Plate heat exchanger

A plate heat exchanger and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of high equipment manufacturing cost, larger equipment volume, and bulky equipment, etc. Effects of increased turbulence, reduced overall volume, and ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

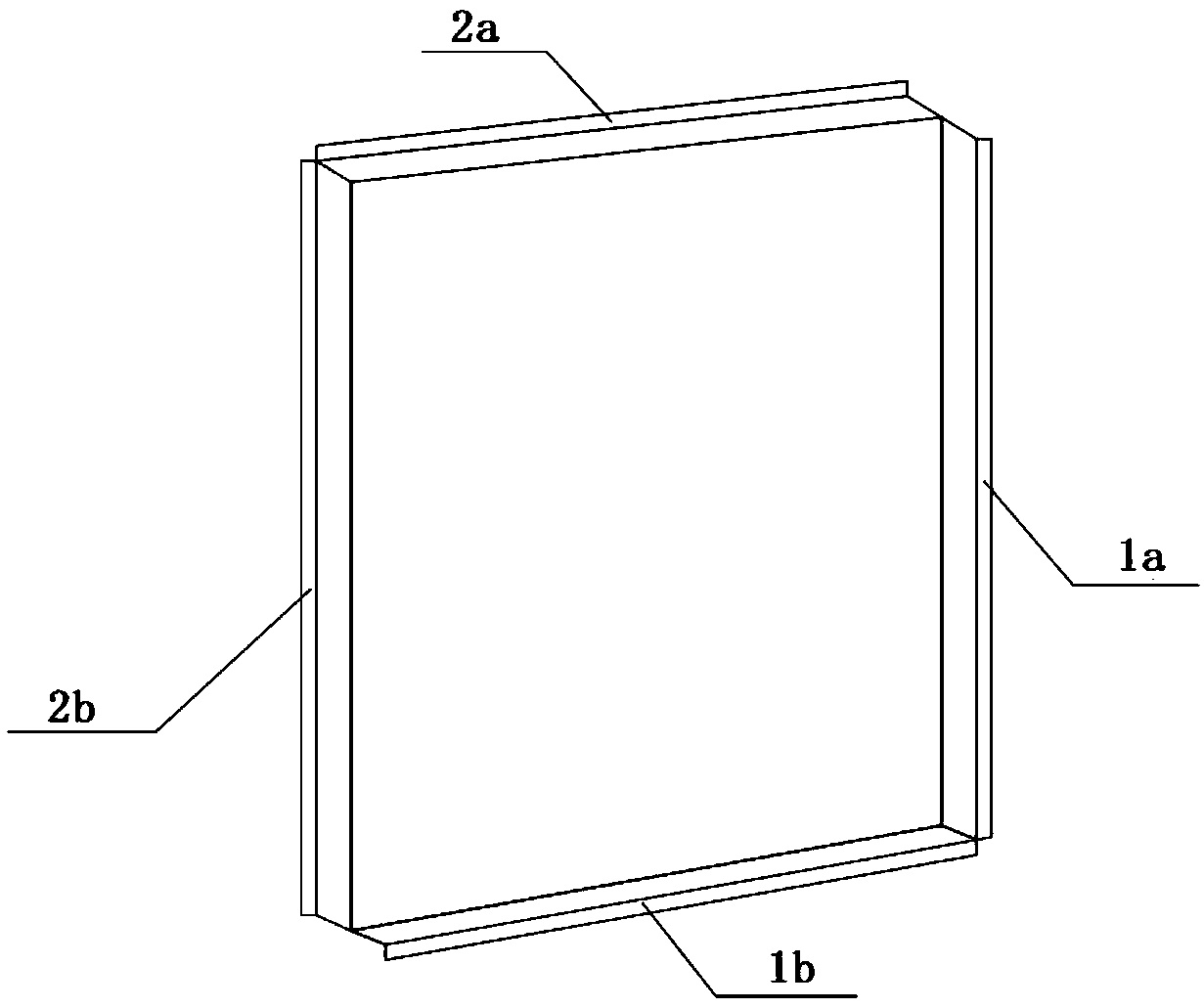

[0043] Such as figure 2 As shown, Embodiment 1 discloses a plate heat exchange sheet (ie heat exchange plate), by improving the hemming direction of the traditional plate (plate type) heat exchanger sheet, from the traditional non-adjacent two The positive and non-adjacent two reverse folds are changed into adjacent two positive and adjacent two reverse folds.

