Garbage can cleaning system with complete functions and using method of system

A technology for cleaning systems and trash cans, applied in garbage cleaning, garbage collection, application, etc., can solve problems such as poor cleaning effect, single cleaning method, and water waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1: (No non-slip protrusion 12, no dust cover 31)

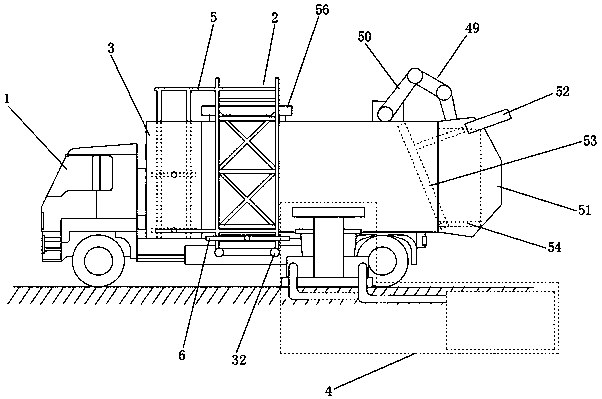

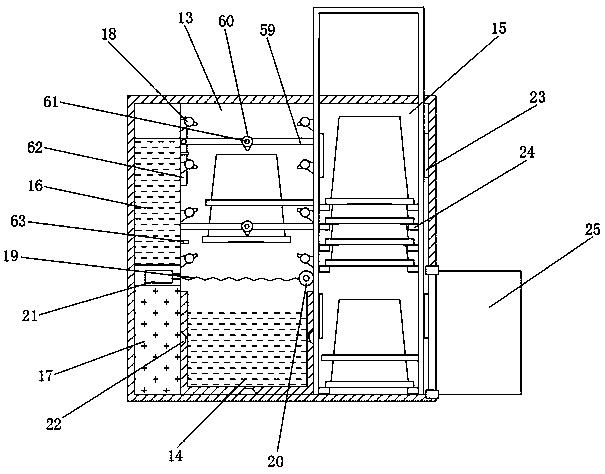

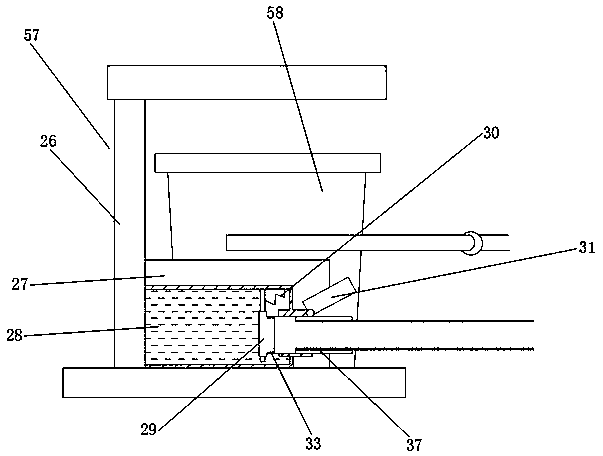

[0044] As shown in the accompanying drawings of the specification, a fully functional garbage can cleaning system includes a car body 1, a bucket clamping device 2, a cleaning system 3, a sewage purification circulation system 4, and a control system; the top of the car body 1 A garbage inlet 56 is provided, and a garbage compression device 49 is provided at the rear; the cleaning system 3 is arranged at the front end of the carriage of the vehicle body 1, close to the garbage inlet 56; the bucket clamping device 2 includes a bucket clamping movable track 5 and Bucket clamp 6; The bucket clamp rail 5 is a double-track circular closed track, initially set on the side of the car body 1, and passes through the cleaning system 3; The bucket clamp 6 has two groups, all of which are placed horizontally The middle of the bucket clamp movable track 5; the cleaning system 3 includes a spray cleaning section 13, an ultrasoni...

Example Embodiment

[0055] Embodiment 2: (with non-slip protrusion 12, without dust cover 31)

[0056] The structure and principle of the second embodiment are basically the same as those of the first embodiment. The difference is that the bucket clamp 6 further includes anti-slip protrusions 12; the anti-slip protrusions 12 are distributed on the inner surface of the grip 11. The anti-slip protrusion 12 plays an anti-slip function when the trash can 58 is clamped.

Example Embodiment

[0057] Example 3: (Without non-slip protrusion 12, with dust cover 31)

[0058] The structure and principle of the third embodiment are basically the same as those of the first embodiment. The difference is that a dust cover 31 is hinged at the foremost ends of the clear water port 28 and the sewage port 38. The dust-proof cover 31 serves as a dustproof function for the clean water port 28 and the sewage port 38.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com