Punching mold for permanent magnet motor rotor

A technology of rotor punching and permanent magnet motors, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of long manufacturing cycle and cost at least hundreds of thousands of yuan, and achieve positioning High precision, improve product processing efficiency, and ensure the effect of punching product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings. This set of molds is processed in strict accordance with the requirements of the drawings, and according to the stamping process when stamping. The stamped pieces achieve the expected effect.

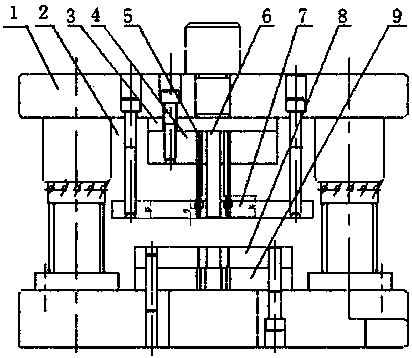

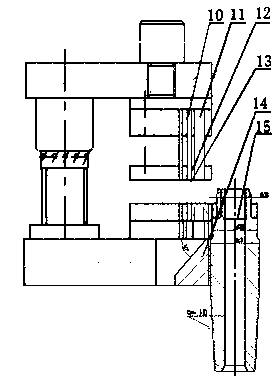

[0030] like Figure 1-3 As shown, the permanent magnet motor rotor punching single punching die includes a mold base 1, an upper die backing plate 3, a punch fixing plate 4, a flux leakage hole punch 5, a small magnetic steel groove punch 6, a lower die 8, a lower die Die base 16, lower die backing plate 9, large magnetic steel groove punch 10, weight reduction hole punch 11, small flux leakage hole punch 12, large flux leakage hole punch 13, center positioning shaft 14; Two gap-free rolling guide columns are connected to the upper and lower mold bases, the center of the lower end surface of the mold base 1 is provided with an upper mold backing plate 3, the lower end of the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com