A liquid alkali-free quick-setting agent widely suitable for various types of cement

A technology of accelerator and cement, which is applied in the field of engineering construction, can solve the problems of poor adaptability of alkali-free accelerator to cement, achieve good storage stability, good construction environment, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

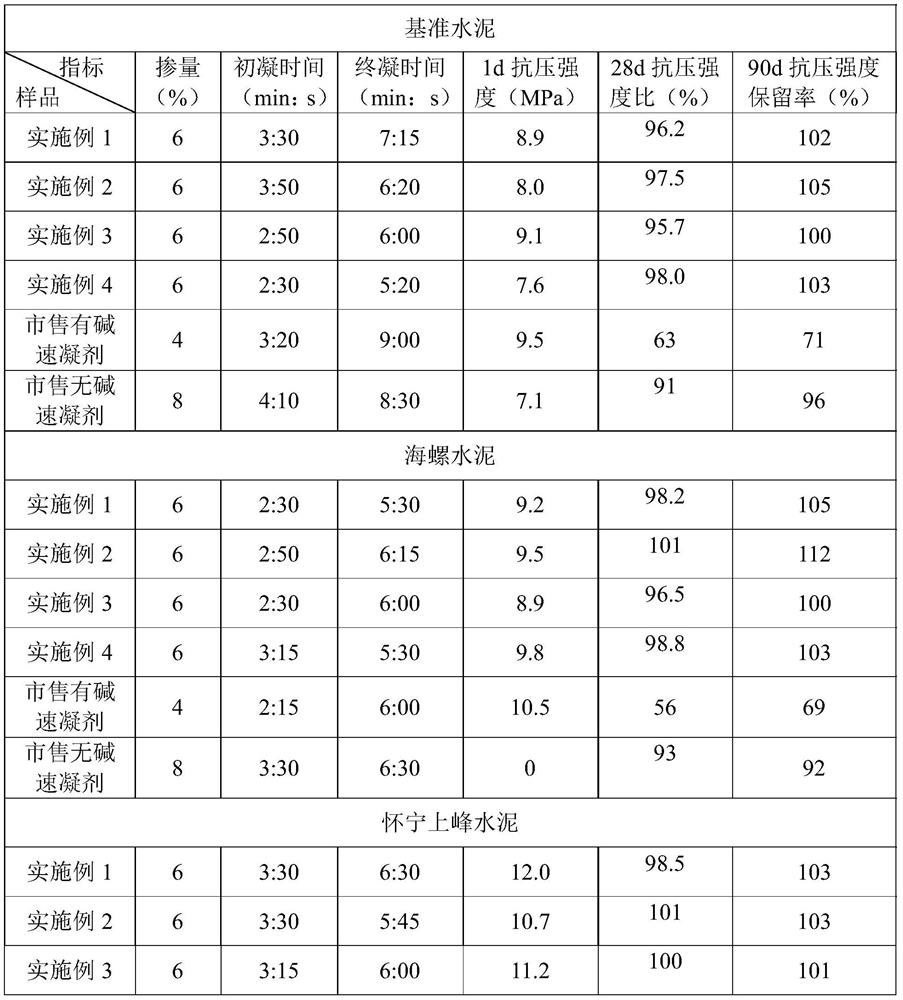

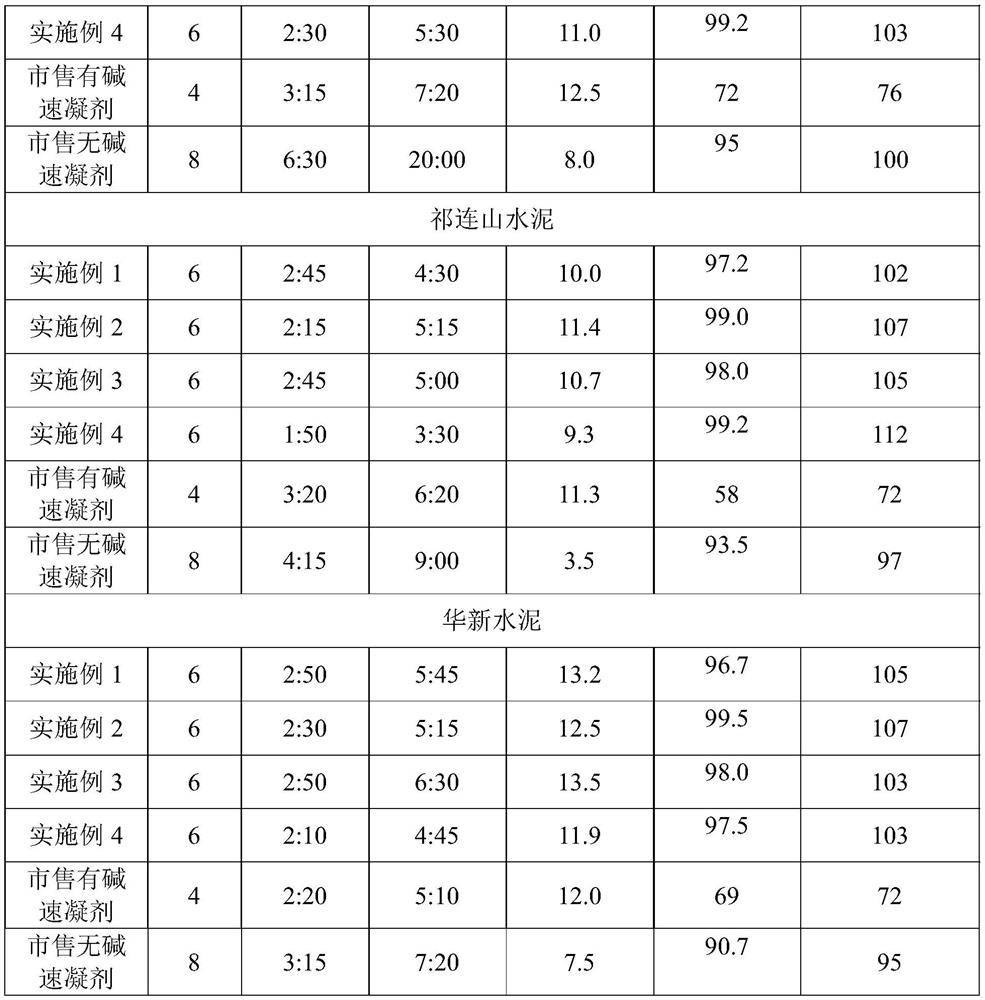

Examples

Embodiment 1

[0037] In a 250mL three-neck flask equipped with an electric stirrer and a thermometer, add 40g of amorphous aluminum hydroxide and 90g of hydrofluoric acid with a concentration of 40%, and stir until the solution is transparent to obtain an aluminum fluoride solution, which is discharged for later use.

[0038] In a 1000ml three-necked flask equipped with an electric stirrer and a thermometer, add 380g of deionized water, 400g of polyaluminum sulfate, 10g of magnesium fluorosilicate, 30g of triethanolamine, 45g of magnesium sulfate, 0.5g of phosphoric acid, 1g of ammonium monohydrogen phosphate, 1g of silicone defoamer, stir and heat to 80°C, keep warm for 2-3h, until it is completely dissolved and becomes a transparent solution, cool to below 40°C, add aluminum fluoride solution and stir evenly to obtain a liquid alkali-free accelerator.

[0039] The liquid alkali-free accelerator has a pH value of 1-4 and an alkali equivalent of ≤1%. The appearance is a transparent liquid, ...

Embodiment 2

[0041] In a 250ml three-necked flask equipped with an electric stirrer and a thermometer, add 40g of amorphous aluminum hydroxide and 90g of hydrofluoric acid with a concentration of 40%, and stir until the solution is transparent to obtain an aluminum fluoride solution, which is discharged for later use.

