Design method for multi-functional measuring area of large-sized underwater acoustic measurement test vessel

A technology of underwater acoustic measurement and measurement area, which is applied in the field of ships, can solve the problems of insufficient capacity and capacity of the test site, few measurement areas, and unsatisfactory problems, so as to improve production and scientific research capabilities, improve overall performance, and achieve huge military benefits and social benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

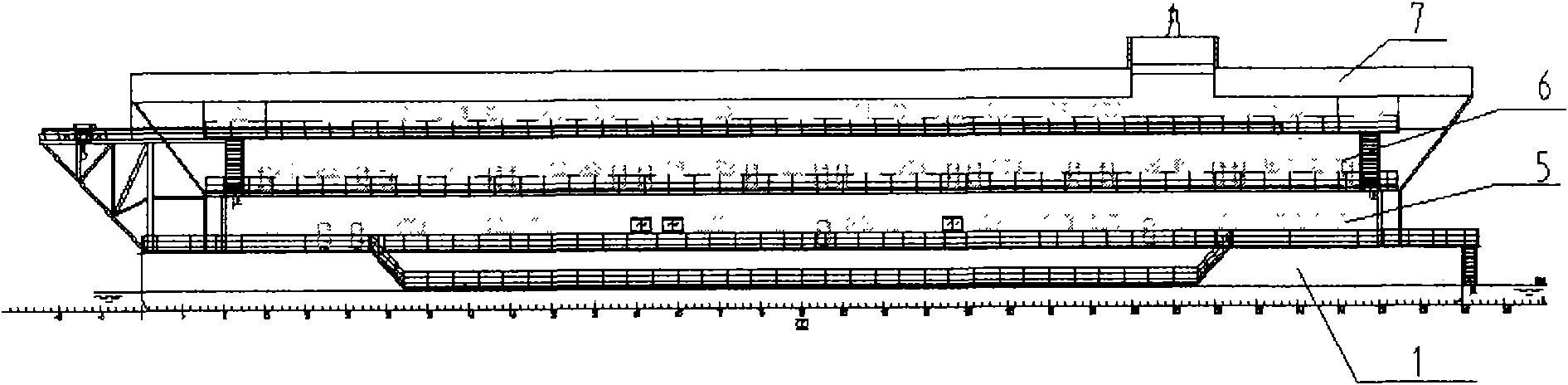

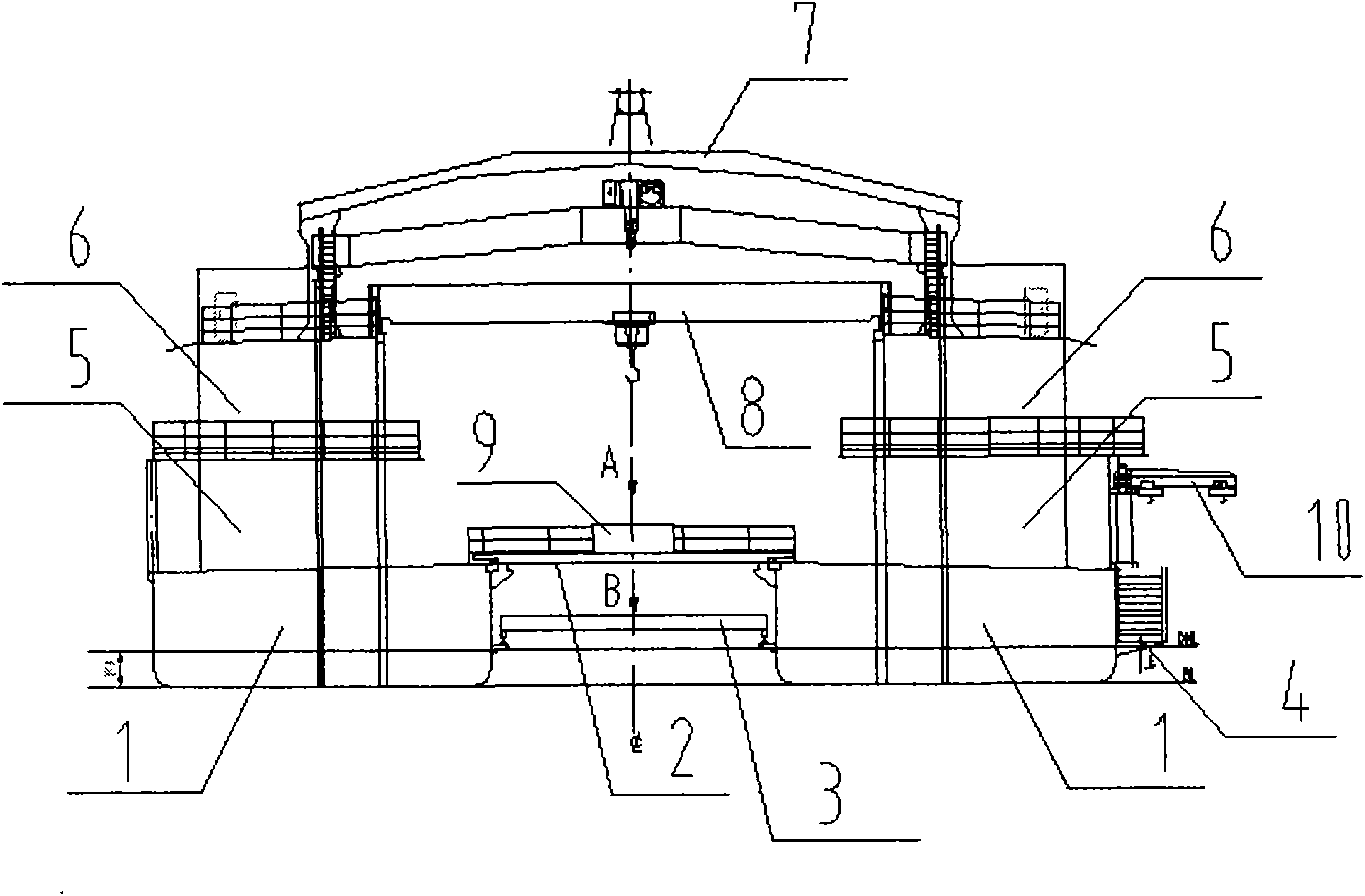

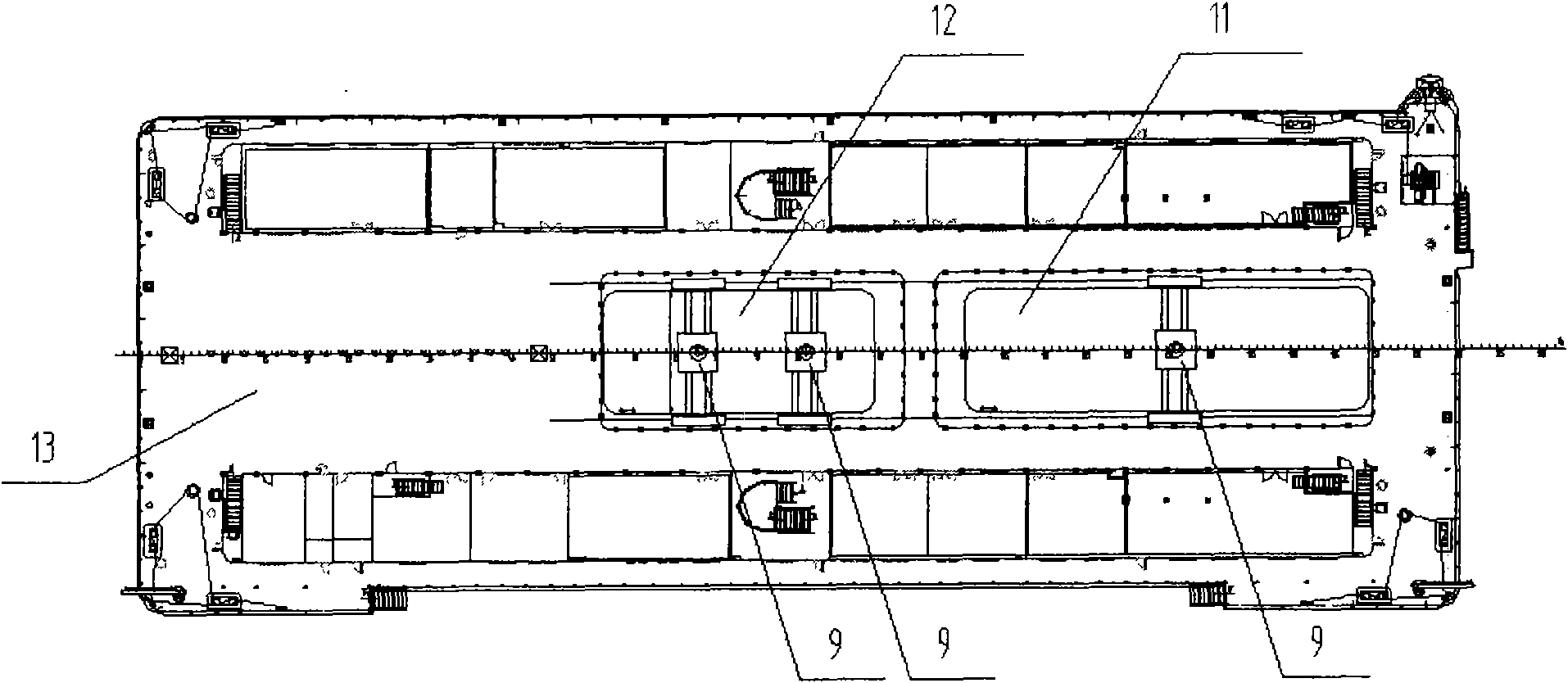

[0019] Such as figure 1 As shown, the multifunctional measurement area design method of the underwater acoustic measurement test ship of the present embodiment, the steps are: first, according to the requirements of the underwater acoustic measurement test, comprehensively consider the requirements for hoisting the tested equipment and test equipment, the area requirements of the test operation area, The area requirements of the test room, the area requirements of the living and resting area of the testers, etc., preliminarily determine the main dimensions of the underwater acoustic measurement test ship and the distance between the two pieces 1; then combine the division and layout of each functional measurement area to formulate a preliminary line design plan and the overall layout plan; then carry out the refinement of the overall plan design, and improve the measurement area design plan according to the test and test requirements and procedures of the tested equipment and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com