Moving bed denitrification filter tank

A denitrification and moving bed technology, applied in anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of easily damaged filter material filtration level, complicated backwashing process, weakened filtration efficiency, etc. The effect of small backwashing difficulty, reducing damage and increasing filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

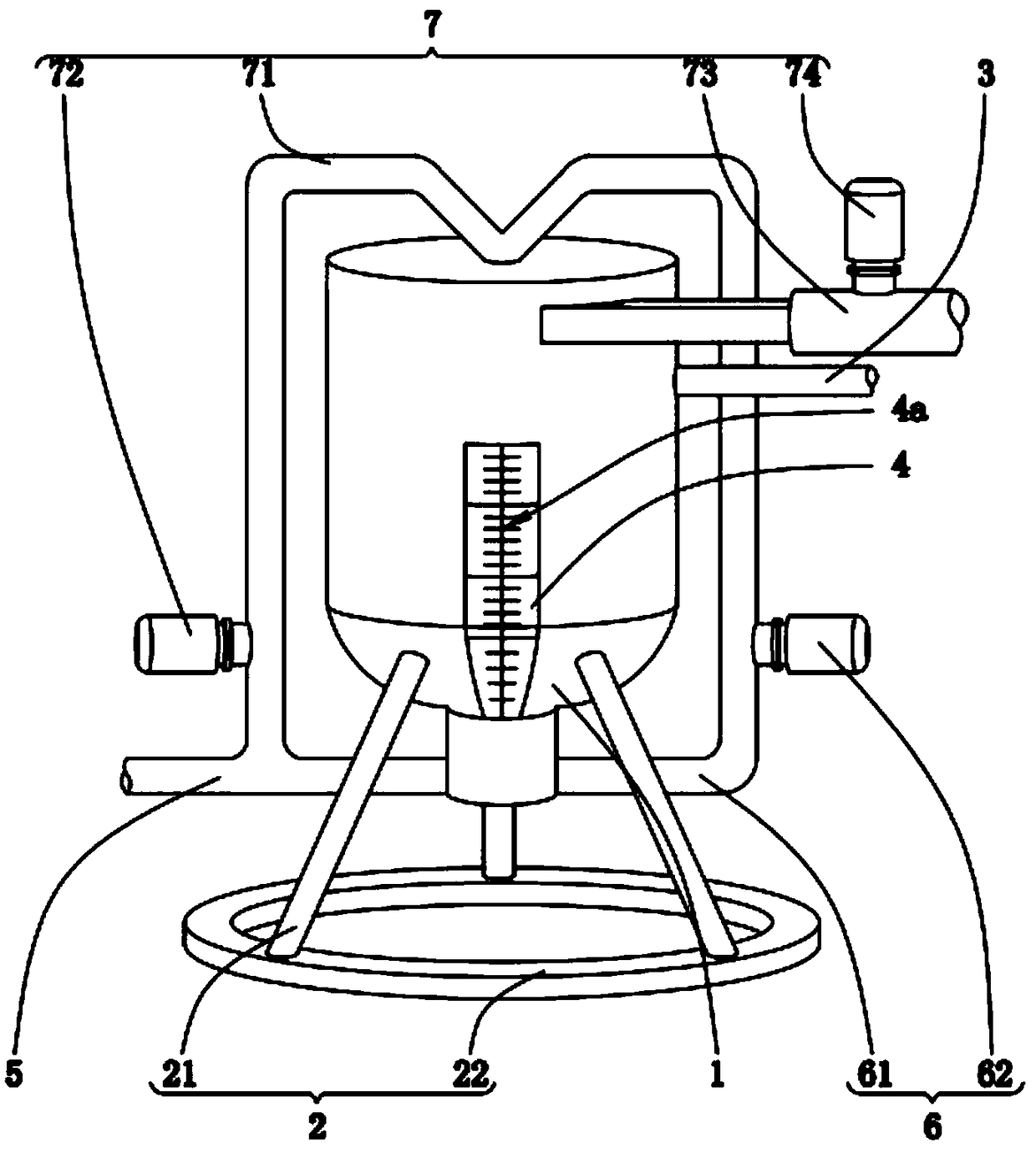

