Cocoon laying device of hot air cocoon drying machine

A technology for drying and laying cocoons, applied in mechanical processing, silk fiber production, textile and papermaking, etc., can solve the problems of time-consuming and laborious, affecting the quality of drying cocoons, and it is difficult to ensure the orderly laying of cocoons, and achieve the effect of high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

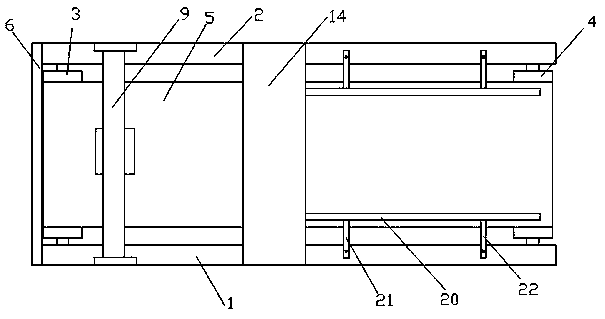

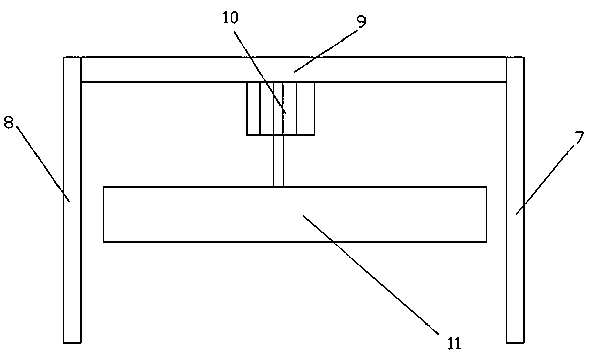

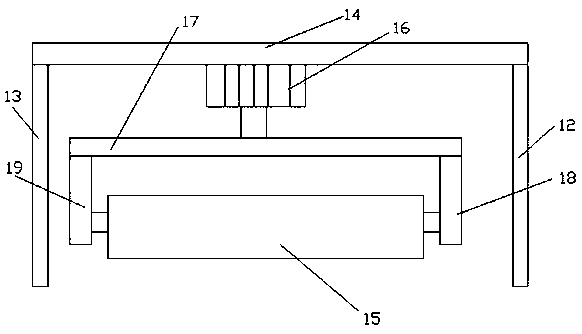

[0027] Such as Figure 1-3 As shown, the technical solution of the present invention is: a cocoon laying device of a hot-air cocoon drying machine, comprising a front plate 1 and a rear plate 2, and a transmission mechanism is provided between the front plate 1 and the rear plate 2. A blocking mechanism, a leveling mechanism and a limiting mechanism are arranged in order from left to right above the conveying mechanism;

[0028] The conveying mechanism includes a first conveying roller 3, a second conveying roller 4, and a conveying belt 5. The two ends of the first conveying roller 3 are respectively arranged on the front plate 1 and the rear through a first front shaft and a first rear shaft. On the plate 2, the first front axle, the first rear axle, and the front plate 1 and the rear plate 2 are all provided with first bearings, and the first rear axle passes through the rear plate 2 and is connected to the transmission motor , The two ends of the second conveying roller 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com