Preparation method of glufosinate intermediate

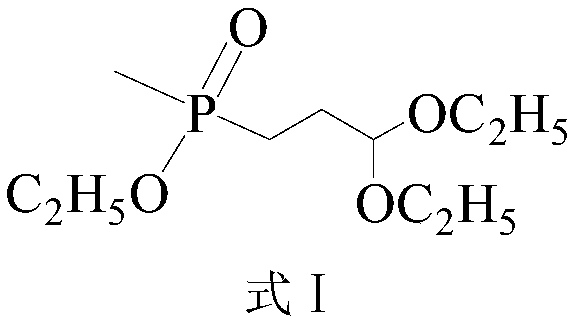

An intermediate, the technology of glufosinate-ammonium, which is applied in the field of preparation of glufosinate-ammonium intermediate 3-phosphonopropyl acetal diethyl alcohol, can solve the problems of low yield and poor atom economy, and achieve high yield and low cost , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 136g diethyl methyl phosphite, 460g dehydrated alcohol and 1.0g heterobimetallic molecular sieve type catalyst CuZr / ZSM-5 (3.5% of the loading capacity of Cu, 2.2% of the loading capacity of Zr) drop into the reaction vessel and mix, cool to 10°C; pass through nitrogen protection, slowly drop 56g of acrolein into the mixed solution, control the dropping temperature at 15-20°C, after the dropwise addition, control the temperature at 25-30°C, react for 4 hours, and depressurize after the reaction Concentrate by distillation and distill off ethanol to obtain 226 g of acetal with a normalized content of 97% and a yield of 92%.

Embodiment 2

[0024] 136g of diethyl methylphosphite, 460g of absolute ethanol and 2.5g of heterobimetallic molecular sieve catalyst CuZr / ZSM-5 (same as Example 1) were put into the reaction vessel and mixed, cooled to 10°C; Slowly add 58g of acrolein dropwise into the mixed solution, the dropping temperature is controlled at 15-20°C, after the dropwise addition is completed, the temperature is controlled at 25-30°C, and the reaction is carried out for 3 hours. The monochemical content is 98%, and the yield is 96%.

Embodiment 3

[0026] 136g diethyl methylphosphite, 460g absolute ethanol and 4.0g heterobimetallic molecular sieve catalyst CuZr / ZSM-5 (same as Example 1) were put into the reaction vessel and mixed, cooled to 10°C; Slowly add 58g of acrolein dropwise into the mixed solution, the dropping temperature is controlled at 15-20°C, after the dropwise addition is completed, the temperature is controlled at 25-30°C, and the reaction is carried out for 1 hour. The monochemical content is 97%, and the yield is 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com