Efficient silage preparation method

A silage and silage technology, which is applied in the field of high-efficiency silage preparation, can solve problems such as limitations and production obstacles, and achieve the effects of improving feed utilization, easy storage, and increasing feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

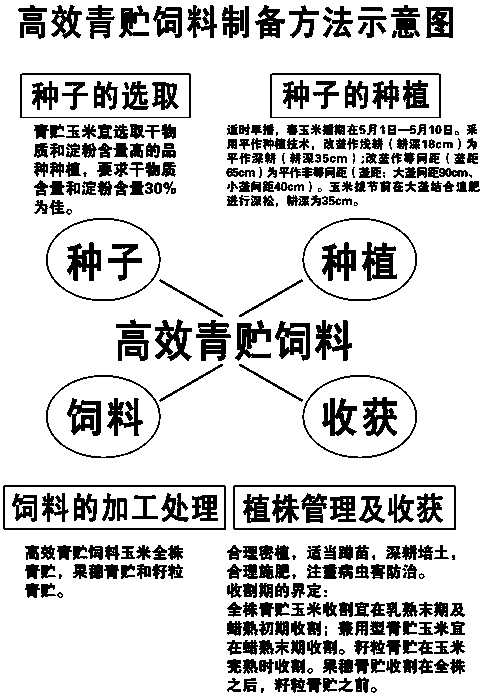

[0014] Specific implementation mode one: as figure 1 and figure 2 As shown, what is recorded in this embodiment is a method for preparing high-efficiency silage. The method is completed in four steps: raw material seed selection, raw material seed planting, raw material plant management and harvesting, and feed processing; each step is specifically as follows: :

[0015] Step 1: Selection of raw material seeds: select corn varieties for both grain and feed, including: Jinling silage 37, Jinling silage 418, Jinling silage 10, Jinling silage 27, and Jinling silage 367 varieties; Type corn variety Jinling silage 418 dry matter 32.4, Jinling silage 37 starch content 30.33;

[0016] Step 2: Raw material seed planting: timely sowing, spring corn is sown when the soil temperature is stable at 10°C in the 5-10cm soil layer, and the sowing date is from May 1st to May 10th. The planting method adopts the flat planting planting technique , changing the conventional tillage method fro...

specific Embodiment approach 2

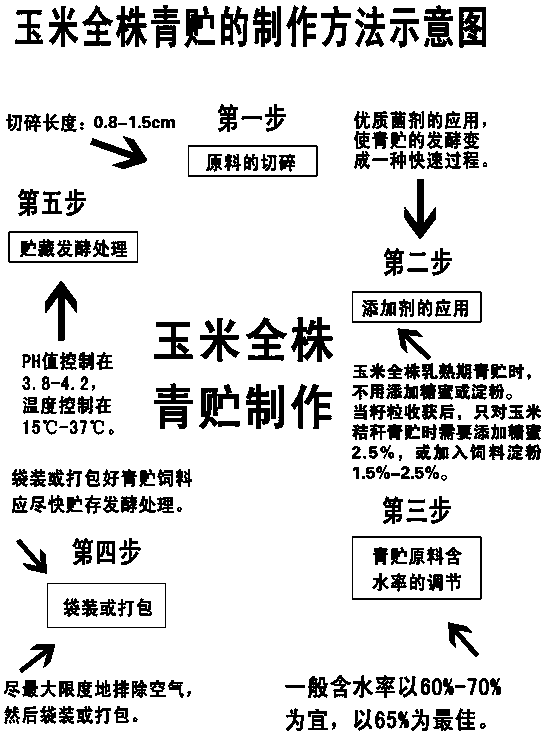

[0019] Specific embodiment two: the preparation method of a kind of high-efficiency silage described in specific embodiment one, in step four, the application of silage additive, add soluble sugar or starch and microbial bacterial agent to corn stalk after cutting; Soluble sugar ( Such as molasses) addition amount: add 2.5% to corn stalk silage; or add starch, its addition amount: add 1.5%~2.5% feed starch to corn stalk silage; add microbial agents, there are special microbial agents for silage on the market for selection , the amount added is subject to the instructions on the packaging bag, which can speed up the fermentation process.

specific Embodiment approach 3

[0020] Embodiment 3: In the method for preparing high-efficiency silage described in Embodiment 1, in step 4, the moisture content of the silage raw material is controlled between 60% and 70%, subject to 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com