Movable prefabricated member sunlight temperature-rise maintenance system and method

A technology for prefabricated components and maintenance systems, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to achieve ventilation in residential areas, pollution of curing kilns, etc. The effect of total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

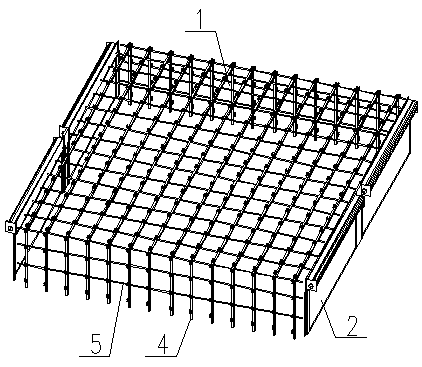

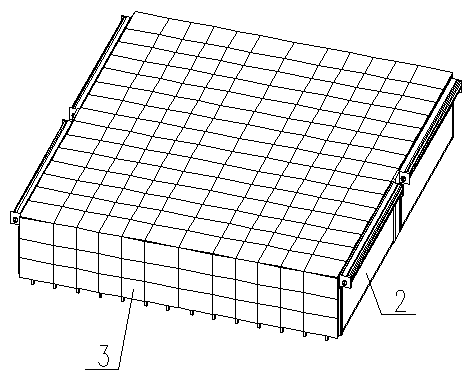

[0038] A solar heating maintenance system for movable prefabricated components, which comprises: a maintenance shed, the maintenance shed is composed of a structural frame body 1, an open type shed door 2 and a heat-absorbing and heat-preservation panel 3, on the structure frame body Install the heat-absorbing and heat-preserving panel, the heat-preserving panel increases the temperature in the curing shed by absorbing sunlight, the structure frame is a structure formed by connecting the main keel 4 and the secondary keel 5, the described The curing shed is equipped with an auxiliary heating device, which provides heat by burning coal, gas, diesel engine, etc., and performs maintenance work on the prefabricated components by adjusting the humidity. The open shed door is set at the entry and exit position of the prefabricated components. A mobile production line is set outside the above-mentioned curing shed.

Embodiment 2

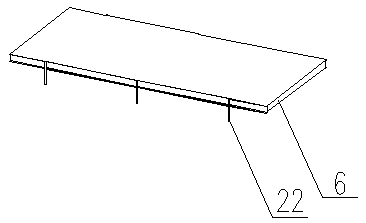

[0040] According to the movable prefabricated component sunlight heating maintenance system described in embodiment 1, a mold table moving line is set on the mobile production line, and a walking mold table 6 is set on the mold table moving line, and the mold table moves The line is composed of two rows of linearly arranged ground wheels 7 and a drive motor 8. The ground wheels are used to support the mold table made of prefabricated components, and the distance between the ground wheels ensures that the mold table of prefabricated components moves forward and provides continuous support. , the ground wheels are installed on the support frame 9, the top of the support frame is provided with wheels 10, the wheels rotate 360 degrees along their own central axis, the driving motor is arranged between the ground wheels, and two rows of ground wheels are arranged alternately, The mold table is in continuous contact with the drive motor during the forward process, and the drive mot...

Embodiment 3

[0042]According to the movable prefabricated component sunlight heating maintenance system described in embodiment 1 or 2, the shuttle car track 12 is arranged in the vertical direction of the moving line of the mold table, and the shuttle car 13 is arranged on the shuttle car track, and the ferry car There is a ferry frame body 14 on the car, the bottom of the frame body is provided with traveling wheels 15, the travel wheels are provided with a driving device, and the top of the frame body is provided with a jacking device 16, and the jacking device can lift and falling, the mold table is lifted by the ferry car and walks on the track to realize the circulation of the mold table on different mold table moving lines. The mobile production line provides cleaning stations, scribing stations, formwork support stations, release agent painting stations, tendon binding stations, pre-embedded parts pre-embedded stations, and cloth stations for the production of prefabricated componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com