Method for degrading iopromide-containing wastewater

An iopromide and wastewater technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as corrosion of instruments and equipment, and achieve the advantages of reducing degradation cost, good degradation effect and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A method for degrading iopromide wastewater

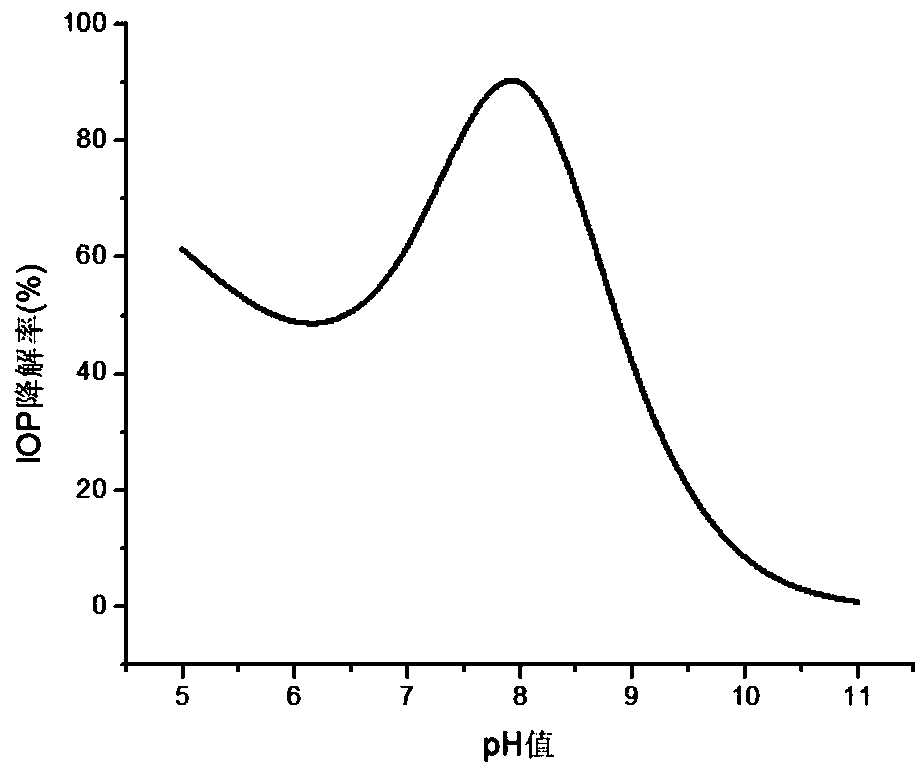

[0025] (1) Effect of pH value on degradation efficiency

[0026] Methods as below:

[0027] 1) Catalyst pretreatment: pass the ferrous sulfide through a 180-200 mesh standard sieve, and take the undersieve to obtain ferrous sulfide powder, which is set aside.

[0028] 2) Take 750 μL of iopromide stock solution with a concentration of 1 mg / mL and 1143 μL of sodium sulfite stock solution with a concentration of 22.05 mg / mL, dilute to volume in a 500 mL volumetric flask, shake and shake well.

[0029] 3) Adjust the circulating water machine to 25°C in advance. After the temperature reaches 25±2°C and stabilizes, pour all the solution in step 2) into the reactor, and adjust it with 0.25M sodium hydroxide or 0.25M sulfuric acid. The pH value of the mixed solution is 5, 7, 8, 9, 11, and then 0.5 g of ferrous sulfide is added. Stir continuously during this period to ensure that the reaction is fully uniform. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com