High-elastic non-allergic antibacterial latex used for mattress

A latex and mattress technology, applied in the field of polymer materials, can solve the problems of latex easy oxidation, high cost, slow molding, etc., and achieve the effects of relieving backache, good comfort, and avoiding allergic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

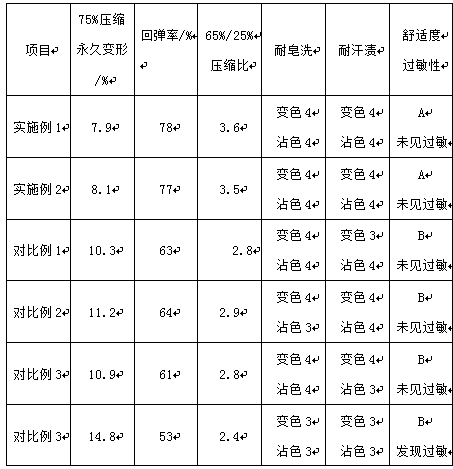

Examples

Embodiment 1

[0022] A high-elastic non-allergic antibacterial latex for mattresses, which is made of the following raw materials in parts by weight: 75 parts of dandelion gum emulsion, 75 parts of guayule emulsion, 15 parts of aloe vera gel, 3 parts of tea residue extract, and Eucommia gum emulsion 25 parts, 8 parts of cassava flour, 1.5 parts of cactus extract, 1 part of terpene resin, 1.5 parts of rosin resin, 1.5 parts of casein, 8 parts of starch.

[0023] A high-elastic non-allergic and antibacterial latex for mattresses, the preparation method of which includes the following steps: (1) Weighing each raw material, mixing dandelion glue emulsion, aloe vera gel, and tea residue extract together and stirring at a high speed at a stirring speed of 200 rpm Minutes, time 15 minutes; (2) Add the mixed solution prepared above, magnesium oxide, and coagulant to the foaming equipment at a weight ratio of 100:2:1 for foaming, and add appropriate amount of air according to the foaming density , t...

Embodiment 2

[0026] A high-elastic non-allergic antibacterial latex for mattresses, which is made of the following raw materials in parts by weight: 75 parts of dandelion gum emulsion, 90 parts of guayule emulsion, 15 parts of aloe vera gel, 3 parts of tea residue extract, and Eucommia gum emulsion 28 parts, 9 parts of tapioca flour, 2 parts of cactus extract, 1 part of terpene resin, 1 part of rosin resin, 1.5 parts of casein, 9 parts of starch.

[0027]A high-elastic non-allergic and antibacterial latex for mattresses, the preparation method of which includes the following steps: (1) Weighing each raw material, mixing dandelion glue emulsion, aloe vera gel, and tea residue extract together and stirring at a high speed at a stirring speed of 200 rpm Minutes, time 15 minutes; (2) Add the mixed solution prepared above, magnesium oxide, and coagulant to the foaming equipment at a weight ratio of 100:2:1 for foaming, and add appropriate amount of air according to the foaming density , to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com