Liquid storage method and storage device

A storage method and liquid storage technology, which is applied in the field of devices for storing atomizable liquids, can solve the problems of inconvenient injection of e-liquid, limited storage time, long production cycle, etc., and achieve short delivery cycle, diverse shapes, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

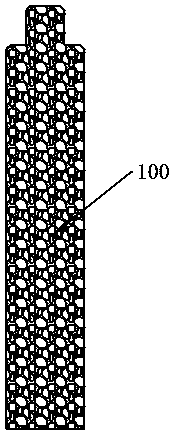

[0017] Embodiment 1, this embodiment is a liquid storage device used to store e-liquid in electronic cigarettes, such as figure 1 As shown, in this embodiment, the liquid storage device 100 is in the shape of a cylinder as a whole, and it is formed of a porous material. The porous material can be ceramic materials such as silicon carbide and alumina, and porous metal materials such as stainless steel, copper, and nickel. The pore size of the porous material is 5-100µm. The pores of the porous material are used to store the e-liquid, and the e-liquid enters the pores of the porous material through the principle of capillary and siphon. In practice, the porosity of the porous material can be adjusted to adjust the liquid storage capacity by adjusting the porosity. The general porosity can be 40%, and the appropriate porosity can be selected between 20% and 70% according to the needs.

[0018] The storage of the liquid storage device used for storing e-liquid in this embodiment ...

Embodiment 2

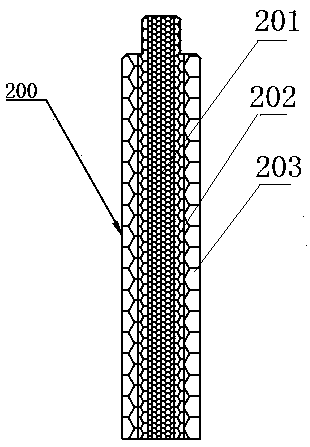

[0021] Embodiment 2, this embodiment is a storage device that simultaneously stores different liquids, such as figure 2 As shown, in this embodiment, the liquid storage device 200 is divided into three layers according to needs, and different layers may have different porosity, and the pore sizes of layers are arranged in an increasing or decreasing trend, and can be used to store different liquids, Such as figure 2 As shown, in this embodiment, it is divided into three layers: respectively, the inner layer liquid storage core 201 with a pore size of 5-50 μm in the middle, which is used to store liquid with relatively small molecular group particles, and the outer pore diameter of the liquid storage core is 30 μm. The intermediate storage layer 202 of -70 μm is used to store liquids with smaller molecular clusters, and the outer storage layer 203 of 50-100 μm is used to store liquids with larger molecular clusters. We all know that different liquids have different molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com