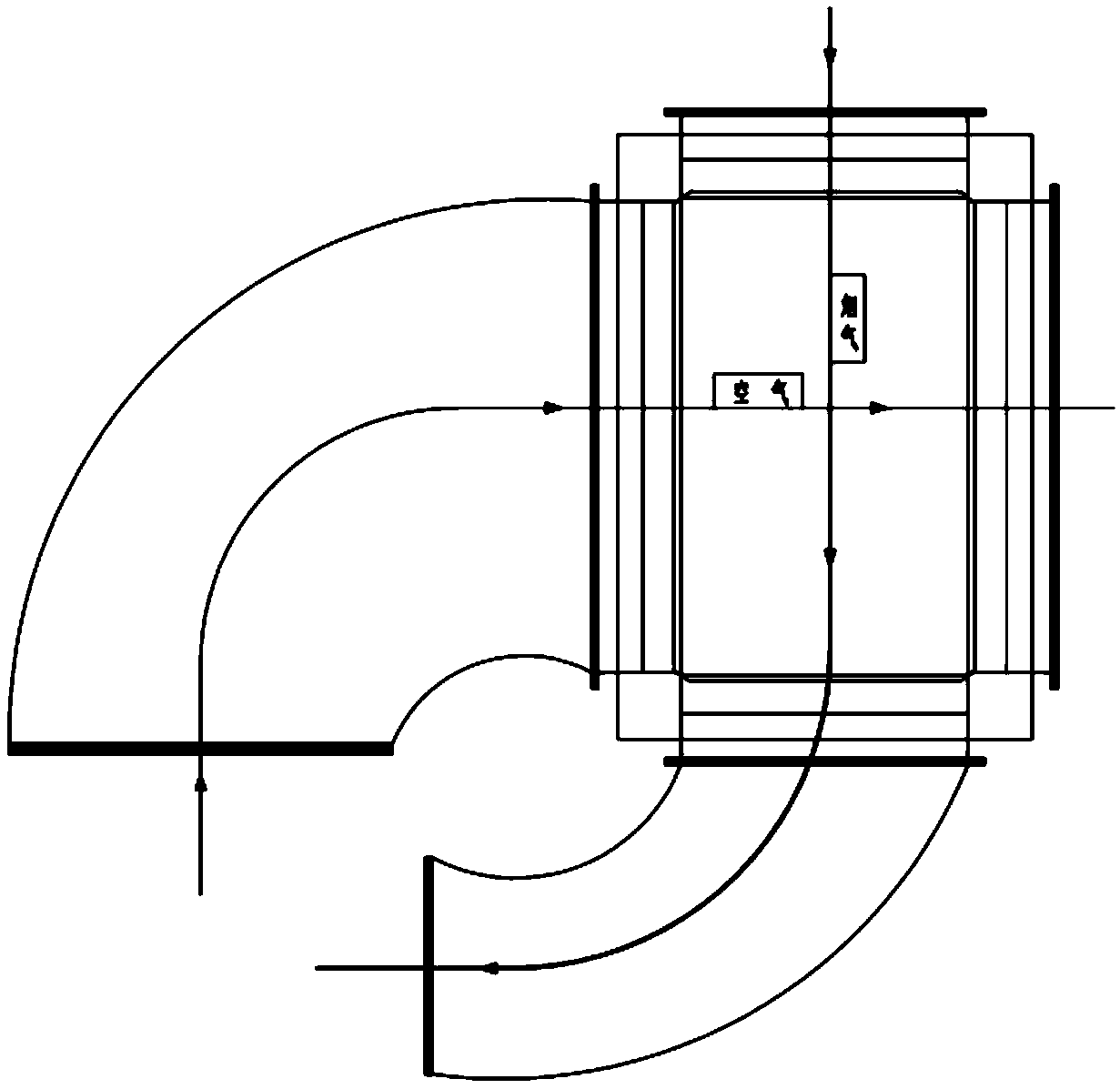

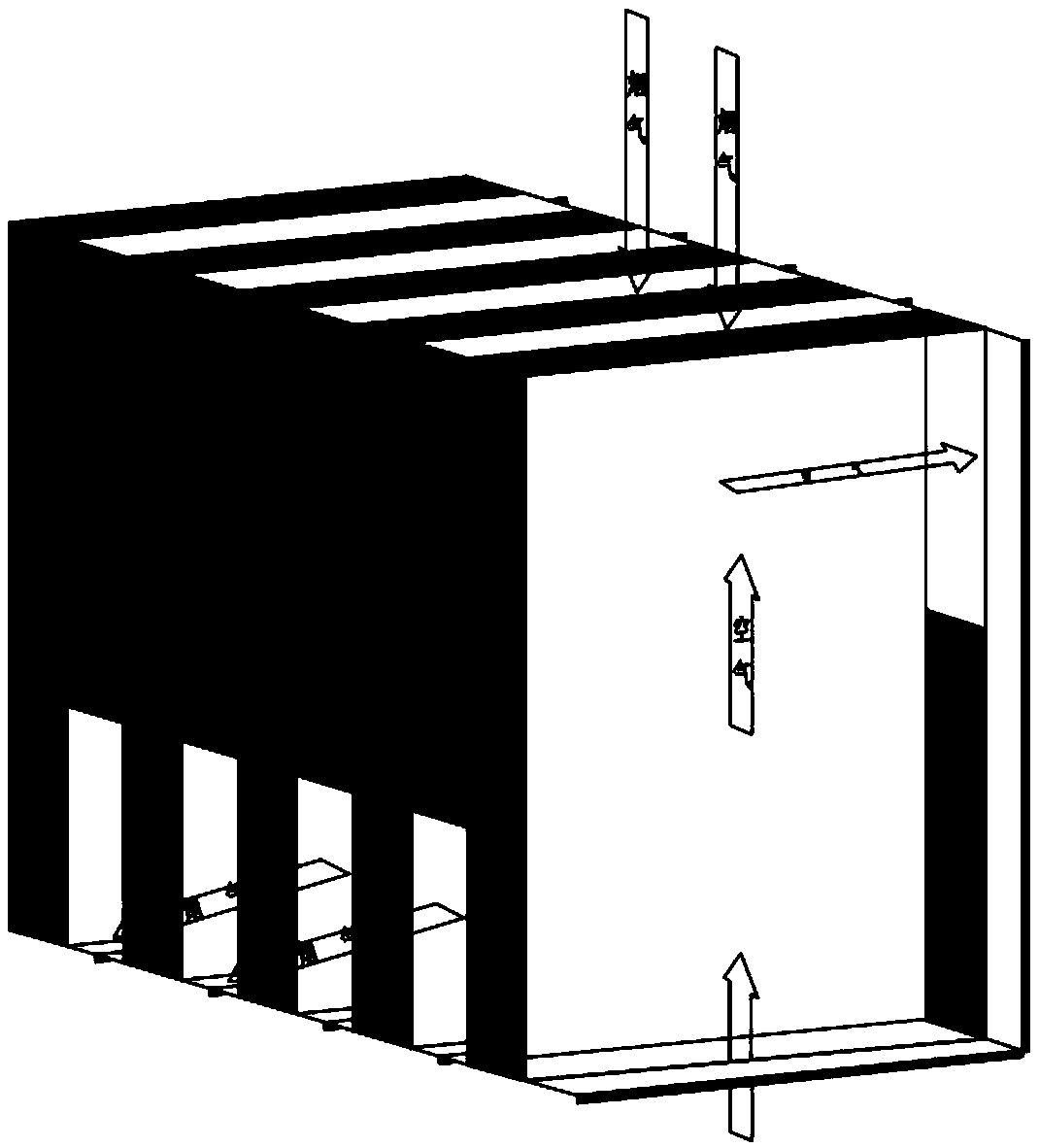

[0044] The two plate-type heat exchange fins described in Example 1 are stacked and two adjacent positive folds are butted and welded together to form a heat exchange plate bundle. The adjacent two sides of the heat exchange plate bundle are closed, and the other two sides communicate with each other to form a first medium passage for gas flow. Repeating this process, the plate heat exchange fins are welded in pairs to form a plurality of heat exchange plate bundles, and each heat exchange plate bundle has a first medium channel. Place the two heat exchange plate bundles facing each other, and butt and weld the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com