameter is 10mm; The rotation axis 149 is perpendicular to the plane where the coil 141 is located, and the reflector 148 deflects around the rotation axis 149 when the coil 141 is energized.

[0068] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com