A kind of external rubber material for flame-retardant red fire-fighting rubber hose and its preparation process

A rubber hose and fire-fighting technology, which is applied to hoses, pipes, mechanical equipment, etc., can solve the problems of toxic gas generation and easy burning of the outer rubber layer, and achieve the effects of prolonging service life, moderate deformation, and high vulcanization safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

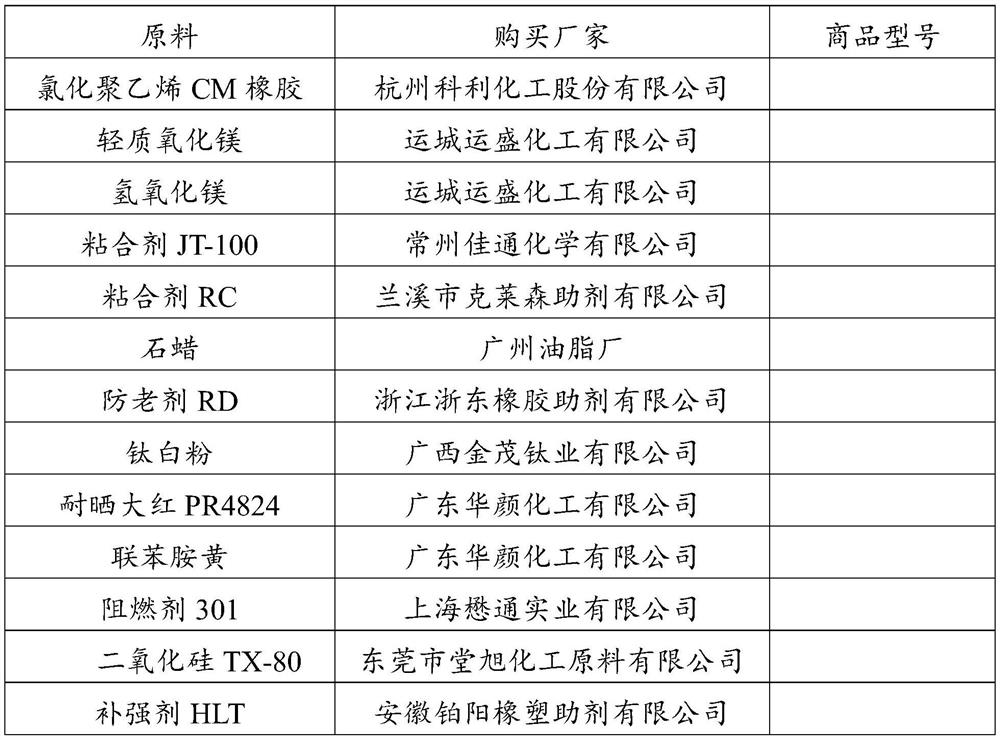

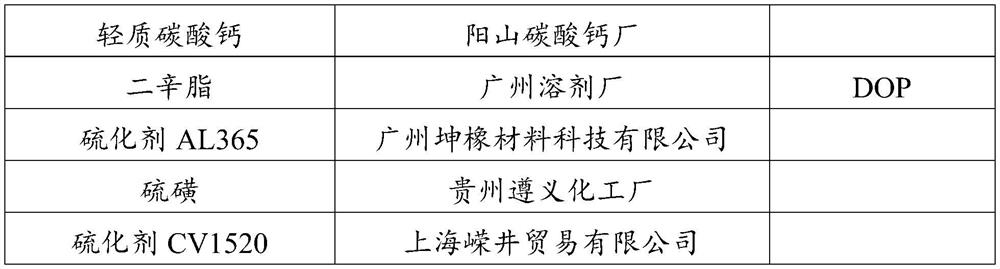

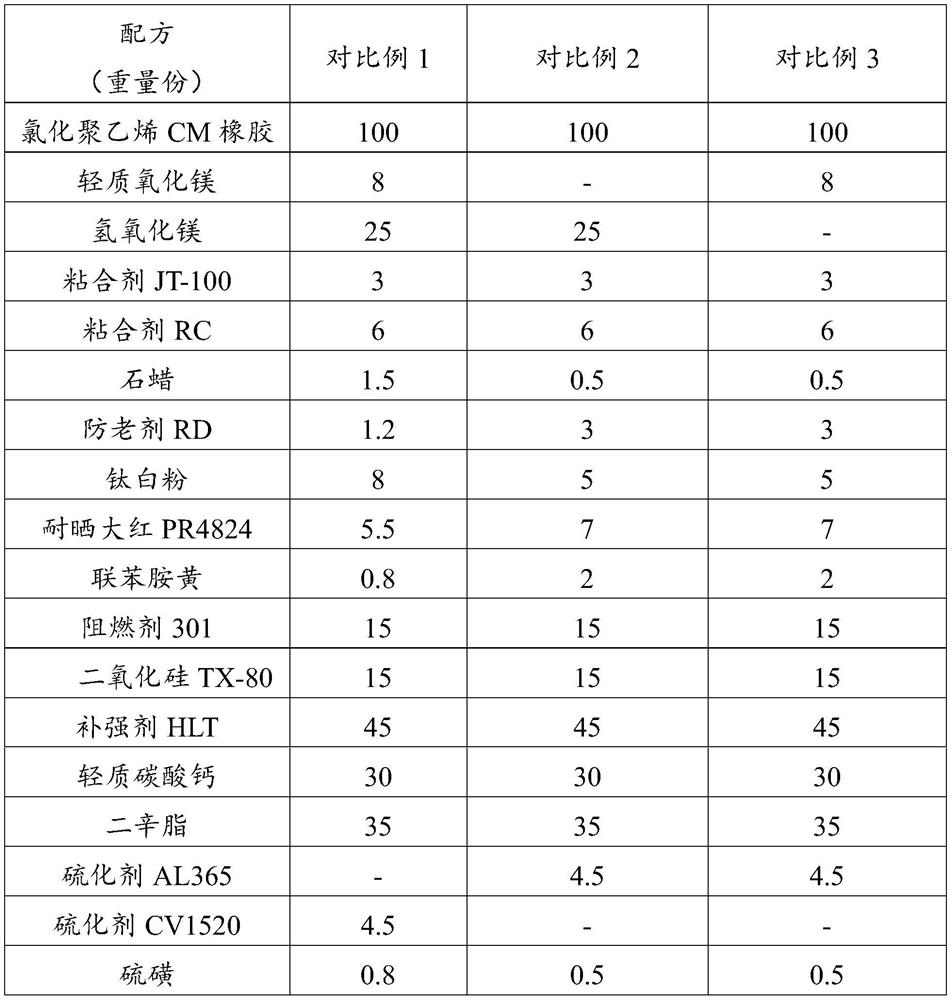

Method used

Image

Examples

Embodiment 1

[0025] This embodiment 1 provides an outer rubber material for a flame-retardant red fire-fighting rubber hose, which includes the following components in parts by weight: 100 parts of chlorinated polyethylene CM rubber, 12 parts of light magnesium oxide, 20 parts of magnesium hydroxide, 5 parts of adhesive JT-100, 5 parts of adhesive RC, 1 part of paraffin, 1 part of anti-aging agent RD, 6 parts of titanium dioxide, 5 parts of sunfast red PR4824, 0.5 parts of benzidine yellow, 10 parts of flame retardant 301 , 20 parts of silicon dioxide TX-80, 40 parts of reinforcing agent HLT, 40 parts of light calcium carbonate, 32 parts of dioctyl ester, 5 parts of vulcanizing agent AL365 and 1 part of sulfur.

[0026] The preparation method of the outer rubber material for the rubber hose comprises the following steps:

[0027] (1) Except for the vulcanizing agent AL365 and sulfur, put the remaining components into the internal mixer and knead for 4 minutes, and the kneading temperature ...

Embodiment 2

