A fully-displacement amplified piezoelectric inchworm straight-line platform

A displacement amplification, electric inchworm technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. It can reduce the problems such as reducing the horizontal swing error and vertical pitch error, reduce the requirements of processing and assembly accuracy, and increase the single-step displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

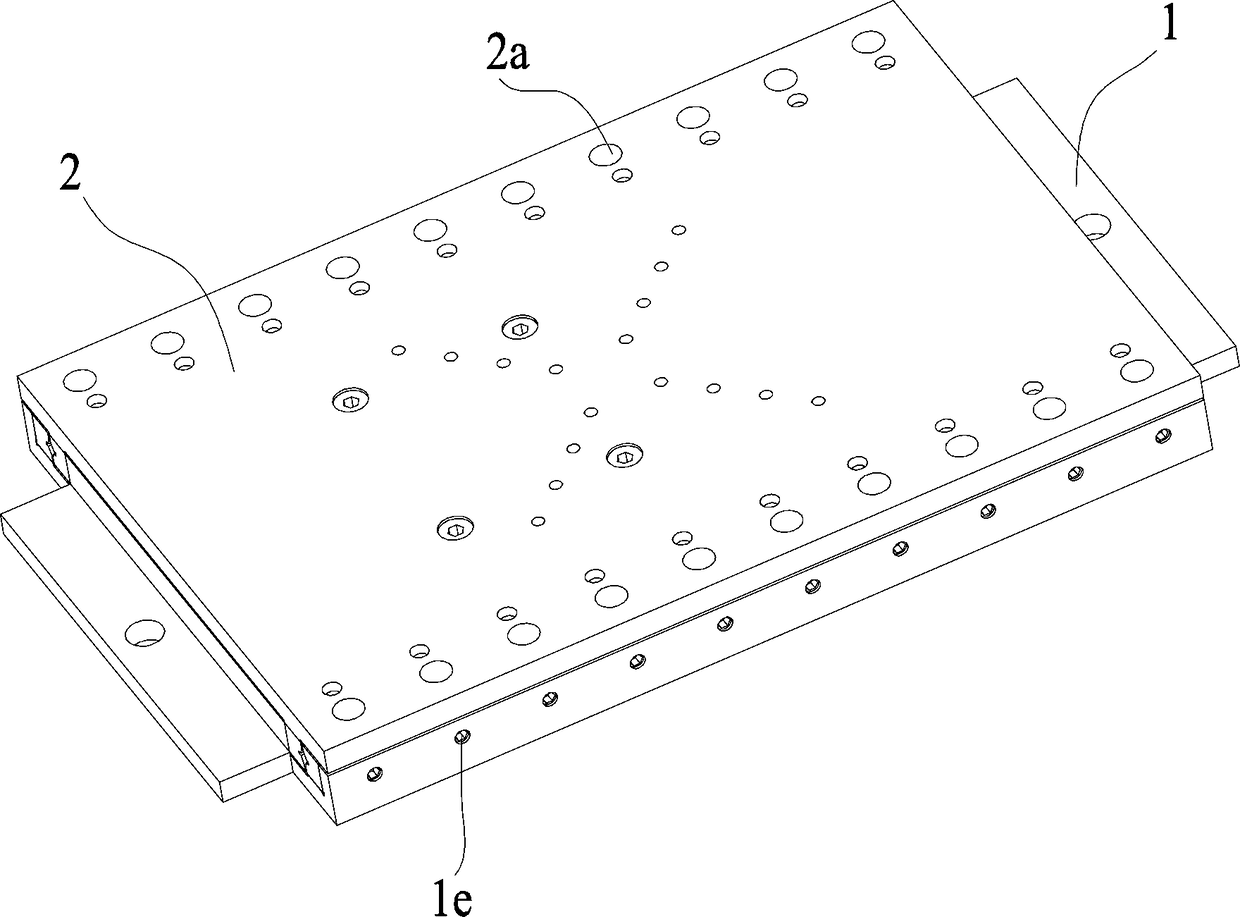

