Hydroxylamine wastewater processing method

A treatment method, hydroxylamine technology, applied in water/sewage treatment, special compound water treatment, neutralized water/sewage treatment, etc., can solve the problems of high cost and large dosage, and achieve less solid waste and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

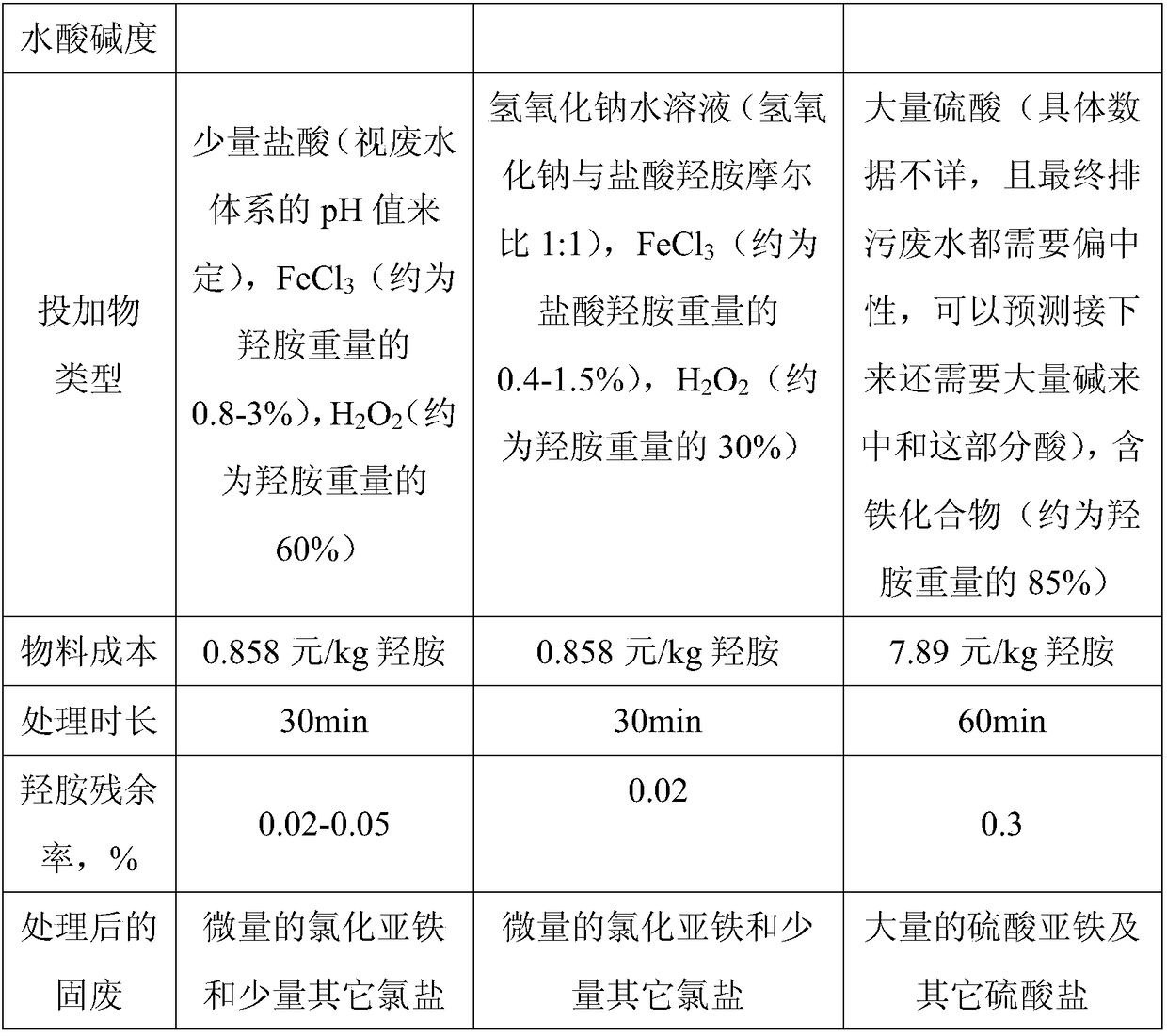

[0019] Embodiment 1: the treatment that contains hydroxylamine wastewater

[0020] Take 100g of wastewater containing hydroxylamine, the concentration of hydroxylamine is 5%, adjust the pH value to 7 with hydrochloric acid, add 0.2g of ferric chloride hexahydrate (containing 0.04g of ferric ion), stir for 0.5 hours, and slowly add 4g of it dropwise with a dropping funnel Hydrogen peroxide (30% concentration), during the dropping process, pay attention to controlling the rate of adding hydrogen peroxide, observe the temperature change of the feed liquid and the foam generated during the reaction, and prevent the temperature from being too high and the reaction speed from being too fast to cause the material to rush. After the dropwise addition, the stirring was continued until the exothermic reaction basically stopped, and the concentration of hydroxylamine was 0.002% for detection by sampling.

Embodiment 2

[0021] Embodiment 2: the treatment that contains hydroxylamine wastewater

[0022] Take 100g of wastewater containing hydroxylamine, the concentration of hydroxylamine is 10%, adjust the pH value to 6 with sulfuric acid, add 1.0g of ferric chloride hexahydrate (containing 0.21g of ferric ion), stir for 0.5 hours, and slowly add 8g of it dropwise with a dropping funnel Hydrogen peroxide (30% concentration), during the dropping process, pay attention to controlling the rate of adding hydrogen peroxide, observe the temperature change of the feed liquid and the foam generated during the reaction, and prevent the temperature from being too high and the reaction speed from being too fast to cause the material to rush. After the dropwise addition, the stirring was continued until the exothermic reaction basically stopped, and the concentration of hydroxylamine was 0.003% for detection by sampling.

Embodiment 3

[0023] Embodiment 3: the treatment that contains hydroxylamine wastewater

[0024] Take 100g of wastewater containing hydroxylamine, the concentration of hydroxylamine is 8%, adjust the pH value to 6.5 with hydrochloric acid, add 1.1g of ferric chloride hexahydrate (containing 0.24g of ferric ion), stir for 0.5 hours, and slowly add 5g of it dropwise with a dropping funnel Hydrogen peroxide (30% concentration), during the dropping process, pay attention to controlling the rate of adding hydrogen peroxide, observe the temperature change of the feed liquid and the foam generated during the reaction, and prevent the temperature from being too high and the reaction speed from being too fast to cause the material to rush. After the dropwise addition, the stirring was continued until the exothermic reaction basically stopped, and the concentration of hydroxylamine was 0.004% for detection by sampling.

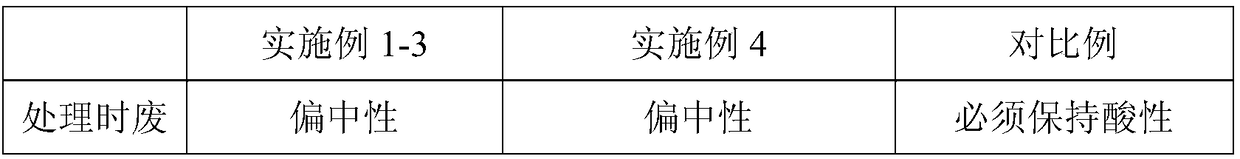

[0025] Embodiment 1-3 is three schemes of our scheme as representative, in test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com