Sludge treatment system

A technology of sludge treatment and treatment method, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. The problems of difficult dehydration of the filter press and high personnel management costs have achieved the effect of convenient general layout layout, reduced scale, and low personnel management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

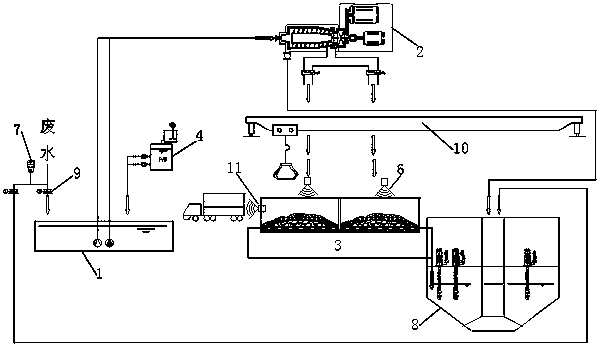

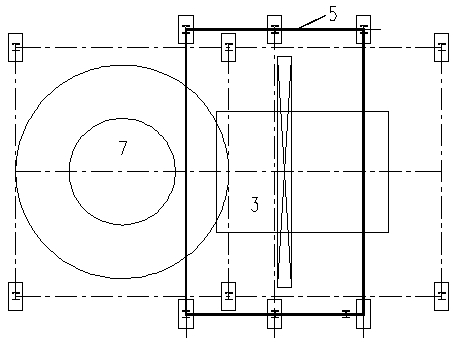

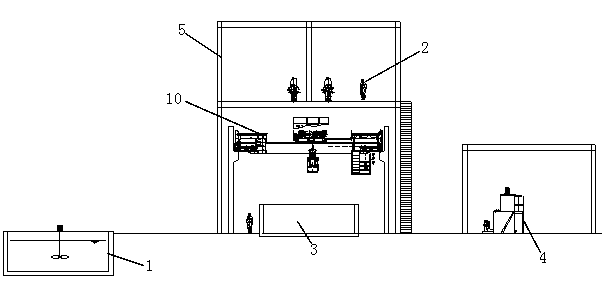

[0034] The following will combine figure 1 , figure 2 and image 3 The sludge treatment system and method provided by the present invention are described in detail, which is an available embodiment of the present invention, and it can be considered that those skilled in the art can modify and polish it within the scope of not changing the spirit and content of the present invention .

[0035] like figure 1 Shown: a sludge treatment system, which includes a regulating tank 1, a centrifugal dehydrator 2, a sludge tank 3, a station frame 5 and a dosing device 4, and the station frame is combined with a swirling well or an iron pit It is set up as two floors from top to bottom, the swirl well or iron sheet pit and the sludge tank are adjacently arranged and located on the bottom layer of the station building frame, and the centrifugal dehydrator is located on the second floor of the station building and above the sludge tank; The regulating tank, the centrifugal dehydrator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com