Furniture combined connecting buckle

A combined connection and buckle technology, which is applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of inconvenient disassembly and combination, influence on installation, and easy installation errors, etc., so as to improve flexibility and diversification, improve efficiency, reduce The effect of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

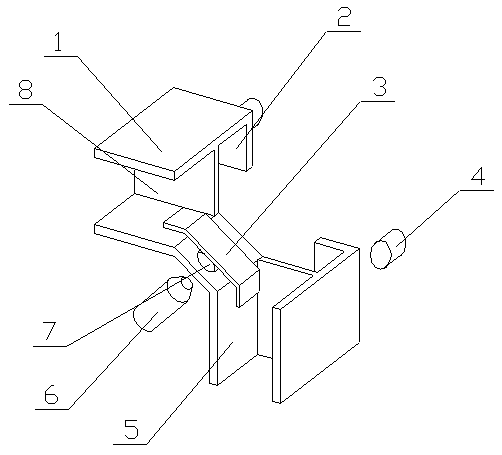

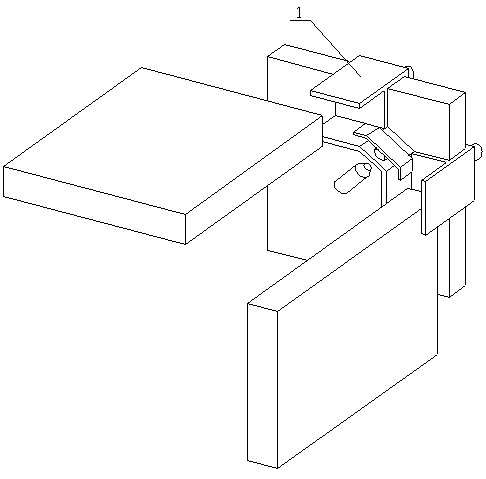

[0032] The combined furniture connection buckle of the present invention is achieved in this way. The combined furniture connection buckle of the present invention includes a corner mounting plate (5), a locking portion and a clamping portion, and the corner mounting plate (5) is composed of The metal plate is bent twice in a row and forms three bending parts. The locking part is placed on the bending part in the middle of the corner mounting plate (5), and the two clamping parts are respectively placed on the corner mounting plate ( 5) On the two outer bending parts;

[0033] The extension lines of the center lines of the two outer bending parts of the corner mounting plate (5) are perpendicular to each other;

[0034] The bending part in the vertical direction of the corner mounting plate (5) is the same length as the bending part in the horizontal direction, and is twice the length of the middle bending part, which can increase the supporting surface for the plate. Less sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com