Diesel engine water pump pump water test bench

A technology of pump water test and diesel engine, applied in pump test, mechanical equipment, machine/engine, etc., can solve problems such as difficult water pump pump water test, and achieve the effect of good fixation and test work and good structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

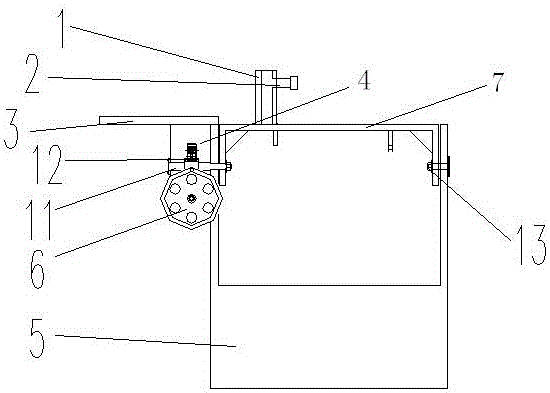

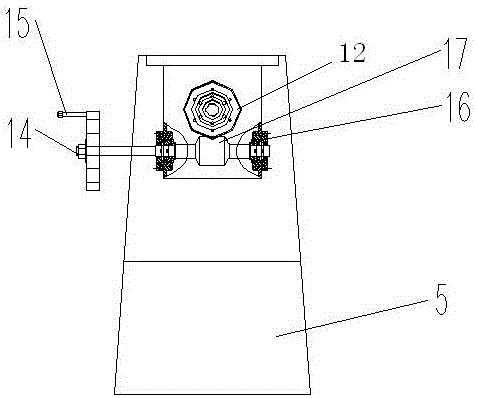

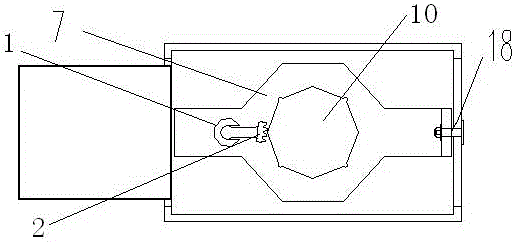

[0014] Such as figure 1 , 2 , 3, an embodiment of the present invention.

[0015] The waste water collection box 5 is welded with a 5mm thick steel plate to collect the waste water after the pumping. The waste water collection box 5 is designed as a trapezoidal structure with a small top and a big bottom. figure 2 , such a design can improve the rigidity of the overall structure, so that the water pump will not overturn when it rotates, and can appropriately reduce the volume. The upper plane on one side of the waste water collection box 5 is provided with a storage platform 3, see figure 1 , used to store the tools and materials needed for the pump water test.

[0016] The side of waste water collection box 5 is arranged with worm gear and worm transmission box 4, and worm gear and worm transmission box 4 is provided with worm shaft 17, worm gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com