A screw motor and downhole power drilling tool

A screw motor and bushing technology, which is applied in the driving device for drilling in the borehole, earthwork drilling, drilling equipment, etc., can solve the problem of uneven stress on the stator bushing, early failure of the stator bushing, and glue loss of the stator bushing and other problems, to achieve the effect of avoiding heat accumulation effect, good heat dissipation effect, and avoiding bushing delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the invention are further described below with reference to the accompanying drawings and through specific embodiments.

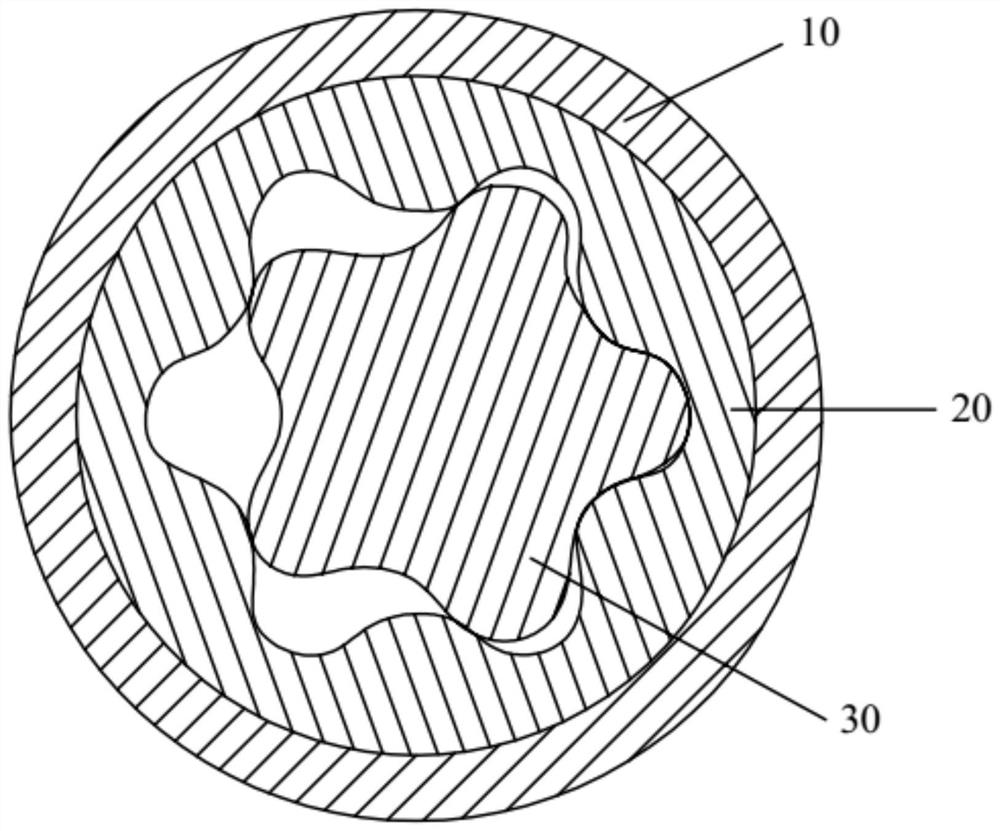

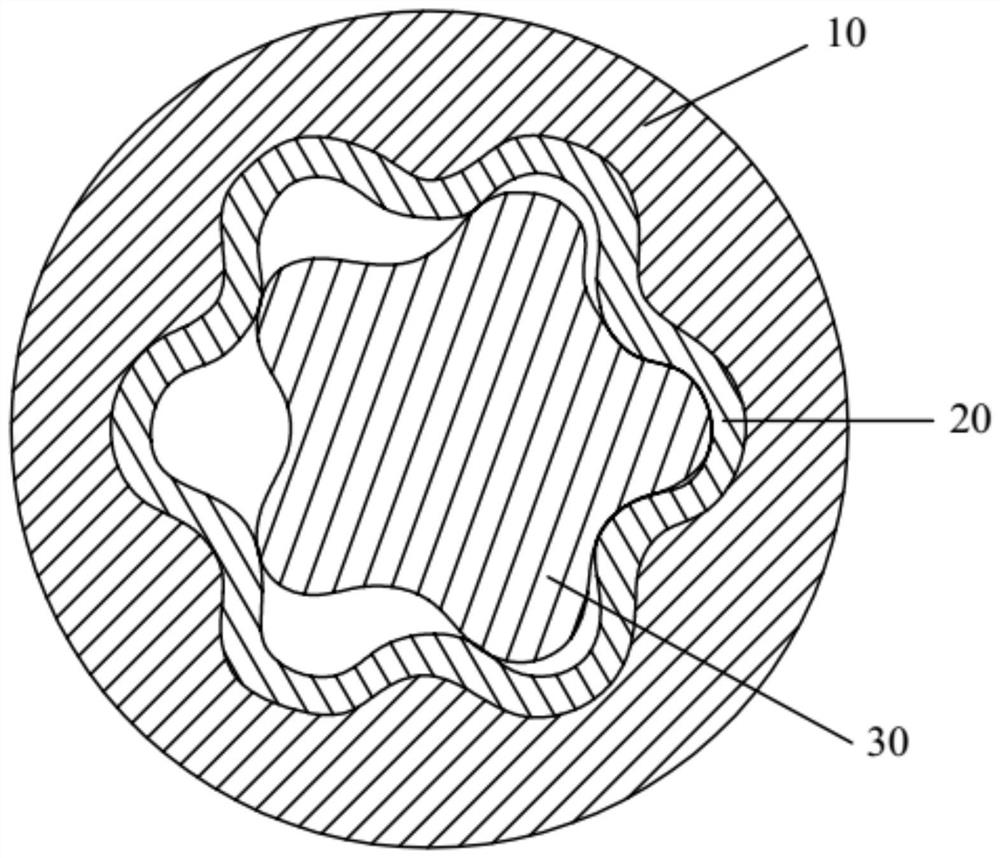

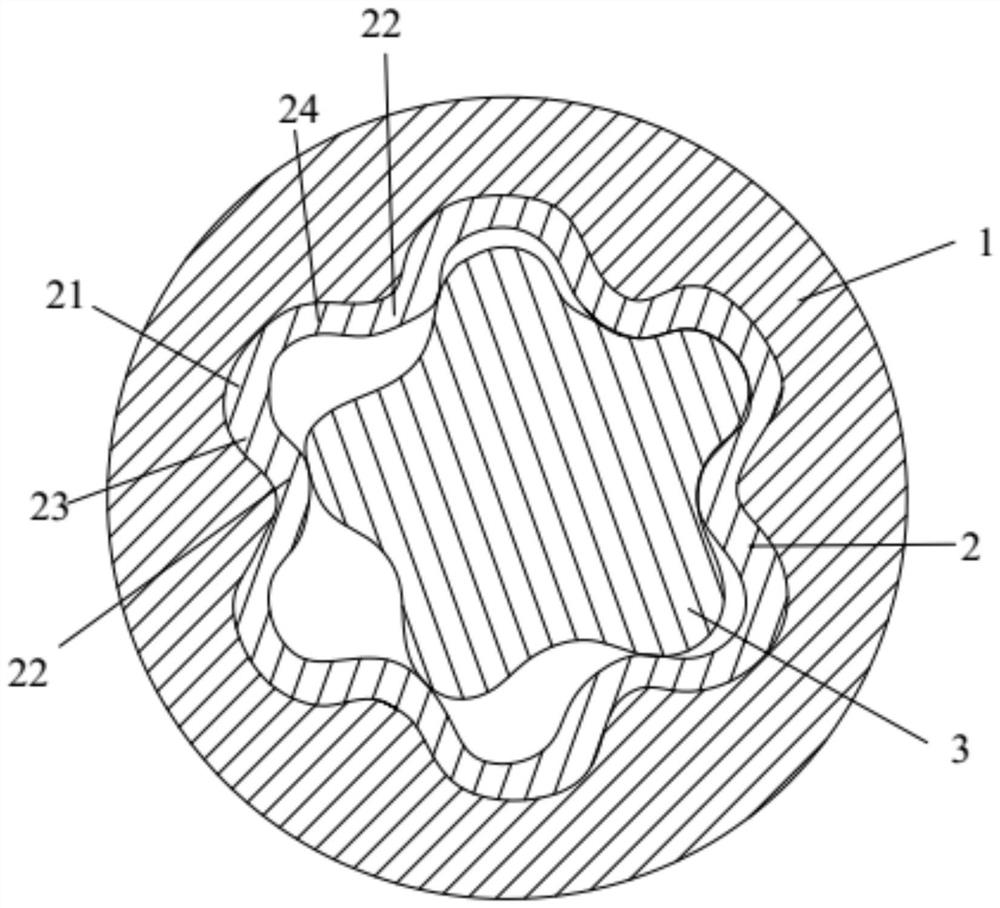

[0028] like image 3 As shown, the present embodiment provides a screw motor, which includes a stator tube 1, a stator bushing 2 and a rotor 3, the stator bushing 2 is penetrated in the stator tube 1 and the outer peripheral surface of the stator bushing 2 and the stator tube are The inner peripheral surfaces of the 1 are fitted together, and the rotor 3 is inserted into the stator bushing 2 . In this embodiment, the stator bushing 2 is an elastic body. When the rotor 3 rotates, the stator bushing 2 is squeezed by the rotor 3, and the stator bushing 2 is in a reciprocating process of compression-rebound-compression.

[0029] In this embodiment, the stator tube 1 is made of steel, its outer peripheral surface is a cylindrical surface, and its inner peripheral surface is annular and corrugated. The outer peripheral surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com