The control method of the condition control device for the space lateral restraint loading of the test member

A technology of lateral restraint and loading device, which is applied in the field of experimental mechanics, can solve problems such as difficult to accurately reproduce boundary conditions, failure to consider loading system errors, and low accuracy and reliability of test results, so as to reduce adverse effects and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

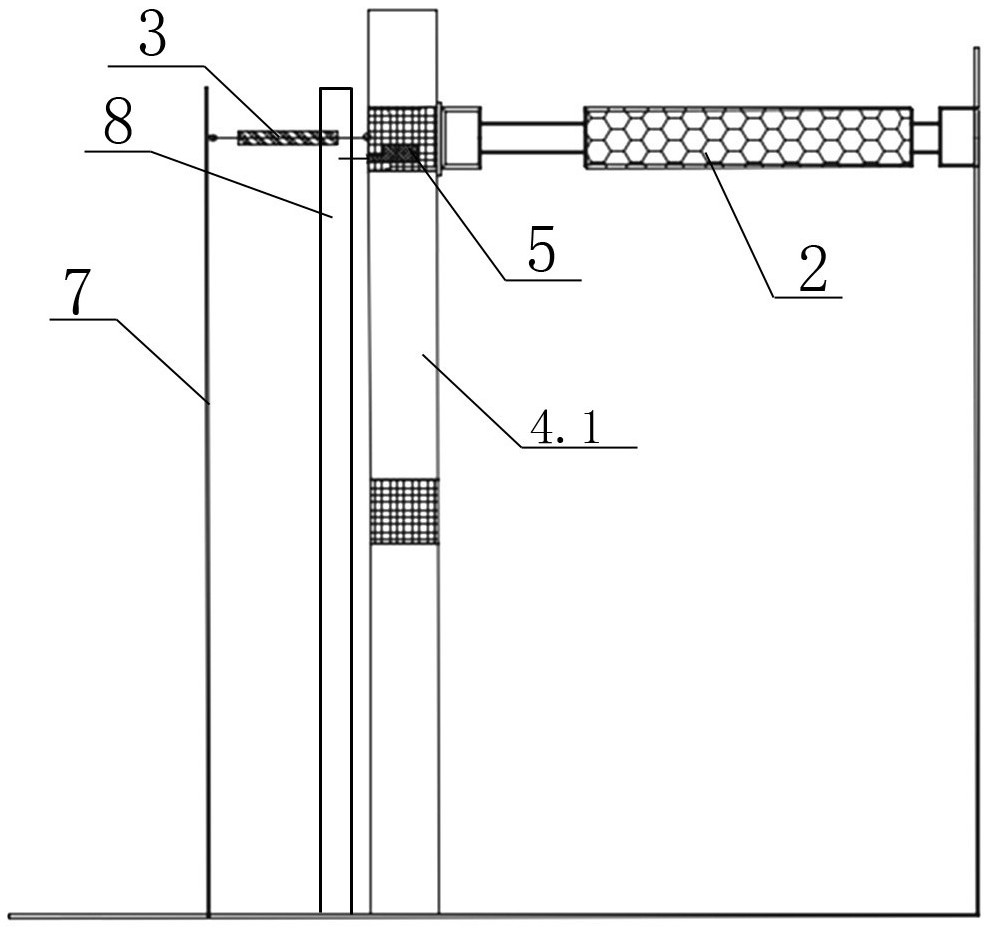

[0034] Such as Figure 1-3As shown, the condition control device for the space lateral restraint loading of the test member includes a loading device 1 and a restraint device 2; the loading device 1 has at least one group, which is arranged on the longitudinal side of the test member 4; wherein, each group The loading devices 1 are vertically arranged in parallel at intervals, and each loading device 1 is set corresponding to the node position of the test member 4; the free end of the loading device 1 is horizontally connected to the test member 4 to apply the main loading direction to the nodes Load; the restraint device 2 has one group, and the free end of the restraint device 2 is horizontally connected to the test member 4 on one lateral side of the test member 4 to constrain the lateral displacement of the node; At each node, on the opposite side of the corresponding constraint device 2, a first displacement measurement device 3 is arranged; the first displacement measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com