Micro-quantitative sampling system for biochip

A quantitative sampling and biochip technology, applied in sampling devices and other directions, can solve the problems of longer sample time, easy clogging of filter membranes, and crushed red blood cells, and achieves simple structure, sufficient blood filtration, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

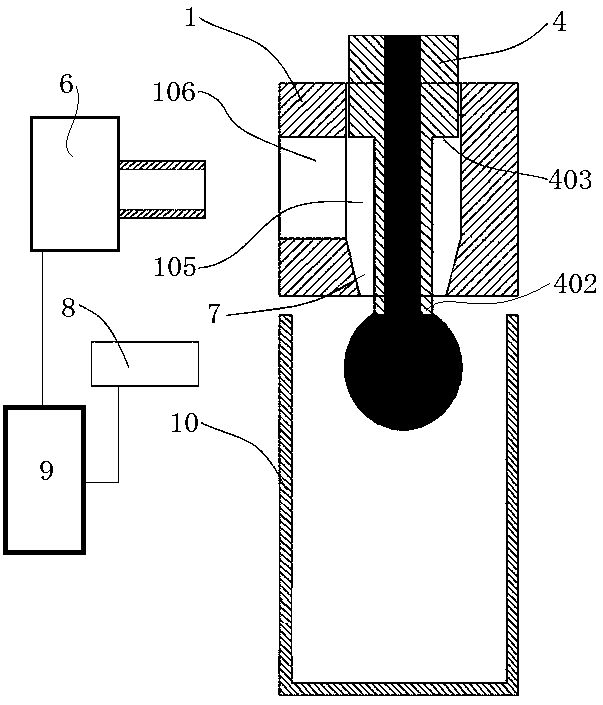

[0037] Such as figure 1 As shown, the biochip microquantitative sampling system includes a quantitative tube 4, and the bottom of the quantitative tube 4 offers a sample outlet 402; it also includes a housing 1, an air blowing unit 6, a camera unit 8 and a controller 9, and the housing 1 is provided with an installation through hole 105, the lower section of the quantitative tube 4 extends into the installation through hole 105, and the air blowing hole 106 connecting the air outlet of the blowing unit 6 and the lower section of the quantitative tube 4 is set on the side wall of the housing 1, and the lower section of the quantitative tube 4 and the installation through hole 105 The air passage 7 communicating with the blowing through hole 106 and the outer wall of the sample outlet 402 is formed between them; the sample outlet 402 is located within the field of view of the imaging unit 8, and the imaging unit 8 and the blowing unit 6 are electrically connected to the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com