Pressurized water nuclear reactor sleeve type standby shutdown system and method

A technology for nuclear reactors and shutdown systems, which is applied in the fields of reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of mixing liquid neutron absorbers with primary circuit coolants, shorten the restart interval, save system layout space, and save The effect of cleaning workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

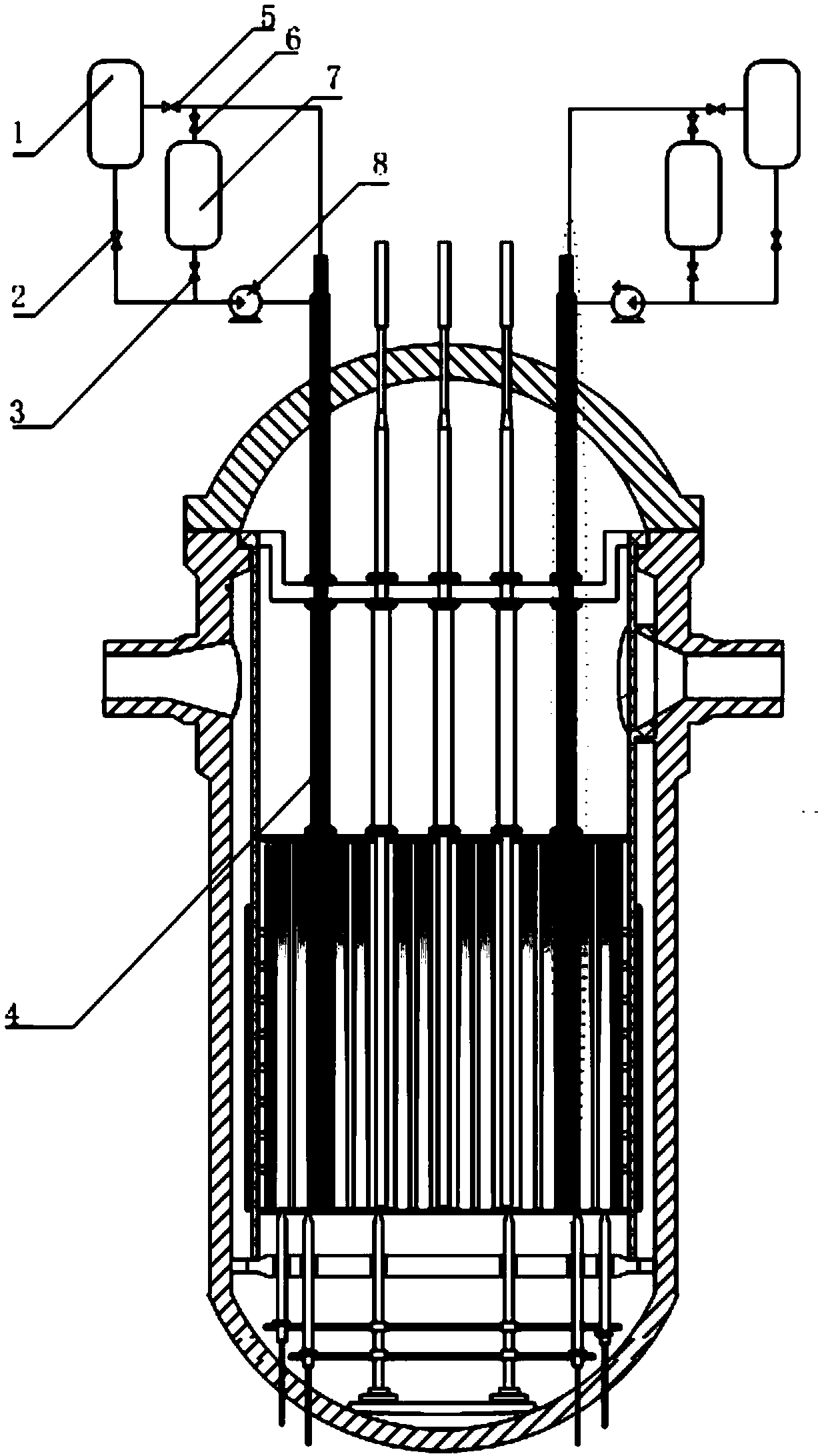

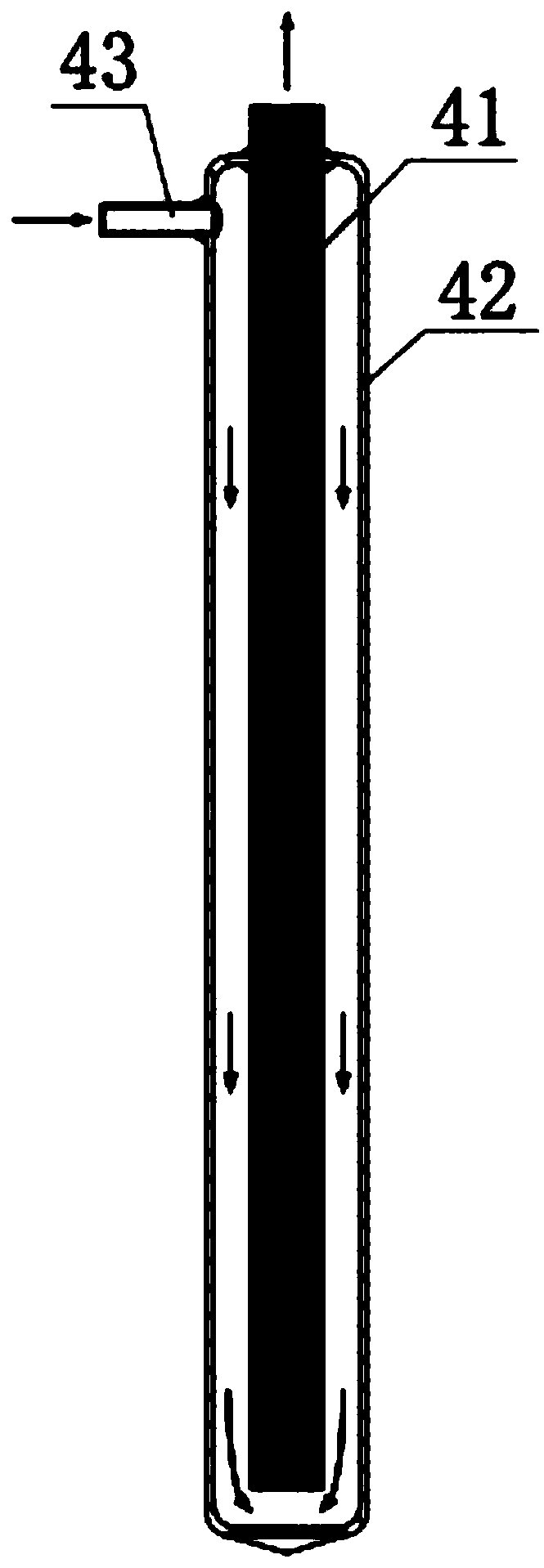

[0045] Such as figure 1 , figure 2 As shown, the casing-type backup shutdown system of a pressurized water nuclear reactor includes a casing-type injection unit 4 arranged in the pressure vessel and a shutdown fluid circulation system arranged outside the pressure vessel, and the casing-type injection unit 4 is inserted into the reactor In the core, the sleeve type injection unit 4 includes an inner sleeve 41 and an outer sleeve 42 arranged outside the inner sleeve 41, the lower end of the inner sleeve 41 is an open structure, and the outer sleeve 42 is a closed structure , There is a certain gap between the lower end of the inner sleeve 41 and the bottom of the outer sleeve 42, specifically, the gap between the lower end of the inner sleeve 41 and the bottom of the outer sleeve 42 is greater than or equal to the inner diameter of the inner sleeve 41 , the upper end of the inner casing 41 protrudes from the top of the outer casing 42, the side wall of the outer casing 42 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com