A method for preparing noble metal aerogels based on ligand self-assembly

A noble metal and aerogel technology, applied in aerosol preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low mass transfer speed of low-dimensional noble metal nanomaterials and the utilization of noble metal atoms Low efficiency and other problems, to achieve the effect of electrocatalytic hydrogen evolution with high catalytic activity, wide application range and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

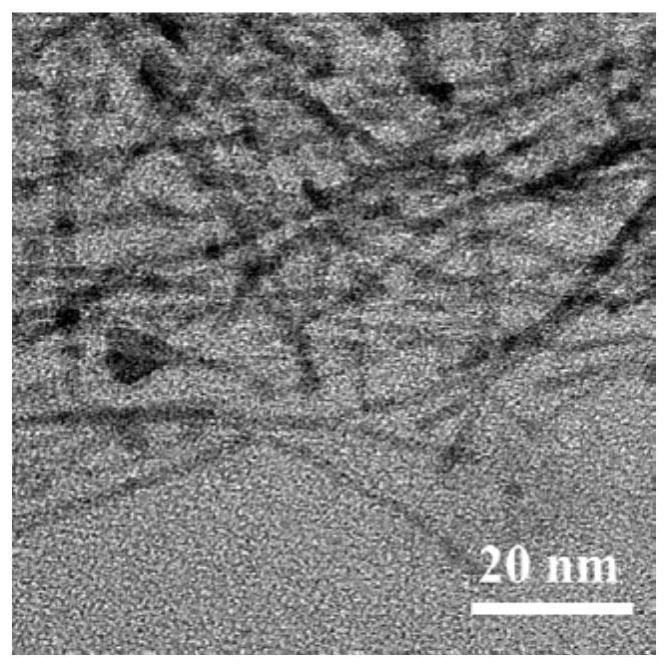

[0036] 1. (a) Dissolve 50 mg (0.07 mmol) of glutamic acid derivative 1 in 15 mL of tetrahydrofuran, and add 500 μL of platinum nanowire ethanol solution under stirring at room temperature (according to the document J.Am.Chem.Soc.2013, 135 , prepared by the method disclosed in 9480-9485, wherein the Pt nanowire is composed of a nanobeam formed by a single nanowire with a diameter of 1-3 nm and a length of 3-5 μm), and then placed in a light-proof condition at 30-40 ° C After stirring for 12 hours, the obtained black product was repeatedly centrifuged and washed 3 to 5 times with tetrahydrofuran.

[0037] (b) Dissolve 50mg (0.07mmol) of glutamic acid derivative 1 in 15mL of tetrahydrofuran, add the black product after centrifugation and washing in step (a) under the condition of stirring at room temperature, and then stir at 30-40°C under the condition of avoiding light After 12 hours, the black product obtained was repeatedly centrifuged and washed 3 to 5 times with tetrahydrof...

Embodiment 2

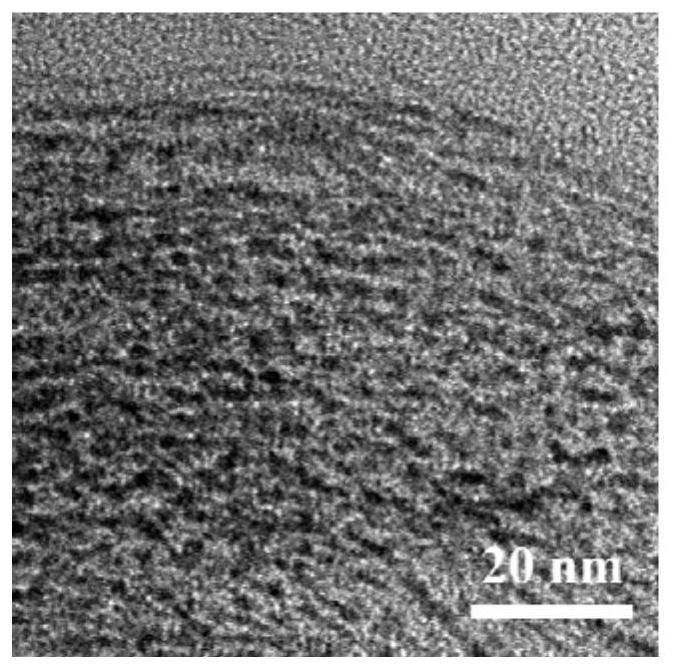

[0043] The functionalized Pt-L1 nanomaterial was prepared according to the method of Example 1. 25 mg of functionalized Pt-L1 nanomaterials were ultrasonically dispersed in 0.3 mL of toluene, heated at 50 °C for 5 min, and then naturally cooled to room temperature to form a stable gel, which was passed through supercritical CO 2 After drying, Pt airgel was obtained.

Embodiment 3

[0045] 1. (a) Dissolve 60 mg (0.07 mmol) of glutamic acid derivative 2 in 15 mL of tetrahydrofuran, and add 500 μL of platinum nanowire ethanol solution under stirring at room temperature (according to the document J.Am.Chem.Soc.2013, 135 , prepared by the method disclosed in 9480-9485, wherein the Pt nanowire is composed of a nano-beam formed by a single nanowire with a diameter of 1-3 nm and a length of 3-5 μm), and then in the dark Stirring at 30-40°C for 12 hours under the condition, the obtained black product was repeatedly centrifuged and washed 3-5 times with tetrahydrofuran.

[0046](b) Dissolve 60mg (0.07mmol) of glutamic acid derivative 2 in 15mL of tetrahydrofuran, add the black product after centrifugation and washing in step (a) under the condition of stirring at room temperature, and then stir at 30-40°C under the condition of avoiding light After 12 hours, the black product obtained was repeatedly centrifuged and washed 3 to 5 times with tetrahydrofuran.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com