Fracturing sliding sleeve and fracturing pipe string including fracturing sliding sleeve

A technology for fracturing sliding sleeves and inner sleeves, which is applied in the direction of casing, drill pipe, wellbore/well valve device, etc., and can solve the problems of high cost, long cycle, and affecting the running of downhole tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

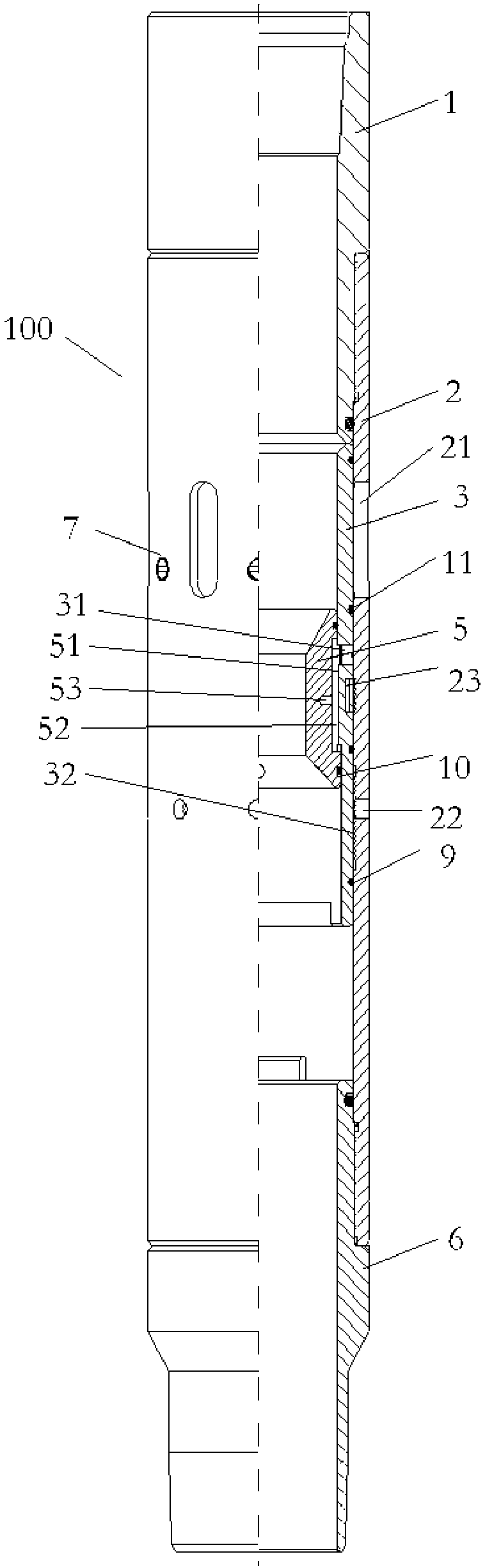

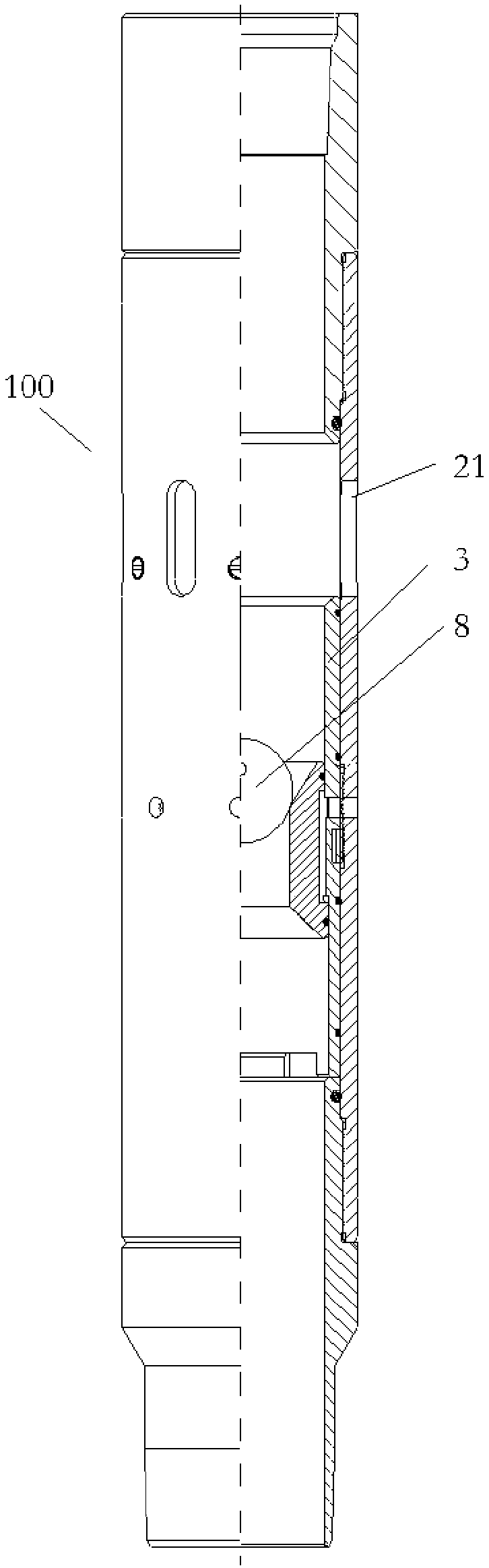

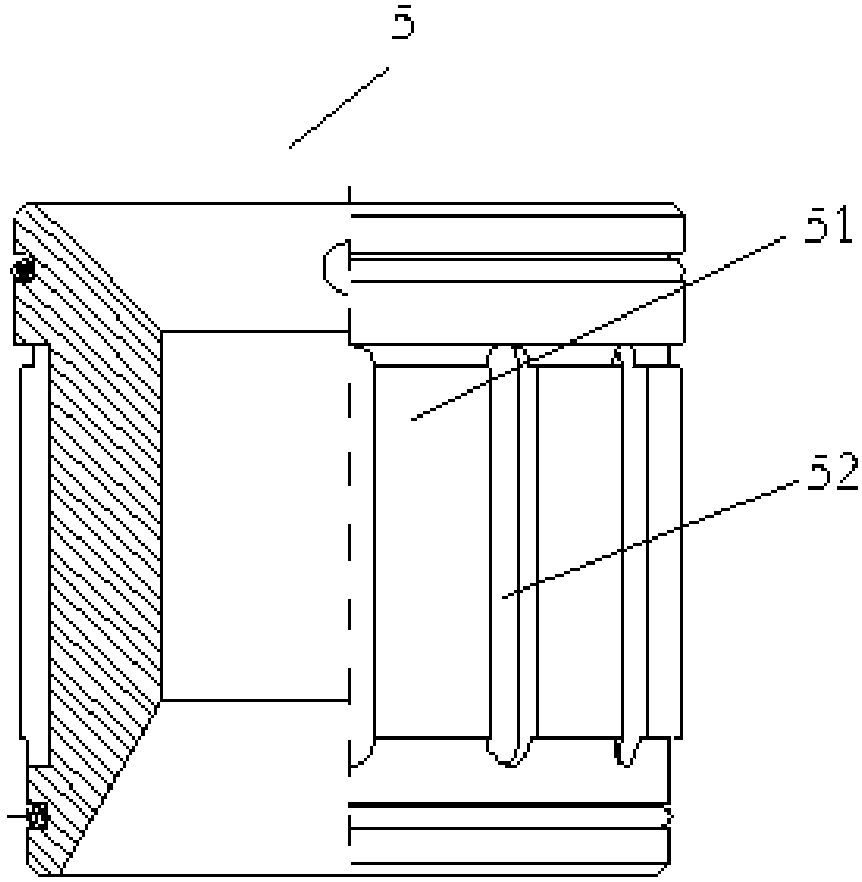

[0028] figure 1 and figure 2 Different states of the frac sleeve 100 according to the present invention are shown. Such as figure 1 and 2 As shown, the fracturing sliding sleeve 100 includes an outer shell 2 , an inner sleeve 3 , a ball seat 5 and a ball 8 . Wherein, the casing 2 is cylindrical, and a circulation hole 21 communicating with the inside and the outside is provided on the wall thereof, so as to transport the fracturing fluid to the outside. The inner sleeve 3 is arranged in the inner cavity of the outer shell 2, and is used to block the circulation hole 21 in the initial state, such as figure 1 shown. Under the action of hydraulic pressure, the inner casing 3 can move relative to the outer casing 2 to expose the circulation hole 21. In this case, the fracturing operation can be performed, such as figure 2 shown. The ball seat 5 is fixedly arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com