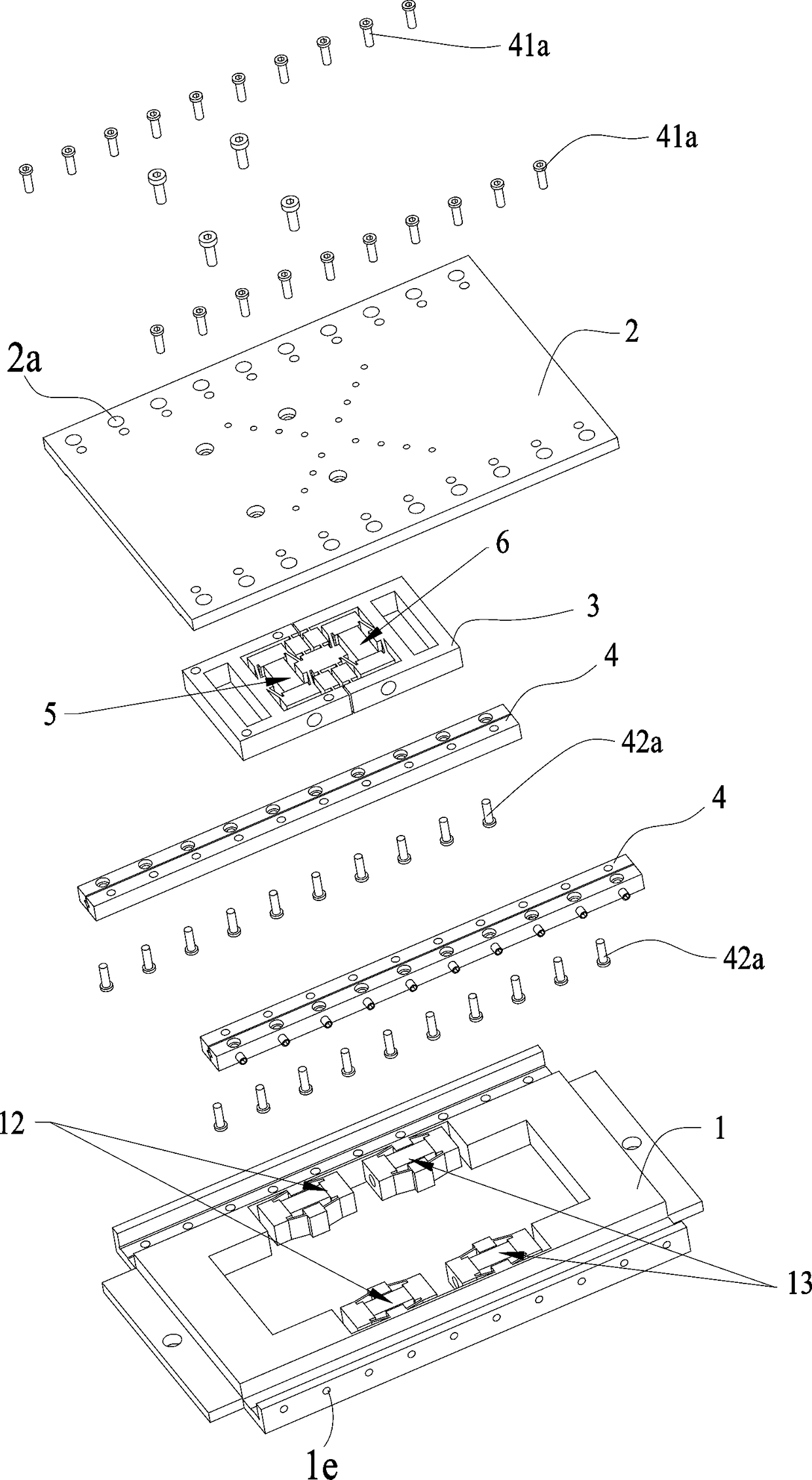

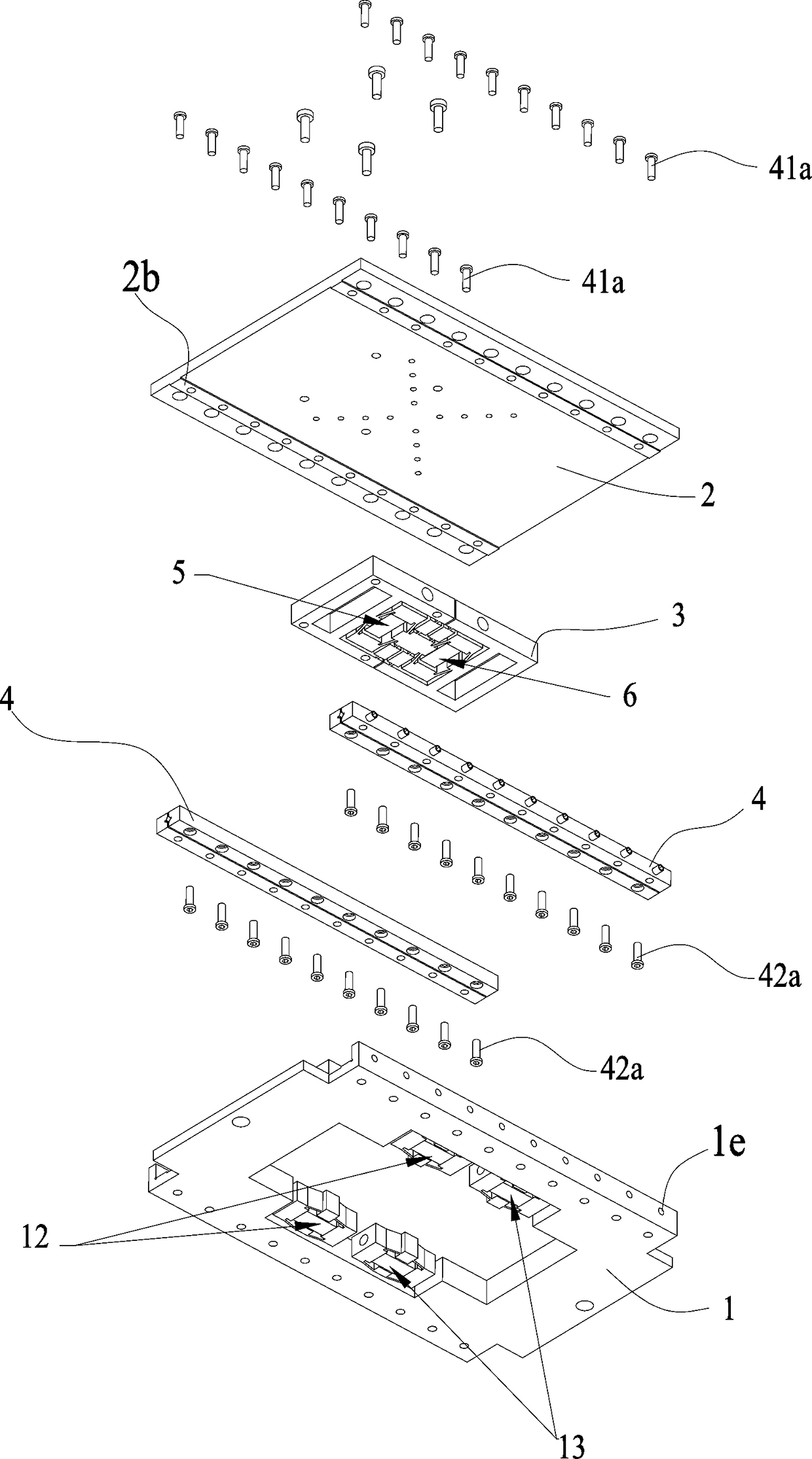

[0040] Figure 1 to Figure 10 It is a structural schematic diagram of the present invention, as shown in the figure, a full-displacement amplified piezoelectric inchworm linear platform of the present invention includes a fixed platform 1 and a moving table 2 slidingly connected by cross roller guide rails 4, and the fixed platform 1 is provided with The slideway 1a is provided with a mover 3 inside the slideway 1a. The mover 3 includes a first frame body 31 and a second frame body 32 arranged along the length direction of the slideway 1a. Between the first frame body 31 and the second frame body 32 There is a movable gap 3a between them, the first frame body 31 is fixed on the moving platform 2, and the first frame body 31 and the second frame body 32 are respectively connected with the first drive unit 5 and the second drive unit 5 which expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com