Dust restraining tank of concrete mixing plant

A mixing station and concrete technology, applied in the field of environmental protection equipment, can solve problems such as high maintenance costs, collapse of dust-proof nets, and considerable environmental pollution, and achieve the effects of alleviating internal air pressure, reducing emission pollution, and improving filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

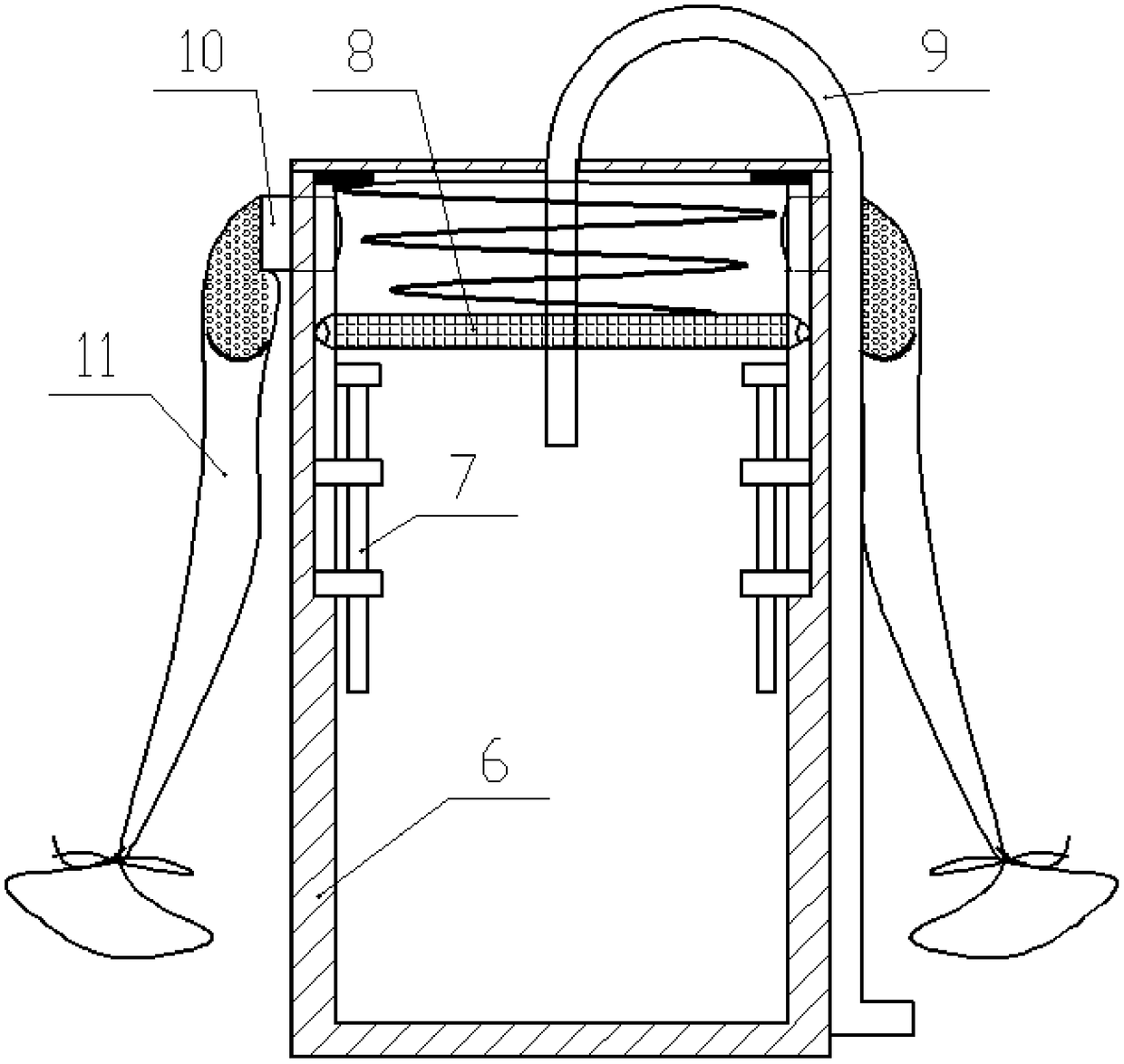

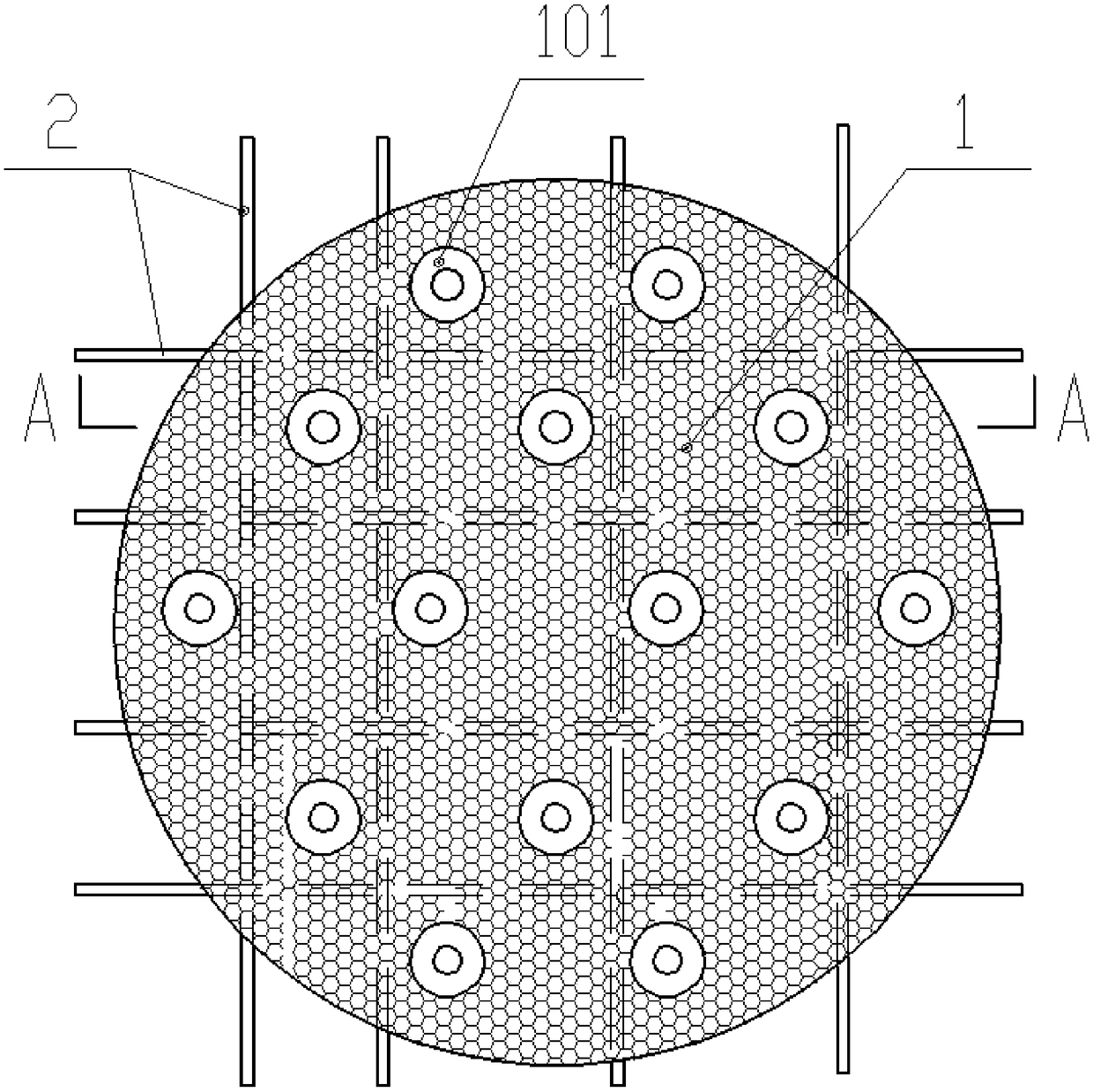

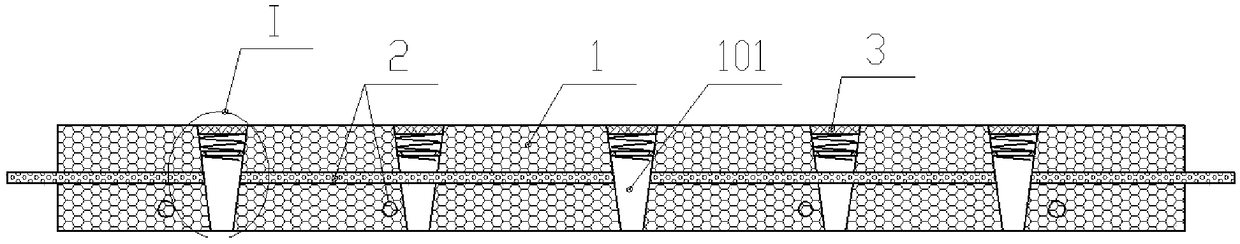

[0027] like figure 1 As shown, a concrete mixing plant dust suppression powder tank includes a cylindrical tank body 6, a feeding pipe 9 is provided on the outside of the tank body 6, the top of the feeding pipe 9 is n-shaped and the outlet end extends into the tank body 6, The top of the tank body 6 is closed, and the outlet end of the feed pipe 9 extends downward into the top of the tank body 6 and passes through the filter plate assembly 8 horizontally arranged in the tank body 6. The filter plate assembly 8 is disc-shaped and has a circumference of A number of balls are arranged on the edge, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com