Silage method for forage grass

A green storage and cellar technology, applied in the field of breeding, can solve problems such as uncontrollable conditions, single raw materials, and uncertain quality of green storage, and achieve the effects of avoiding resource waste, increasing storage time, and reducing possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

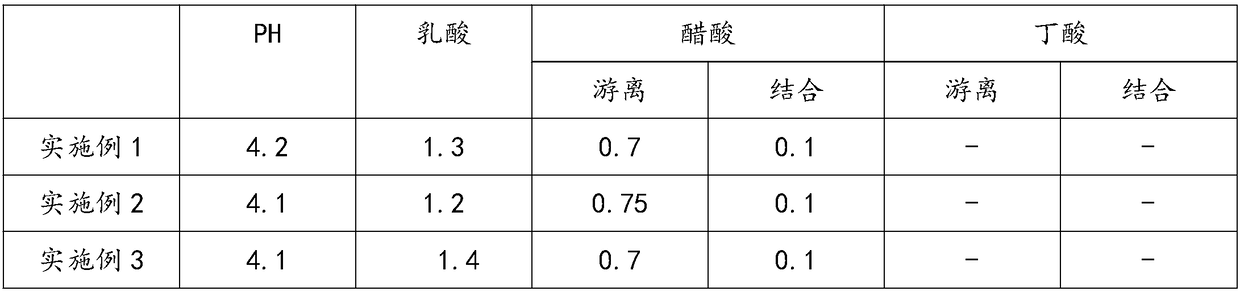

Embodiment 1

[0030] A method for forage green storage is characterized in that it comprises the following steps:

[0031] (1) Preparation of silage equipment: choose a location with high terrain, dry, hard soil and good drainage close to the livestock house to dig a cellar. The shape of the cellar excavation is a rectangular roof type, and the surrounding feet are arc-shaped. Each cubic meter can be filled with 325kg of filler. , Before installing the cellar, lay 15cm thick straw on the bottom of the cellar, spread polyethylene plastic film around the cellar, so that the polyethylene plastic film is completely wrapped around the cellar, and dig 4 drainage ditches around the cellar.

[0032] (2) Raw material processing: cut the harvested fresh raw material forage grass into a length of 2cm, adjust the water content of the fresh raw material after cutting, so that the water content of the cut raw material is 60%, and when the water content is higher than 60%, the raw material is processed Ai...

Embodiment 2

[0037] A method for forage green storage is characterized in that it comprises the following steps:

[0038](1) Preparation of silage equipment: choose a location with high terrain, dry, hard soil and good drainage close to the livestock house to dig a cellar. Filling can be 325kg per cubic meter. Before installing the cellar, lay 12cm thick straw on the bottom of the cellar and surround the cellar. Lay plastic polyethylene film so that the polyethylene plastic film is completely wrapped around. Dig 4 drainage ditches around the cellar. During the storage process, the cellar must not leak, so regular inspections are required to check for water leakage.

[0039] (2) Raw material processing: cutting the harvested fresh raw material forage grass and sweet potato into a length of 3 cm, and regulating the moisture content of the fresh raw material after cutting, so that the moisture content of the raw material after cutting is 65%, and when the moisture content is higher than 65%, t...

Embodiment 3

[0044] A method for forage green storage is characterized in that it comprises the following steps:

[0045] (1) Preparation of silage equipment: choose a location with high terrain, dry, hard soil and good drainage close to the livestock house to dig a cellar. Filling can be 325kg per cubic meter. Before installing the cellar, lay 15cm thick straw on the bottom of the cellar and surround the cellar. Spread polyethylene plastic film so that the polyethylene plastic film is completely wrapped around the cellar. Dig 4 drainage ditches around the cellar. During storage, the cellar must not leak, so regular inspections are required to see if there is any water leakage.

[0046] (2) Raw material processing: cutting the twigs of the harvested fresh raw materials pasture grass, sweet potato, sugar beet, leaves and small shrubs into lengths of 5 cm, and regulating the moisture content of the fresh raw materials after cutting, so that the moisture content of the raw materials after cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com