[0042] Add 380g of deionized water, 400g of polyaluminum sulfate, 30g of ferric sulfate, 5g of magnesium fluorosilicate, 5g of zinc fluorosilicate, 20g of triethanolamine, and 10g of triisopropyl in a 1000ml three-necked flask equipped with an electric stirrer and a thermometer. Alcohol amine, 20g urea, 2g lactic acid, 1g ammonium monohydrogen phosphate, 1g polyether defoamer, stir and heat to 80°C, keep warm for 2-3h, make it completely dissolved and become a transparent solution, cool to below 40°C, add fluorine The aluminum solution is stirred evenly to obtain a liquid alkali-free accelerator.

[0043] The liquid alkali-free accelerator has a pH value of 1-4 and an alkal...

Embodiment 3

[0045] In a 250ml three-neck flask equipped with an electric stirrer and a thermometer, add 50g of amorphous aluminum hydroxide and 110g of hydrofluoric acid with a concentration of 40%, stir until the solution is transparent to obtain an aluminum fluoride solution, and discharge it for later use.

[0046]Add 380g of deionized water, 400g of polyaluminum sulfate, 30g of ferric sulfate, 10g of magnesium fluorosilicate, 30g of triethanolamine, 45g of magnesium sulfate, 0.5g of phosphoric acid, and 1g of phosphoric acid in a 1000ml three-necked flask equipped with an electric stirrer and a thermometer. Ammonium monohydrogen, 1g organic silicon defoamer, stir and heat to 80°C, keep warm for 2-3h, make it completely dissolved and become a transparent solution, cool to below 40°C, add aluminum fluoride solution and stir evenly to obtain a liquid alkali-free coagulant.

[0047] The liquid alkali-free accelerator has a pH value of 1-4 and an alkali equivalent of ≤1%. The appearance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com