A test tool for a shift fork system

A tooling and mounting frame technology, applied in the field of fork system test tooling, can solve the problems of time-consuming, cumbersome test work, low efficiency, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

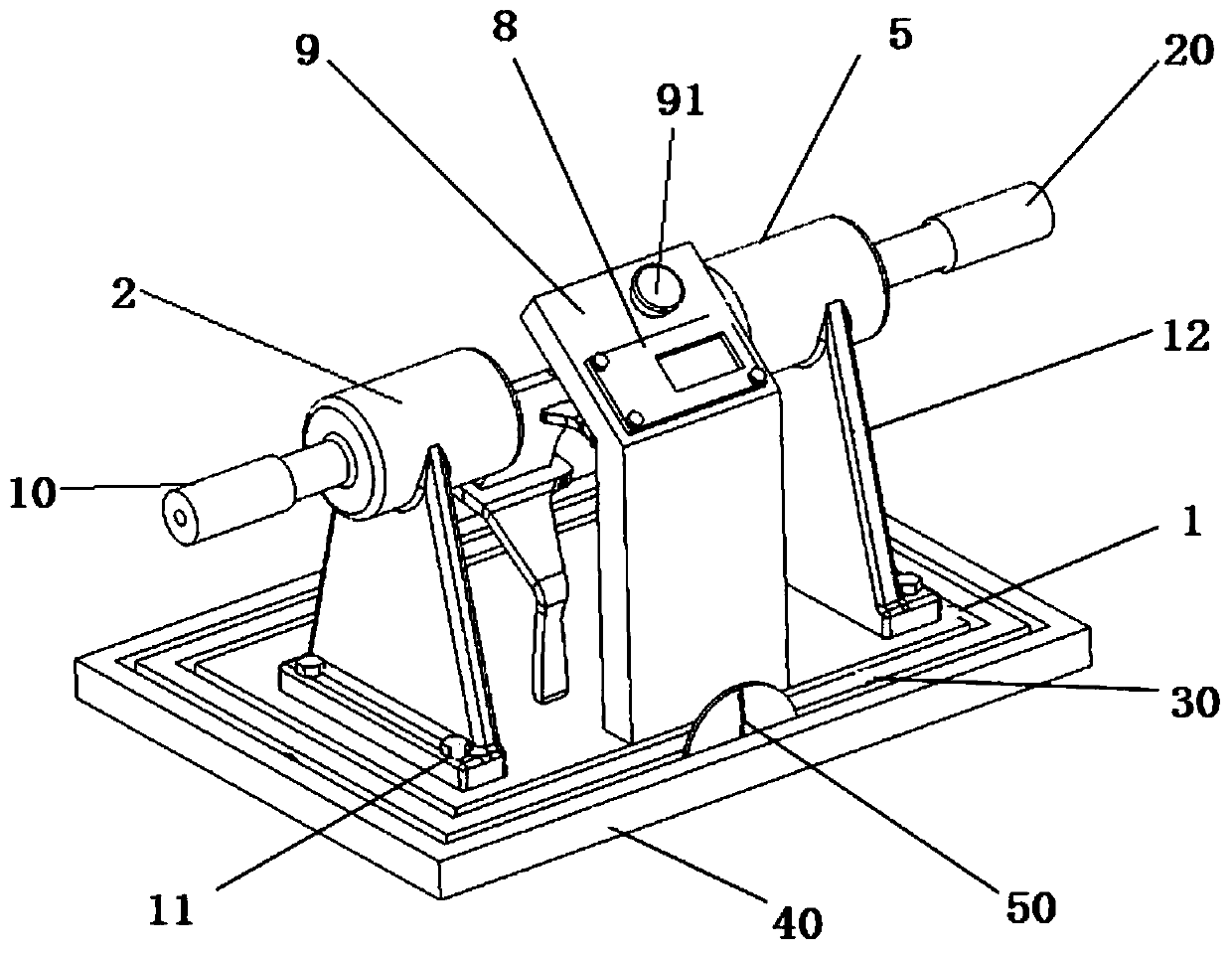

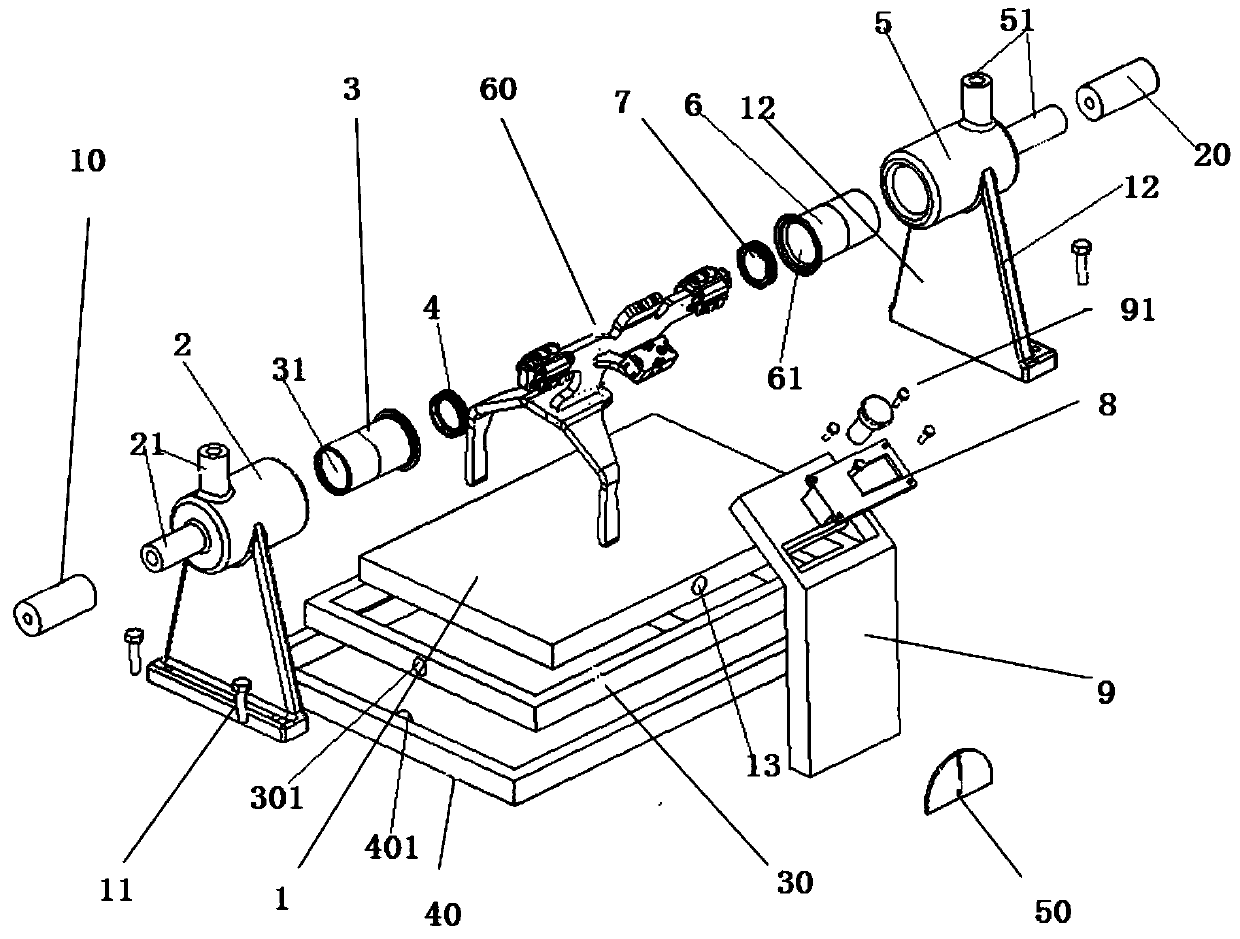

[0027] Embodiments of the present invention: as figure 1 with figure 2 As shown, a test tool for a shift fork system is disclosed, including a base 1, a first cylinder liner fixing tube 2, a first cylinder liner 3, a first piston 4, a second cylinder liner fixing tube 5, a second cylinder liner 6, Second piston 7 and displacement sensor 8;

[0028] The base 1 is provided with a first bracket 11 and a second bracket 12 at intervals; the bottom end of the first bracket 11 is fixed on the base 1 by bolts, and the first bracket 11 is used to fix the first cylinder liner fixing pipe 2. The bottom end of the second bracket 12 is fixed on the base 1 by bolts, and the second bracket 12 is used for fixing the second cylinder liner fixing pipe 2 .

[0029] The first cylinder liner fixing pipe 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com