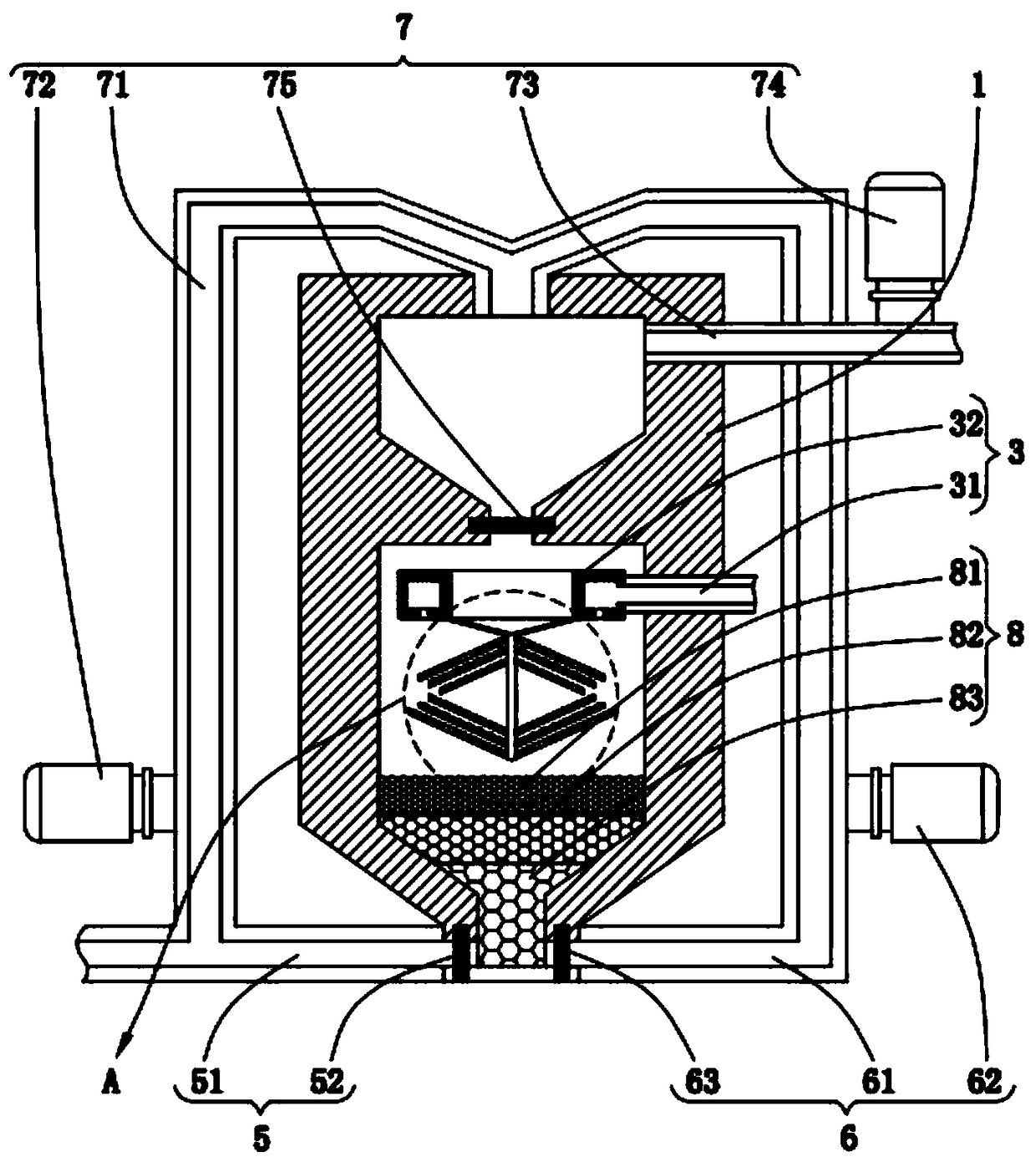

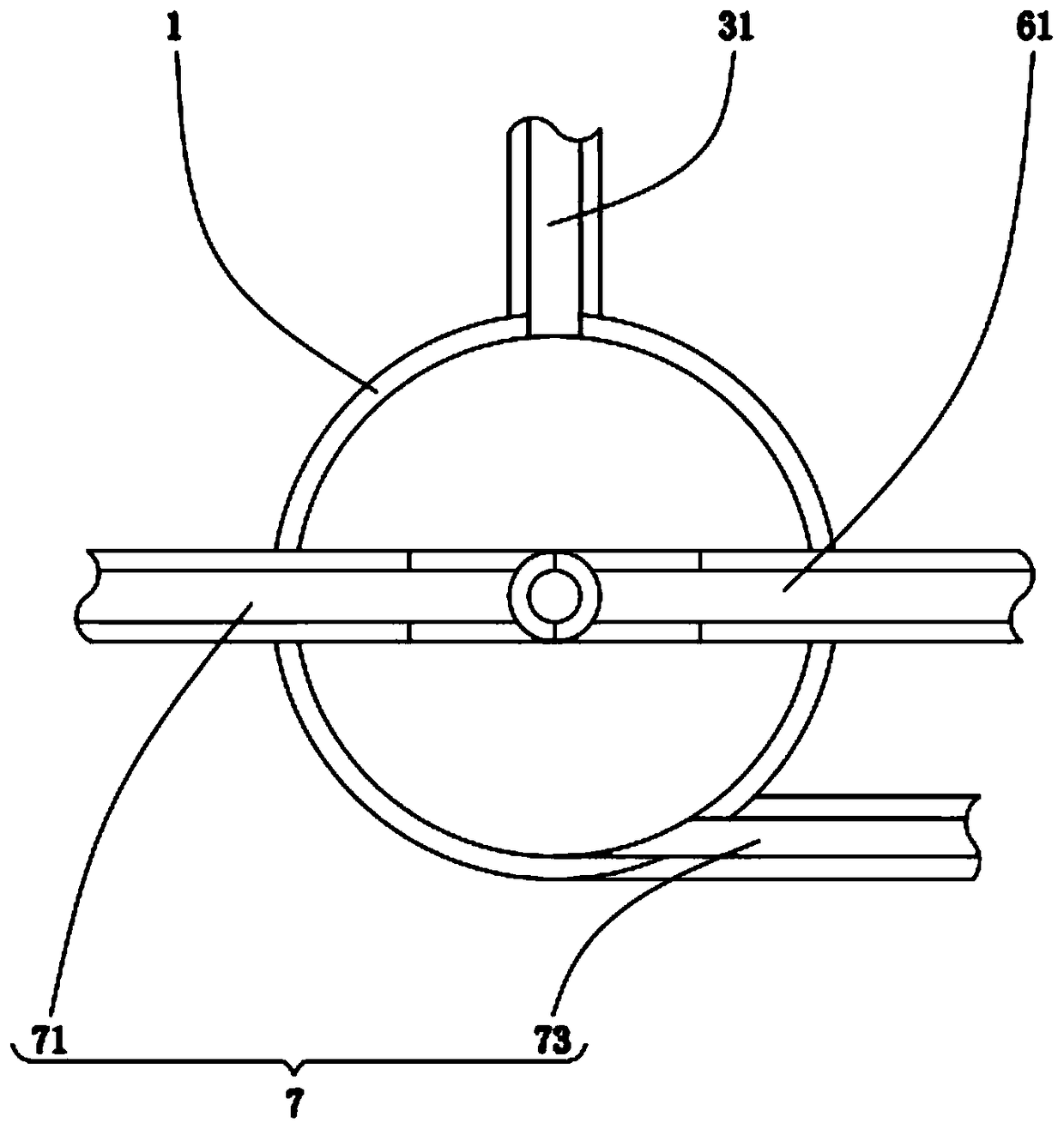

[0023] Such as Figure 1-Figure 4As shown, a moving bed denitrification and denitrification filter according to the present invention includes a filter housing 1, a support mechanism 2, a water inlet mechanism 3, an observation window 4, a drainage mechanism 5, a circulation mechanism 6, and a backwash mechanism 7. Filter mechanism 8 and distribution mechanism 9; the support mechanism 2 used to support and fix the filter housing 1 is connected to the bottom end of the filter housing 1; the filter mechanism used for filtering and denitrification 8 is located at the bottom of the inner cavity of the filter housing 1, and the filter mechanism 8 includes a first filter material 81, a second filter material 82 and a third filter material 83, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com