Tight reservoir compressibility evaluation method for determining fractured rock crack areas

A technique for tight reservoir and evaluation method, applied in the field of tight reservoir fracturing, can solve problems such as the inability to truly reflect the compressibility of reservoir rocks, and achieve the effect of simple, easy and universal applicability of the method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described further below:

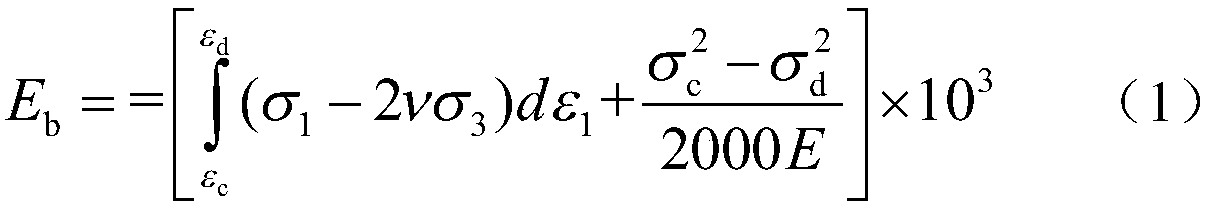

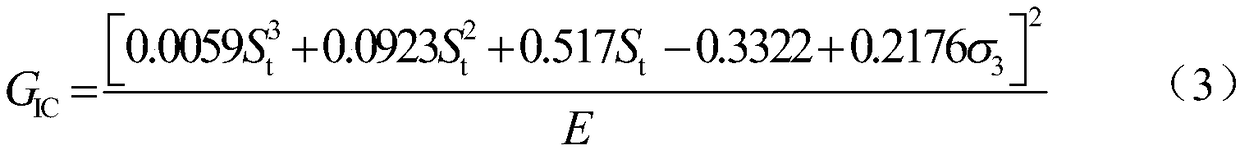

[0031] This tight reservoir compressibility evaluation method for determining the area of fractured rock fractures includes the following steps:

[0032] Step 1. Select a block of rock to prepare a dense rock sample of φ25mm×50mm. The two ends of the dense rock sample are required to be parallel to each other. The error of the height of the test piece shall not be greater than 0.3mm, the end face of the tight rock sample shall be perpendicular to the axis of the tight rock sample, and the maximum deviation of the end face of the tight rock sample shall not be greater than 0.25°.

[0033] Step 2: Use a triaxial compression testing machine to perform a triaxial compression test on the compact rock sample, first increase the confining pressure to a predetermined value σ at a constant rate 3 , and then axially loaded until failure, to obtain the axial stress-strain curve and the corresponding radial strain.

[0034] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com