[0032] This embodiment 2 provides an outer rubber material for a flame-retardant red fire-fighting rubber hose, which includes the following components in parts by weight: 100 parts of chlorinated polyethylene CM rubber, 8 parts of light magnesium oxide, 25 parts of magnesium hydroxide, 3 parts of adhesive JT-100, 6 parts of adhesive RC, 1.5 parts of paraffin, 1.2 parts of anti-aging agent RD, 8 parts of titanium dioxide, 5.5 parts of sunfast red PR4824, 0.8 parts of benzidine yellow, 15 parts of flame retardant 301, 15 parts of silica TX-80, 45 parts of reinforcing agent HLT, 30 parts of light calcium carbonate, 35 parts of dioctyl ester, 4.5 parts of vulcanizing agent AL365 and 0.8 parts of sulfur.

[0033] The preparation method of the outer rubber material for the rubber hose comprises the following steps:

[0034] (1) Except for the vulcanizing agent AL365 and sulfur, put the remaining components into the internal mixer and knead for 5 minutes, and the kneading temperatur...

Embodiment 3

[0039] This embodiment 3 provides an outer rubber material for a flame-retardant red fire-fighting rubber hose, which includes the following components in parts by weight: 100 parts of chlorinated polyethylene CM rubber, 10 parts of light magnesium oxide, 22 parts of magnesium hydroxide, 4 parts of adhesive JT-100, 5.5 parts of adhesive RC, 0.8 parts of paraffin, 1.5 parts of anti-aging agent RD, 10 parts of titanium dioxide, 6 parts of sunfast red PR4824, 1 part of benzidine yellow, 13 parts of flame retardant 301 , 25 parts of silicon dioxide TX-80, 35 parts of reinforcing agent HLT, 35 parts of light calcium carbonate, 30 parts of dioctyl ester, 4 parts of vulcanizing agent AL365 and 1.2 parts of sulfur.

[0040] The preparation method of the outer rubber material for the rubber hose comprises the following steps:

[0041] (1) Except for the vulcanizing agent AL365 and sulfur, put the remaining components into the internal mixer and knead for 3 minutes, and the kneading tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com