A composition for carbon catalytic hydrogenation to methane

A technology of catalytic hydrogenation and composition, applied in catalyst activation/preparation, chemical/physical process, physical/chemical process catalyst, etc., to achieve the effect of reducing cost and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

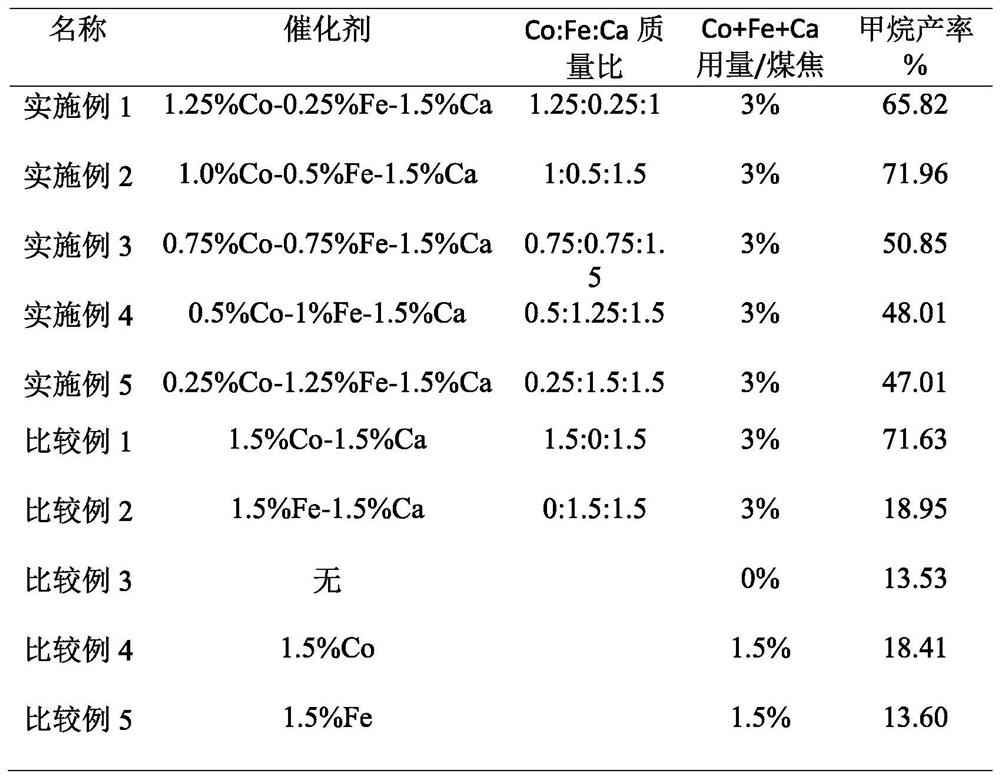

Examples

Embodiment 1

[0027] Weigh 0.0617g of Co(NO 3 ) 2 ·6H 2 0.0.0181g of Fe(NO 3 ) 3 9H 2 O, 0.0884g of Ca(NO 3 ) 2 4H 2 O is evenly mixed and placed in a small beaker, and 0.7ml of deionized water is added to ultrasonically uniformly prepare a mixed solution. Add 1 g of coal char (20-60 mesh) to the above mixed solution, ultrasonically impregnate it for 2 hours, put it in a blast drying oven at 105°C for 24 hours, and put it in a desiccator for storage after cooling to room temperature.

[0028] Put the above-treated coal char into a fixed-bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, and hydrogen flow rate 50ml / min to obtain product methane.

Embodiment 2

[0030] Weigh 0.0496g of Co(NO 3 ) 2 ·6H 2 O, 0.0362g of Fe(NO 3 ) 3 9H 2 O, 0.0884g of Ca(NO 3 ) 2 4H 2 O mixed and placed in a small beaker, adding 0.7ml of deionized water and ultrasonically uniformly prepared a mixed solution. Add 1 g of coal char (20-60 mesh) to the above mixed solution, ultrasonically impregnate it for 2 hours, put it in a blast drying oven at 105°C for 24 hours, and put it in a desiccator for storage after cooling to room temperature.

[0031] Put the above-treated coal char into a fixed-bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, and hydrogen flow rate 50ml / min to obtain product methane.

Embodiment 3

[0033] Weigh 0.0372g of Co(NO 3 ) 2 ·6H 2 O, 0.0543g of Fe(NO 3 ) 3 9H 2 O, 0.0884 Ca(NO 3 ) 2 4H 2 O mixed and placed in a small beaker, adding 0.7ml of deionized water and ultrasonically uniformly prepared a mixed solution. Add 1 g of coal char (20-60 mesh) to the above mixed solution, ultrasonically impregnate it for 2 hours, put it in a blast drying oven at 105°C for 24 hours, and put it in a desiccator for storage after cooling to room temperature.

[0034] Put the above-treated coal char into a fixed-bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, and hydrogen flow rate 50ml / min to obtain product methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com