Pump cover and manufacturing method thereof

A technology of pump cover and metal skeleton, which is applied in the direction of pump components, variable displacement pump parts, and parts of pumping devices for elastic fluids, etc., which can solve the problem that the metal skeleton of the pump cover and the lining material are not tightly combined and shorten the product Insufficient service life and tensile strength, etc., to avoid air holes and cracks, prolong service life, and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

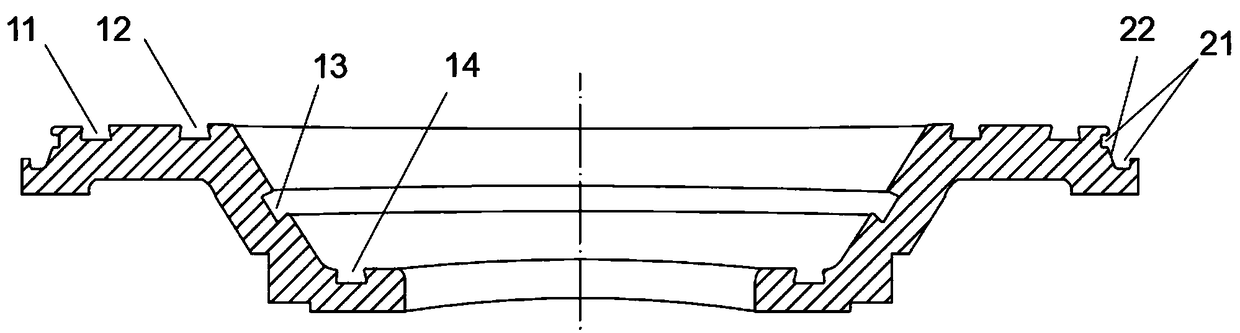

[0040] The following describes the technical solutions of the present invention in detail through specific embodiments in conjunction with the accompanying drawings.

[0041] In this embodiment, for the convenience of viewing the drawings and text description, the non-metallic lining layer is omitted here, but as a part of the pump cover, the non-metallic lining layer is completely filled in the groove I1 and the transition structure 2, And cover the inner side of the metal skeleton layer.

[0042] The metal skeleton layer is made of corrosion-resistant stainless steel by die-casting and finishing; the non-metallic lining material is a mixture of phenolic resin and silicon carbide ceramics, and the mass ratio of phenolic resin to silicon carbide ceramics is 1:0.5- 2.

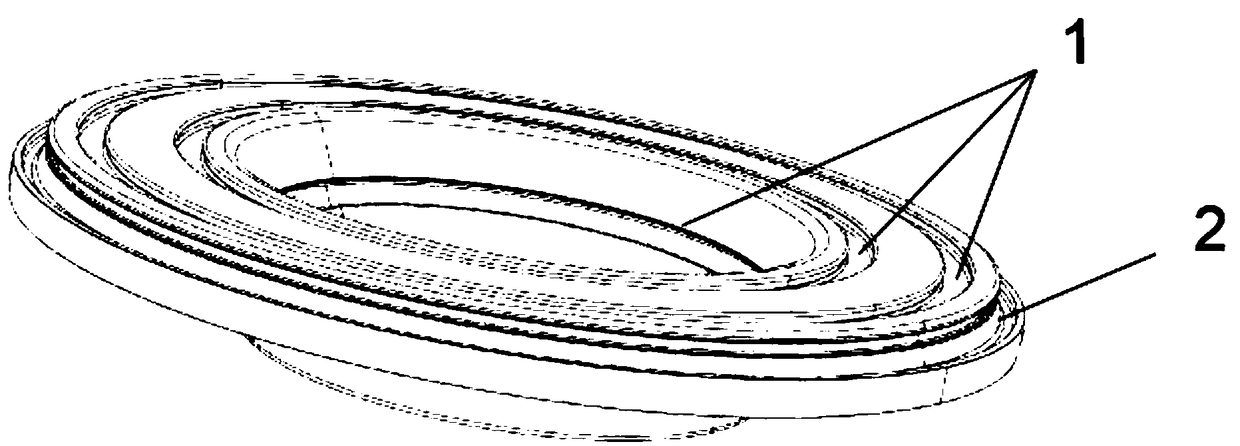

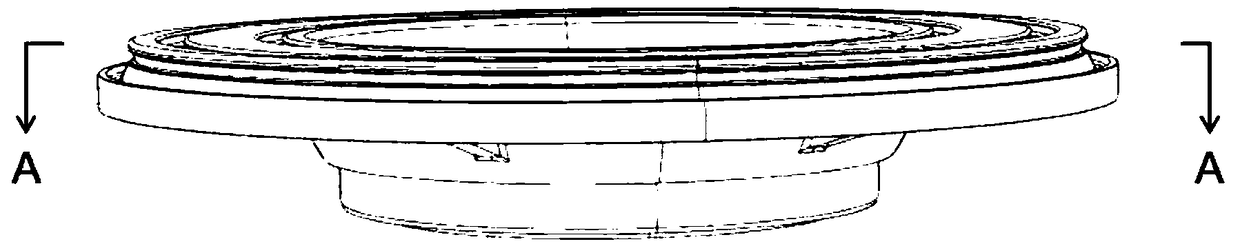

[0043] like figure 1 and 2 As shown, the inner surface of the metal skeleton layer is in a "concave" shape, a transition structure is arranged at the outer edge of the inner surface, and two grooves I11 and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com