Method for manufacturing exterior wall decorative board

A technology for decorative panels and exterior walls, applied in covering/lining, construction, building construction, etc., can solve the problems of glass curtain wall ceramic hanging panels, high-density exterior wall bricks, self-weight, wall crack resistance, weather resistance and durability protection performance Poor, comprehensive utilization rate is less than 15%, to achieve the effect of reducing efflorescence, good anti-fatigue performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A method of making an exterior wall decorative panel:

[0046] 1. Treatment of slag-coal gangue

[0047] 1) Prepare the alkaline activator: the weight ratio of caustic soda: sodium silicate: lime is 5:3.5:3.

[0048] 2) Preparation of decorative surface materials:

[0049] In parts by weight: 100 parts of slag, 25 parts of coal gangue, 12 parts of alkaline activator, 25 parts of water, 5 parts of pulp fiber, 5 parts of pigment, and 0.5 part of polypropylene fiber.

[0050] 3) Preparation of middle material layer materials:

[0051] In parts by weight: 100 parts of slag, 68 parts of coal gangue, 22 parts of alkaline activator, 40 parts of water, 35 parts of pulp fiber, and 1 part of polypropylene fiber.

[0052] Among the above components, the composition in the slag is: mass percent SiO 2 39%, FeO 0.8%, Al 2 o 3 15%, CaO41%.

[0053] The composition of coal gangue is: mass percent SiO 2 : 53.18%; Al 2 o 3 : 18.39%; Fe 2 o 3 : 12.63﹪; CaO: 2.32﹪; MgO: 2.21﹪; ...

Embodiment 2

[0063] A method of making an exterior wall decorative panel:

[0064] 1. Treatment of slag-coal gangue

[0065] 1) Prepare the alkaline activator: the weight ratio of caustic soda: sodium silicate: lime is 4:4.5:1.8.

[0066] 2) Preparation of decorative surface materials:

[0067] In parts by weight: 100 parts of slag, 48 parts of coal gangue, 24 parts of alkaline activator, 45 parts of water, 25 parts of pulp fiber, 10 parts of pigment, and 0.5 part of polypropylene fiber.

[0068] 3) Preparation of middle material layer materials:

[0069] In parts by weight: 100 parts of slag, 20 parts of coal gangue, 12 parts of alkaline activator, 34 parts of water, 15 parts of pulp fiber, and 1.5 parts of polypropylene fiber.

[0070] 2. Preparation of exterior wall decorative panels

[0071] 1) Add the decorative surface layer material and the middle material layer material into the mixer in the order of solution, powder and pulp fiber and stir for 10 minutes;

[0072] 2) Spray th...

Embodiment 3-14

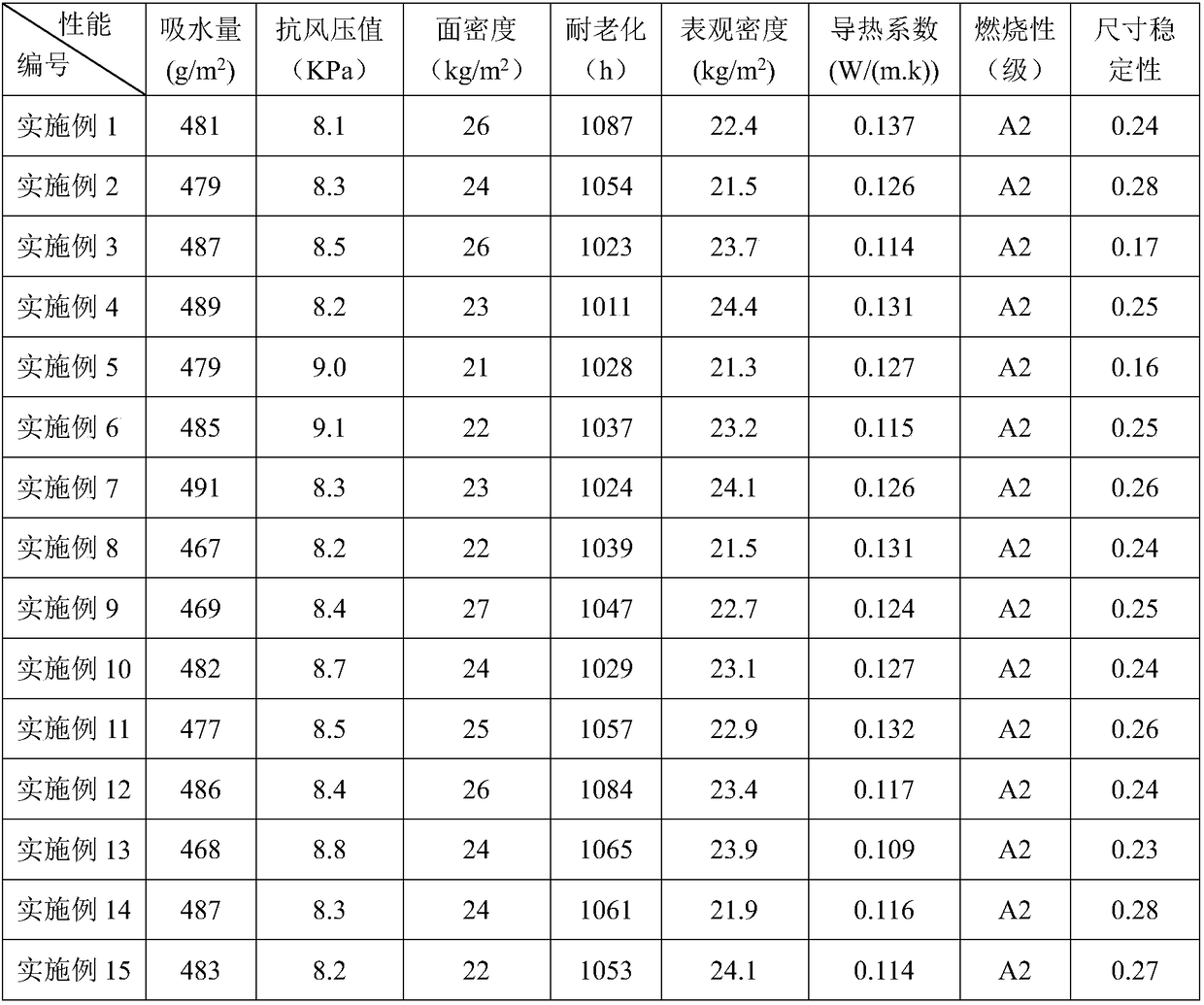

[0078] Embodiment 3-14 is as follows: (the preparation of basic activator is with embodiment 1, and preparation process is with embodiment 2)

[0079] Surface material preparation is as table 1: (by weight)

[0080] Table 1

[0081] Example number

slag

coal gangue

Alkaline Stimulator

water

pulp fiber

pigment

Polypropylene fibers

Example 3

100

40

11

24

28

15

0.5

Example 4

100

3

25

46

14

21

0.9

Example 5

100

34

7

20

9

30

0.7

Example 6

100

27

1

32

5

2

1.0

Example 7

100

0

9

50

13

10

0.6

Example 8

100

16

4

40

21

1

0.8

Example 9

100

50

19

28

19

26

0.7

Example 10

100

9

14

25

7

15

1.0

Example 11

100

19

12

48

24

28

0.8

Example 12

100

26

16

42

20

22

0.8

Example 13

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com